Dewatering Press Machines play a vital role in various industries. They efficiently remove excess water from materials. This process helps reduce weight and volume for easier handling. Industries such as agriculture, waste management, and food processing use these machines daily.

Understanding the benefits of a Dewatering Press Machine is essential. It not only saves energy but also lowers transportation costs. The machine's design allows for effective separation of solids from liquids. This efficiency can significantly improve productivity.

Despite these advantages, some may overlook potential drawbacks. Maintenance needs and operational costs can be higher than expected. Users must weigh the benefits against these challenges. Ultimately, investing in a Dewatering Press Machine can yield positive results when approached thoughtfully.

Dewatering press machines play a vital role in many industries. They separate liquid from solid materials efficiently. This is crucial for waste management and resource recovery. By compressing the materials, they reduce volume significantly. This not only saves space but also lowers transportation costs.

These machines are widely used in agriculture, food processing, and wastewater management. In food processing, they extract juice from fruits and vegetables. In wastewater treatment, they help eliminate excess water from sludge. This makes disposal easier and less harmful to the environment. However, not all materials dewater easily. Some require additional pre-treatment, which can complicate the process.

While the technology is effective, challenges remain. Sometimes, the quality of the output can vary. This may reflect imperfect operation or material properties. Regular maintenance is essential to ensure optimal performance. It is also important to assess the specific needs before investing in such machinery. Each application may demand a different approach to dewatering.

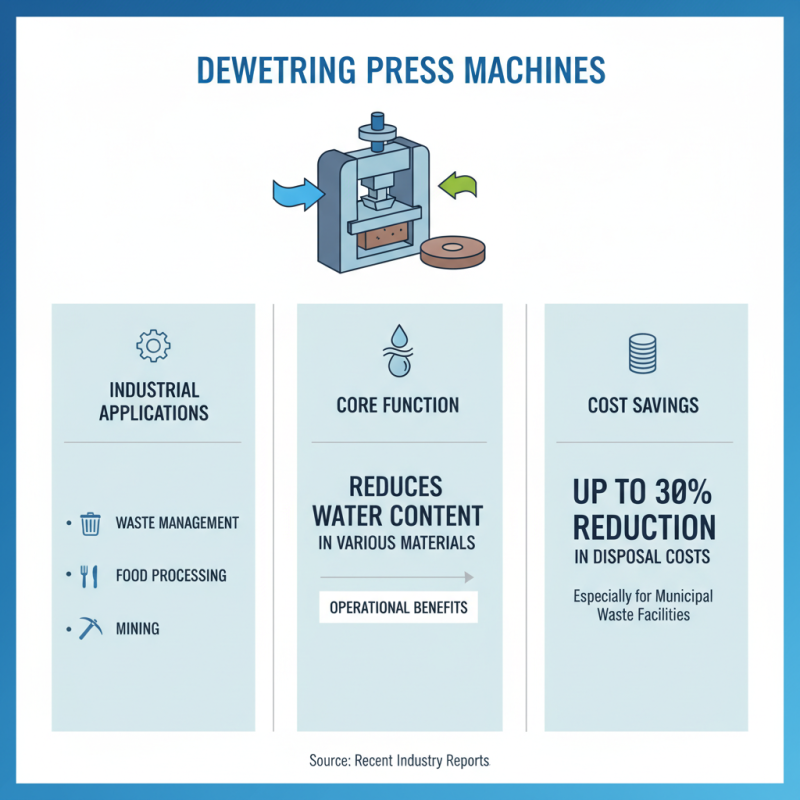

Dewatering press machines play a crucial role in industries such as waste management, food processing, and mining. These machines effectively reduce water content in various materials, leading to significant operational benefits. According to recent reports, companies can experience up to a 30% reduction in disposal costs when using dewatering press machines. This is especially impactful for municipal waste facilities.

The operational efficiency of dewatering presses results in enhanced productivity. They can process large volumes of material, freeing up valuable time and resources. Additionally, the reduced waste volume allows facilities to optimize their space. However, it is essential to consider the initial investment in these machines. Not all businesses may see immediate returns, which necessitates careful financial planning.

In the food industry, the benefits extend beyond cost savings. Dewatering presses allow for improved product quality. By reducing water content, the shelf life of products like fruits and vegetables increases. Reports suggest that food processors can enhance profitability by 25% through better waste management. Still, not all applications may yield such results, prompting a need for ongoing assessment and optimization.

Dewatering press machines play a crucial role in waste management. They efficiently remove excess water from various types of waste materials. This process reduces the volume and weight, making disposal easier and more economical. The machines are widely used in municipalities, food processing, and construction debris management.

In municipal waste management, dewatering presses help treat sewage sludge. By extracting water, they convert sludge into a manageable cake form. This cake can be further processed or disposed of safely. Food processing facilities benefit as well. By removing moisture from byproducts, they minimize waste and promote recycling. However, the initial investment and maintenance costs can be deterrents for some.

Construction sites also utilize dewatering presses. They help manage the water content in excavated soil and waste. Reducing water further allows for better reuse of materials. Yet, operators must ensure proper calibration and operation. Improper use can lead to inefficiencies and unexpected problems. Overall, these machines remain vital tools in promoting sustainable waste management practices.

Dewatering press machines offer several advantages over traditional water removal methods. One major benefit is their efficiency. These machines can extract moisture more quickly and effectively than manual methods. Operators can achieve better results in a shorter time frame. This efficiency translates to increased productivity, especially in large-scale applications.

In contrast, traditional methods often rely on gravity or manual labor. This can be time-consuming and labor-intensive. For instance, using a shovel to move wet materials is physically demanding. It can lead to inconsistent results. The risk of human error increases. Additionally, standard methods may require more space and resources. In crowded facilities, this can be a challenge.

While dewatering presses are effective, they also come with complexities. There may be a steep learning curve for operators. Regular maintenance is essential to keep these machines running smoothly. Neglecting this can lead to downtime or costly repairs. These factors should be considered when weighing options for dewatering processes.

| Feature | Dewatering Press Machines | Traditional Methods |

|---|---|---|

| Efficiency | High, up to 90% moisture reduction | Moderate, typically 50-70% |

| Energy Consumption | Low, optimized for performance | Higher, varies with method |

| Labor Requirement | Automated processes reduce labor | High, requires manual intervention |

| Footprint | Compact design saves space | Larger setups needed |

| Application Versatility | Suitable for various materials | Limited to specific types |

| Maintenance | Low maintenance required | Typically high maintenance |

The future of dewatering press technology is ripe with innovations. As industries grow, the need for efficient water removal increases. New designs are emerging that enhance performance and reduce energy use. These advancements focus on automation and smart technology integration, leading to improved operational efficiency.

Research is exploring sustainable materials for construction. This could lower environmental impact while maintaining strength. Additionally, machine learning algorithms are being used to optimize the dewatering process. Data collection can help predict maintenance needs, reducing downtime and costs. However, reliance on technology has its drawbacks, as not all users adapt successfully to these changes.

Incorporating user feedback into redesigns is essential. Some machines can be overly complex, making training necessary but time-consuming. Balancing innovation with usability remains a challenge. Ultimately, the future lies in creating machines that are powerful yet easy to operate, allowing all users to benefit effectively.