In the realm of fluid management, the significance of a reliable metering dosing pump cannot be overstated. According to a report by MarketsandMarkets, the global market for metering pumps is projected to reach USD 8.57 billion by 2025, reflecting a robust CAGR of 5.9% from 2020 to 2025. This growth underscores the increasing demand for efficient and precise chemical dosing in various industries, including water treatment, pharmaceuticals, and food processing. A key aspect that often dictates the choice of a metering dosing pump is its after-sales service and maintenance costs.

Industry studies reveal that nearly 30% of operational downtime can be attributed to pump failures, making reliable after-sales support crucial for ensuring uninterrupted operations and minimizing total cost of ownership. As end-users strive to optimize their processes, understanding the intricacies of these pumps, especially concerning after-sales services, becomes paramount for achieving long-term success.

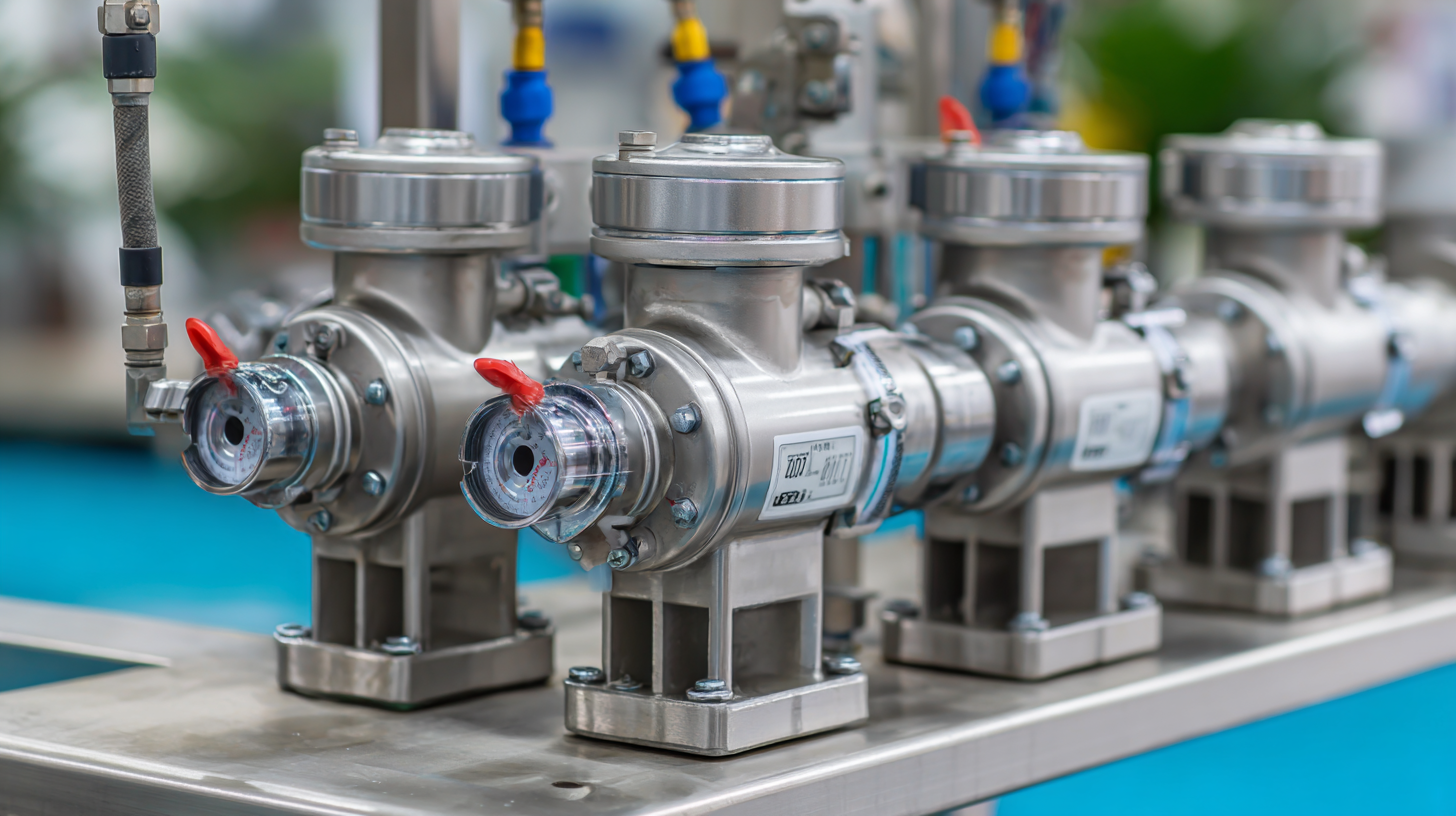

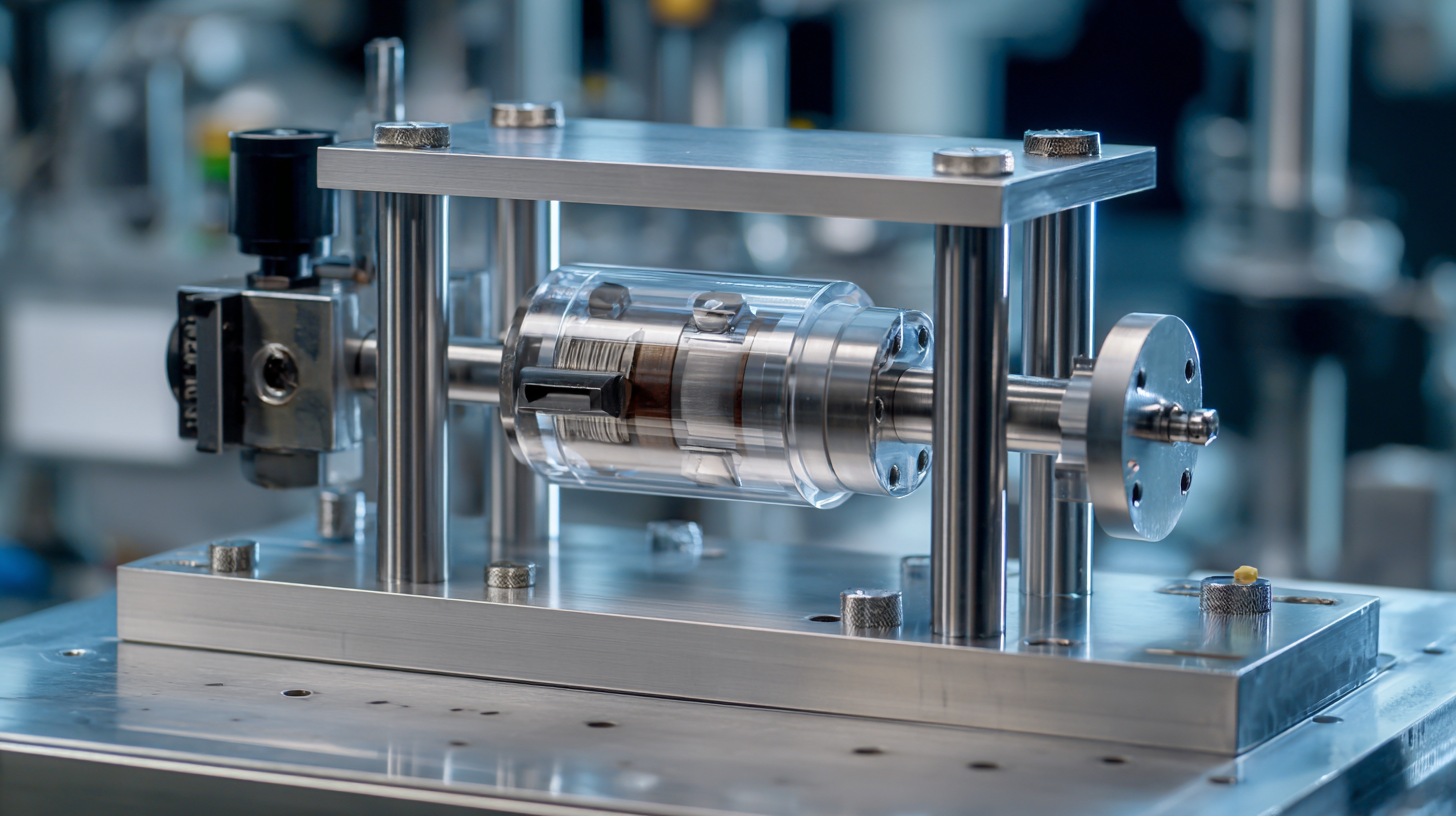

Metering dosing pumps are essential tools across various industries, providing precise control over the flow of chemicals and other fluids. These pumps operate on the principle of positive displacement, ensuring steady-state accuracy that is crucial for applications requiring exact dosages. Understanding the core functionalities of metering dosing pumps allows users to select the right pump for their specific needs, taking into consideration factors like repeatability and linearity, which play significant roles in maintaining accuracy throughout the dosing process.

