In today's competitive landscape, businesses in various industries are increasingly recognizing the critical role of precision in their operations. A recent report by MarketsandMarkets indicates that the global market for micro dosing pumps is expected to reach $1.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.5%. This surge highlights the importance of efficiency and accuracy in fluid dispensing processes, which can significantly impact productivity and overall success.

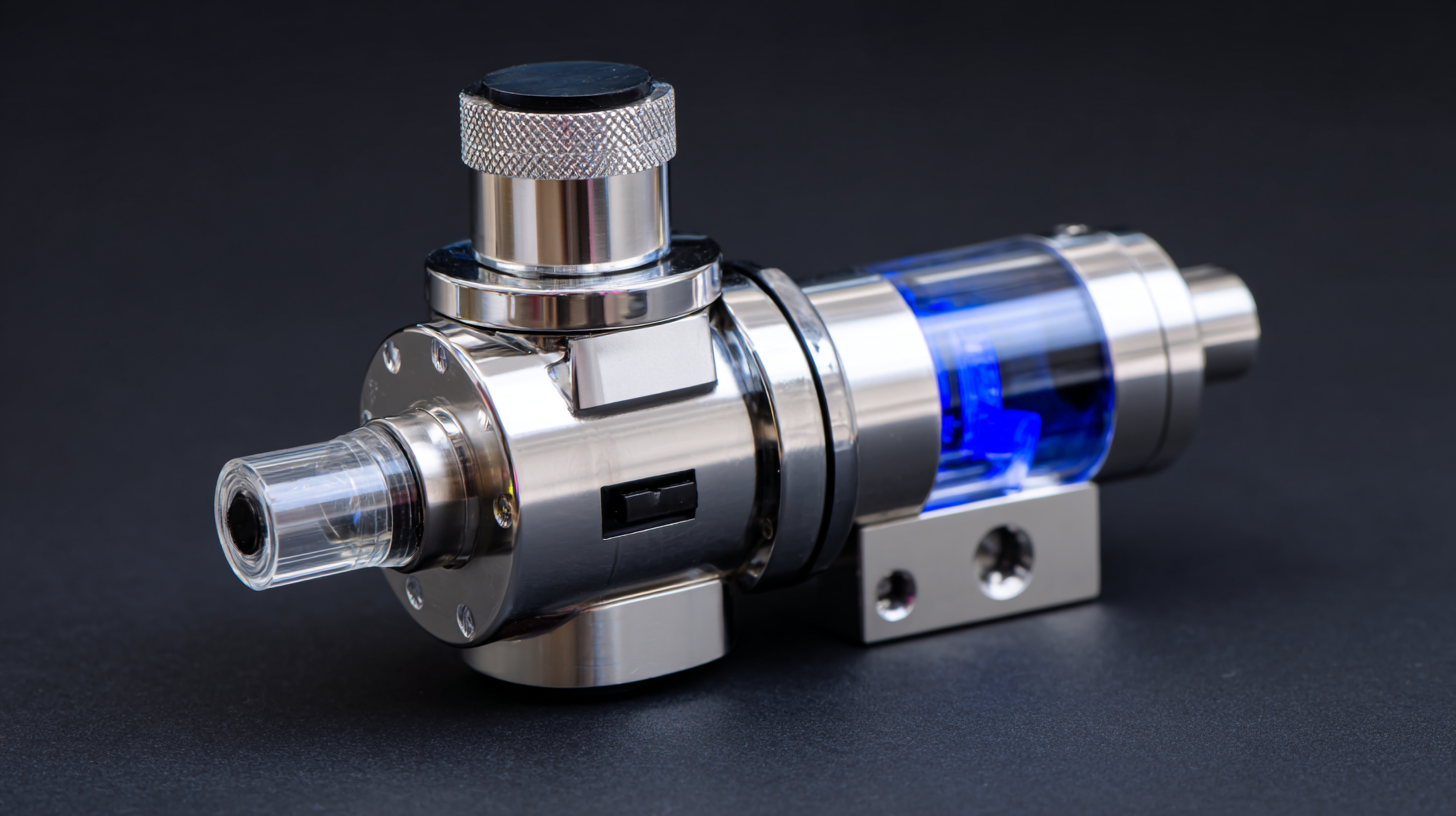

Micro dosing pumps are essential tools that enable businesses to achieve optimal dosing accuracy while minimizing waste and operational costs. By leveraging the advantages offered by micro dosing pumps, companies can enhance their operational efficiency, ensure product consistency, and improve customer satisfaction, ultimately driving long-term success in their respective markets.

In today’s competitive market, precision in microdosing solutions is not just a luxury; it is a necessity. Businesses across various industries, from pharmaceuticals to food and beverage, require exact measurements to ensure product quality and compliance with regulatory standards. A micro dosing pump that delivers accurate and consistent dosages minimizes waste and maximizes efficiency. This precision is critical not only for maintaining product integrity but also for enhancing customer satisfaction, as it ensures that the end user receives exactly what they expect.

