In the world of fluid management, choosing the right equipment is crucial. The Membrane Dosing Pump is often underestimated, yet it plays a vital role. These pumps deliver precise dosing for various applications, such as water treatment and chemical processing.

When selecting a Membrane Dosing Pump, you might encounter a variety of options that differ in quality and features. Some pumps excel in performance, while others may fall short. It’s essential to consider both reliability and efficiency. Many users find themselves confused when faced with technical specifications.

Identifying the best Membrane Dosing Pump involves understanding your specific needs. Flexibility in settings and ease of use are paramount. Sometimes, pump installations can present unforeseen challenges. This guide aims to simplify your decision-making process, ensuring you invest in the most suitable pump for your requirements.

Membrane dosing pumps are essential in various industries. They deliver precise amounts of liquid chemicals for treatment processes. These pumps are unique due to their design, which allows for accurate dosing. Users appreciate the ability to control flow rates. This versatility makes them suitable for water treatment, agriculture, and even food processing.

One key feature is their adjustable output. This can be critical in settings requiring precise chemical application. The ability to handle different viscosities is vital too. However, some users find the complexity daunting. Proper calibration is necessary to avoid over- or under-dosing. Maintenance can also be a concern; parts may wear over time. Regular inspections and timely replacements can help extend the pump's life.

Another notable benefit is the durability of these pumps. They can withstand harsh conditions without sacrificing performance. Many are resistant to corrosive substances. This feature enhances their appeal in challenging environments. Still, users should consider their specific needs before purchasing. Not every model may fit every application, leading to potential inefficiencies.

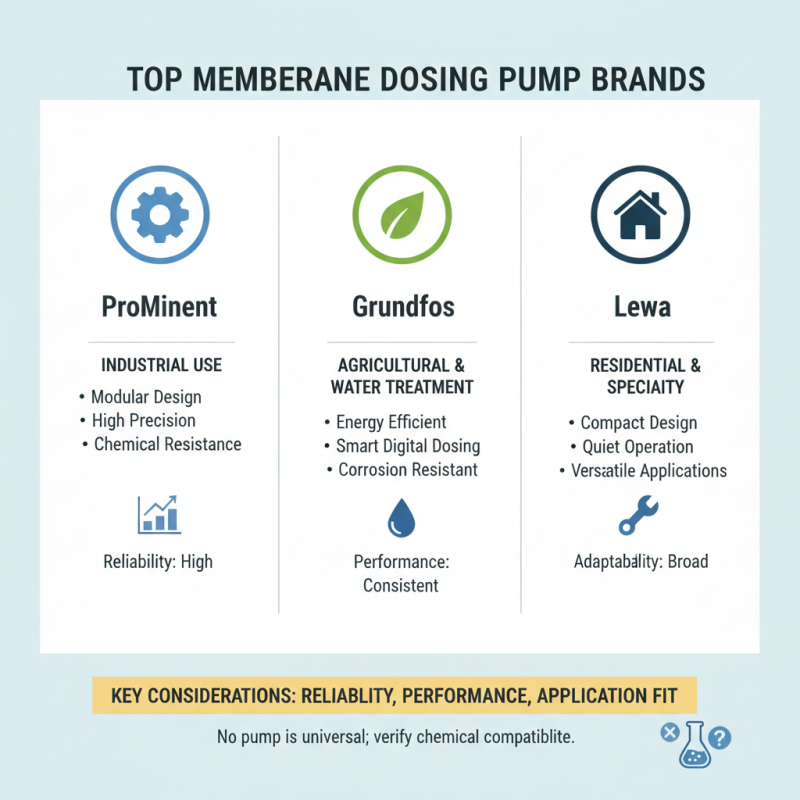

When exploring the best membrane dosing pumps, it's essential to consider the top brands. These brands stand out for their reliability and performance. Each offers unique features tailored to various applications. Some may focus on industrial needs, while others cater to agricultural or residential use. It's worth noting that no pump is perfect. Some may struggle with specific chemicals, impacting overall efficiency.