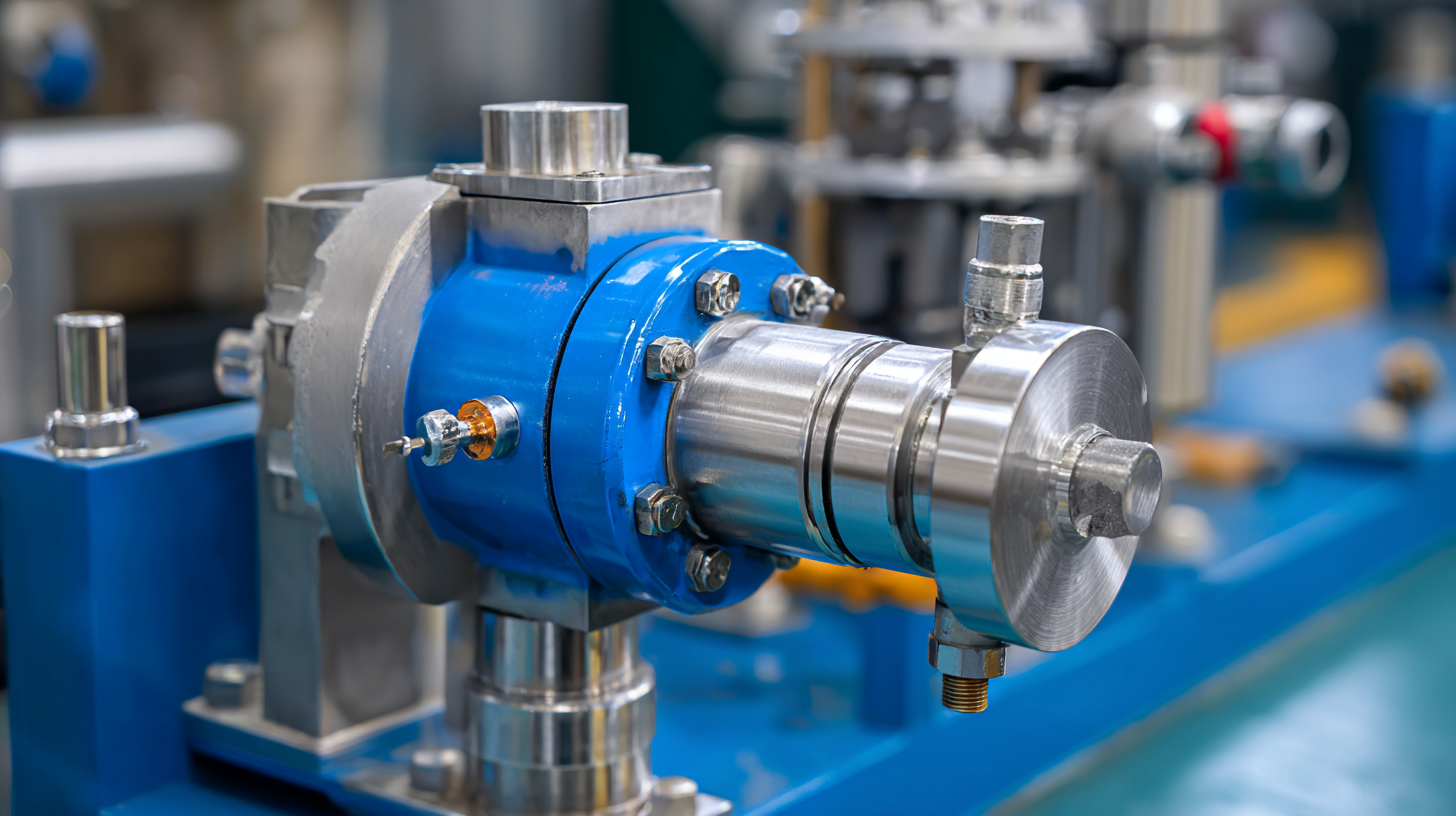

Recent advancements in metering pump technology have enhanced their efficiency and reliability, making them more accessible for various applications. For instance, the latest innovations in chemical metering pumps offer improved performance, catering to the demands of industries that require consistent and controlled feeding of chemicals. Additionally, online learning modules have emerged, providing comprehensive knowledge about positive displacement pumping technologies. This educational resource can be invaluable for professionals looking to deepen their understanding of metering dosing pumps and maximize their applications effectively.