Moreover, the importance of precision extends beyond just the immediate product output. It impacts broader aspects like inventory management and cost control. By using the best micro dosing pump, companies can fine-tune their operations, reducing variability and streamlining processes. This leads to significant cost savings over time, as less product is wasted and rework due to inaccuracies is minimized. Thus, investing in a high-quality micro dosing pump is essential for businesses aiming for long-term success, as it empowers them to deliver top-notch products while optimizing their operational resources.

Micro dosing pumps are rapidly becoming a cornerstone in enhancing operational efficiency across various industries, particularly as businesses strive for sustainability and optimization. These advanced pumps ensure precise and consistent dosing of fluids, which is essential when integrating renewable energy sources like solar and wind into microgrids and smart grids. By accurately managing fluid delivery, micro dosing pumps facilitate the effective use of renewable resources, thus promoting a more efficient and sustainable energy model.

Further, as businesses navigate the complexities of deregulated power systems, the importance of micro dosing pumps becomes even clearer. They support the seamless integration of hybrid renewable energy systems, addressing challenges associated with fluctuating energy outputs. By maintaining optimal operational levels, these pumps not only help businesses capitalize on renewable energy opportunities but also significantly reduce waste and enhance overall productivity. This technological advancement is critical for any business aiming to thrive in today’s competitive and environmentally-conscious market.

| Reason | Description | Impact on Efficiency | Cost Savings |

|---|---|---|---|

| Precision | Ensures accurate dosing of liquids to minimize waste. | Enhances product quality and consistency. | Reduces material costs by up to 20%. |

| Automation | Automates the dosing process, reducing manual labor. | Improves workflow efficiency and speed. | Lowers operational costs by decreasing labor hours. |

| Flexibility | Allows for easy adjustments in dosing rates. | Supports diverse product formulations. | Minimizes changeover costs between products. |

| Reliability | Durable design ensures consistent operation over time. | Reduces downtime and maintenance needs. | Saves costs related to repairs and production delays. |

| Safety | Minimizes risk of spills and leaks during operation. | Enhances workplace safety and compliance. | Lowers insurance and liability costs. |

| Environmental Impact | Decreases waste and energy consumption. | Promotes sustainable practices in operations. | Potentially reduces environmental compliance costs. |

| Scalability | Easily integrates with systems as production demands grow. | Supports continued growth and expansion. | Avoids costly upgrades in the future. |

Traditional dosing methods often face challenges that can impede operational efficiency and accuracy in various industries. Inconsistent dosing can lead to product quality issues, resulting in wasted resources and potential regulatory penalties. Manual techniques are prone to human error, which not only affects the reliability of the dosing process but can also compromise safety standards. As businesses strive for greater precision and efficiency, these outdated methods can be significant roadblocks to success.

The advent of the best micro dosing pumps provides an innovative solution to these persistent issues. By delivering precise amounts of liquids, these pumps minimize waste and ensure uniformity in production processes. Additionally, they can be easily integrated into existing systems, offering flexibility and scalability for growing businesses. With advancements in technology, micro dosing pumps also offer enhanced control over dosing parameters, allowing businesses to respond swiftly to changing demands. Embracing this modern approach not only resolves the challenges associated with traditional methods but also positions companies for sustainable growth and improved competitive advantage.

In today's competitive market, maximizing profitability is imperative, and effective dosing technologies play a crucial role in achieving this goal. By investing in the best micro dosing pumps, businesses can ensure accurate and consistent dispensing of materials, minimizing waste and enhancing product quality. This not only leads to cost savings but also increases customer satisfaction, driving repeat business and referrals.

One key tip for businesses is to regularly calibrate and maintain dosing equipment. This practice ensures that pumps operate at peak efficiency, reducing the risk of inaccurate doses that can lead to costly errors. Additionally, training staff on the proper usage of dosing technologies can further optimize performance and reduce downtime.

Another important aspect is integrating automation into dosing processes. Automated micro dosing pumps can significantly streamline operations, allowing for precise adjustments based on real-time feedback. This ensures that businesses can adapt to changing demands quickly, making them more responsive to market needs while keeping operational costs in check.

In today's competitive market, precise delivery systems are pivotal in elevating customer satisfaction. A recent report from MarketsandMarkets highlights that the global market for micro dosing pumps is expected to grow from $2.59 billion in 2022 to $3.75 billion by 2027, reflecting an annual growth rate of 7.6%. This increasing demand underscores the necessity for businesses to adopt advanced micro dosing pumps, which offer unparalleled accuracy in the delivery of fluids. By delivering exact amounts every time, these pumps help reduce waste and ensure that customers receive the quality they expect.

Furthermore, a study published by the International Journal of Quality & Reliability Management suggests that companies utilizing accurate dosing systems can improve their customer retention rates by up to 20%. This is particularly crucial in industries such as pharmaceuticals and cosmetics, where dosage precision directly impacts product safety and efficacy. Hence, investing in the best micro dosing pump not only enhances operational efficiency but also significantly boosts customer confidence and satisfaction, ultimately driving business success.