Understanding the features is crucial. Look for pumps with adjustable dosing rates. Ensure they come equipped with easy maintenance options. Often, users overlook the importance of compatibility with existing systems. Make sure to check the materials used in pump construction, as they affect durability and performance.

Tip: Pay attention to customer reviews. They can reveal both strengths and weaknesses. Sometimes, a highly-rated pump might not suit your specific needs. It’s also wise to consult with experts before making a purchase. This can help uncover potential issues you might face down the road. Look for user forums where experiences are shared.

When selecting the right membrane dosing pump, consider your specific needs. Identify the applications where you'll use the pump. Common uses include chemical dosing in water treatment and agriculture.

Tip: Assess the flow rate required for your project. Flow rates can vary significantly between models. Make sure to choose one that aligns with your demands.

Another crucial factor is the pressure range. Different applications need different pressures. Evaluate your system’s requirements carefully. An incorrect pressure range could lead to inefficiencies.

Tip: Always check compatibility with the chemicals you'll use. Different materials react differently. This consideration is key for ensuring longevity and performance.

Lastly, don't overlook the ease of maintenance. Some pumps require more upkeep than others. Think about how often you are willing to perform maintenance tasks. A more complex model may not be ideal if you're seeking convenience.

Tip: Read reviews from users. They can provide insights into real-world performance and potential issues.

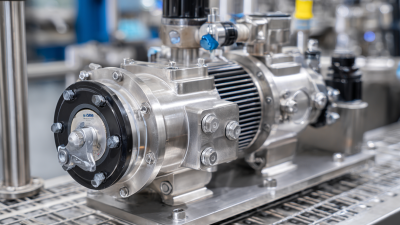

Membrane dosing pumps play a crucial role in various industries. Their installation requires careful planning. It is essential to ensure a stable base for the pump. Inaccurate positioning may cause excessive vibrations. According to industry reports, improper installation can reduce pump lifespan by up to 30%.

Maintenance is equally critical. Regular checks on seals and diaphragm integrity are necessary. Neglecting these can lead to leaks and reduced accuracy. A study found that maintenance costs can represent 20% of the total pump operating expenses. Adjusting the dosing rate correctly is vital too. Too high or too low adjustments impact performance. Sometimes, operators fail to make these necessary tweaks.

Periodic cleaning helps in maintaining optimal performance. Build-up inside the pump can hinder functionality. Depending on usage, a biannual or quarterly cleaning schedule is necessary. Operators often overlook this simple task. This negligence can lead to costly repairs or replacements.

| Model | Flow Rate (L/h) | Max Pressure (Bar) | Power Supply (V) | Weight (kg) | Features |

|---|---|---|---|---|---|

| Model A | 15 | 8 | 220 | 5.5 | Digital display, adjustable speed |

| Model B | 30 | 6 | 110 | 4.0 | Corrosion resistant, low noise |

| Model C | 25 | 10 | 230 | 6.0 | Self-priming, multi-functional |

| Model D | 20 | 5 | 220 | 4.5 | Compact design, easy installation |

| Model E | 10 | 7 | 120 | 3.0 | User-friendly controls, lightweight |

The membrane dosing pump market is experiencing significant growth. According to a recent industry report, the global market size is projected to reach $1.5 billion by 2026. This surge is driven by increasing demand for precise chemical dosing across various sectors, including water treatment and agriculture.

Top-selling membrane dosing pumps are designed for efficiency and reliability. They offer features like adjustable flow rates and integrated control systems. In many applications, accurate dosing can improve operational efficiency by up to 30%. However, not all models meet these performance standards. Consumers often find discrepancies in advertised specs and real-world results.

Another concern is maintenance. Many users report that regular upkeep is essential to maximize pump lifespan. Poor maintenance can lead to a decline in performance, resulting in unexpected costs. Potential buyers should weigh these factors carefully when exploring options. Balancing price with functionality can be challenging in a crowded market.