When choosing a metering dosing pump, it’s essential to focus on several key features that define high-quality performance. One of the most critical aspects is precision; a reliable metering pump should consistently deliver accurate dosages, even at small volumes, to ensure process integrity. Look for pumps that incorporate advanced technologies that allow for precise microliter dispensing. This level of accuracy is particularly important in applications where small variations can have significant impacts on overall outcomes.

Another vital feature to consider is the pump's adaptability to various chemicals and flow rates. A versatile metering dosing pump should be capable of handling different fluids, including corrosive and viscous substances, without compromising performance. Additionally, durability and ease of maintenance are essential; operators should be able to service the equipment with minimal downtime. With the metering pumps market projected to reach USD 8.5 billion by 2028, investing in high-quality technology not only enhances operational efficiency but also supports sustainable growth for businesses across industries.

When it comes to metering dosing pumps, the choice between domestic and imported models can be crucial for both efficacy and reliability in various applications. Domestic metering dosing pumps often emphasize affordability and localized service support, which can be advantageous for businesses looking to minimize downtime and ensure faster maintenance. These pumps may also be designed with the specific needs of the local market in mind, potentially offering features that align more closely with regional standards and regulations.

On the other hand, imported metering dosing pumps often boast advanced technology and innovative features that can provide enhanced precision and efficiency. They tend to undergo rigorous testing in various industries, offering a proven track record of performance. However, the initial investment may be higher, and users should consider the long-term benefits against the upfront costs. Additionally, understanding the support infrastructure available for these imported models is crucial, as accessibility to spare parts and technical assistance can significantly influence overall operational efficiency.

Ultimately, the choice between domestic and imported metering dosing pumps should be guided by specific operational requirements, budget considerations, and the desired level of technical support, ensuring the selected pump aligns with the user’s unique needs and application contexts.

| Feature | Domestic Metering Dosing Pump | Imported Metering Dosing Pump |

|---|---|---|

| Price Range | $150 - $500 | $300 - $1,000 |

| Flow Rate | 0.5 - 20 L/h | 1 - 30 L/h |

| Accuracy | ±2% of full scale | ±1% of full scale |

| Power Supply | 220V AC | 110V/220V AC |

| Maintenance Frequency | Every 6 months | Once a year |

| Key Applications | Water treatment, chemical processing | Pharmaceuticals, food processing |

When it comes to metering dosing pumps, selecting the right manufacturer significantly impacts quality and performance. Chinese factories have emerged as pivotal players in the global market, often noted for their ability to deliver high-quality products at competitive prices. According to a recent industry report by MarketsandMarkets, the Asia-Pacific region, led by China, is projected to dominate the metering pump market, with a growth rate of over 6% from 2021 to 2026. This growth can be attributed to technological advancements and the increasing demand for automated systems in various industries such as water treatment, pharmaceuticals, and food processing.

What sets Chinese manufacturers apart is their commitment to innovation and efficiency. Many companies have adopted advanced manufacturing techniques and quality control measures that meet international standards. A study from Research and Markets highlights that over 70% of Chinese metering pump manufacturers have implemented ISO 9001 certification, ensuring a consistent level of quality and reliability in their products. Additionally, the presence of cost-effective labor and materials enables these factories to offer tailored solutions that meet specific client needs, making them an attractive option for businesses worldwide. When choosing a supplier, understanding these factors can help ensure optimal performance and reliability in your dosing applications.

When it comes to maintaining the longevity of your metering dosing pump, regular maintenance is essential. First, it’s crucial to keep the pump clean and free of debris. Routine inspections to check for any blockages or wear in the intake and discharge lines can prevent potential failures. Additionally, maintaining proper fluid levels and ensuring that the valves are not clogged will help the pump operate smoothly and efficiently.

Another important aspect of pump maintenance is monitoring its performance. Keep an eye on the pump’s flow rate and pressure to identify any deviations from normal operation. If you notice irregularities, it's advisable to recalibrate the pump or replace parts as necessary. Moreover, lubricating moving parts according to the manufacturer’s guidelines can reduce friction and prolong the life of the pump. By following these simple yet effective maintenance tips, you can ensure that your metering dosing pump remains reliable and efficient for years to come.