The demand for precision in liquid handling has risen significantly in various industries. According to a recent report from the Liquid Handling Association, the global micro dosing pump market is expected to grow by 5.7% annually. This growth reflects the need for accurate dosing in sectors such as pharmaceuticals, food and beverage, and agriculture.

Experts like Dr. Jane Turner, a senior researcher in fluid dynamics, emphasize the importance of these tools. She states, "Micro dosing pumps are crucial for achieving precision in intricate processes.” These devices allow users to dispense very small volumes with high accuracy, minimizing waste and enhancing product quality.

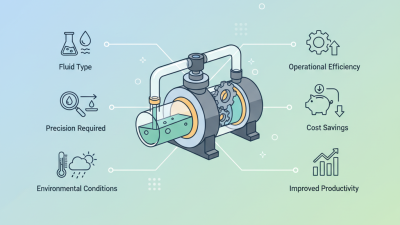

However, not all micro dosing pumps are created equal. Users often face challenges in selecting the right model based on their specific applications. Some pumps may lack the calibration accuracy required, leading to potential inconsistencies in results. Consumers must reflect on their actual needs and consider the pump’s specifications before making a decision.

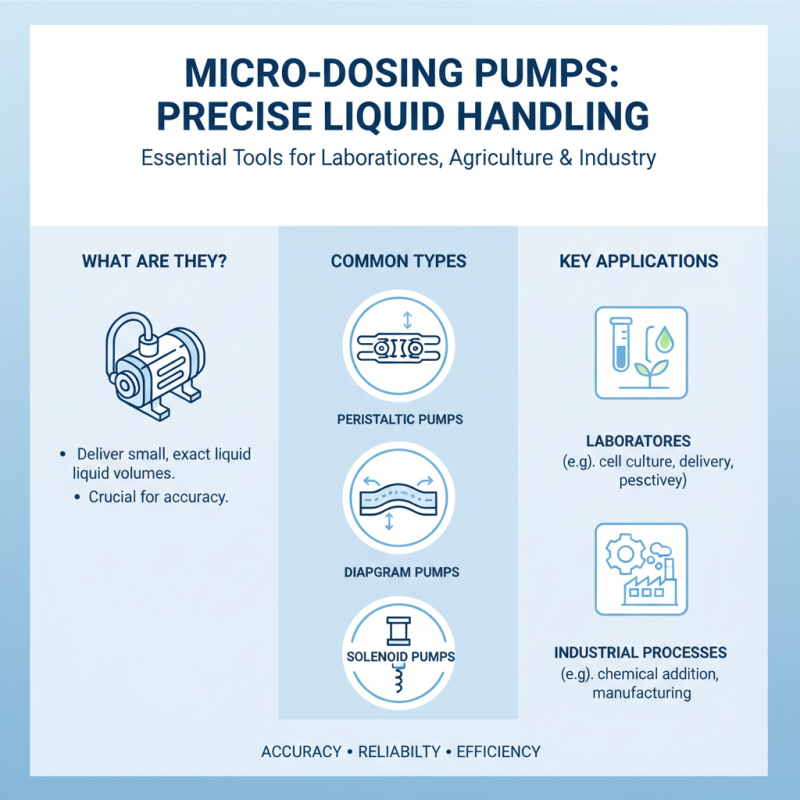

Micro dosing pumps are essential tools for tasks requiring precise liquid handling. They serve various applications in laboratories, agriculture, and industrial settings. The main types include peristaltic pumps, diaphragm pumps, and solenoid pumps. Each type features unique mechanisms that allow for accurate liquid delivery.

Peristaltic pumps are popular for gentle operations. They use rollers to squeeze a tube, ensuring a consistent flow rate. Diaphragm pumps, on the other hand, utilize flexible membranes. They are great for handling aggressive liquids, but they can be less accurate than peristaltic pumps. Solenoid pumps are known for their fast response time, making them effective for quick dosing tasks.

**Tips:** Always calibrate your pump regularly. Small errors can multiply over time, leading to significant inaccuracies. Consider your liquid’s viscosity when selecting a pump type. A thick liquid may require a stronger pump. Ensure maintenance is performed regularly to avoid unexpected failures. Adjustments can be necessary based on the specific application and environment.

When choosing a micro dosing pump, precision is key. Look for pumps with adjustable flow rates. This feature allows you to tailor the dosage to your specific needs. An intuitive interface is also vital. You want an easy way to set and monitor your dosage. Compact size matters too. A smaller pump can fit in tight spaces.

Another important consideration is the material compatibility. Ensure the pump can handle the liquids you plan to use. Some materials might corrode or degrade, causing potential issues. Regular maintenance is crucial as well. Pumps can wear out over time, affecting performance. A model that’s easy to clean will save you headache.

Keep in mind the power source too. Some pumps are electric, while others are manual. Each has its pros and cons. Reliability is paramount. A failed pump can disrupt your workflow. While features are important, always read user reviews. This can give insight into potential issues not mentioned in brochures.

Micro dosing pumps are essential in various industries for precise liquid handling. In pharmaceuticals, accuracy is critical. A study found that 65% of dosing errors occur during manual processes. Micro dosing pumps can reduce this error. They deliver small volumes with high precision, ensuring better drug formulation and patient safety. With the global pharmaceutical market expected to reach $1.5 trillion by 2023, the demand for reliable dosing systems will only grow.

In the food and beverage industry, these pumps handle flavoring and additives. According to industry reports, precise dosing increases product consistency. In an average production line, even slight variations can lead to significant quality issues. A micro dosing pump can help maintain uniform standards. This is crucial as 76% of consumers report brand loyalty influenced by taste consistency. However, the initial investment in these pumps can be high. Businesses must weigh costs versus benefits.

Environmental applications also benefit from micro dosing technology. They play a role in water treatment processes, managing chemicals like chlorine. A well-calibrated dosing pump can enhance treatment efficiency. Some reports indicate that inaccurate dosing can cause up to 30% of waste in chemical usage. The challenge lies in integrating these systems seamlessly into existing setups. Adapting to new technology requires careful planning and staff training.

| Industry | Application | Flow Rate (mL/min) | Accuracy (%) | Features |

|---|---|---|---|---|

| Pharmaceutical | Injection Preparation | 0.1 - 50 | ±1 | High precision, sterile handling |

| Food & Beverage | Flavoring Addition | 0.5 - 100 | ±2 | Corrosion-resistant, easy cleaning |

| Chemical | Additive Dosing | 1 - 300 | ±1.5 | Variable speed control, rugged design |

| Water Treatment | Chemical Injection | 0.1 - 200 | ±1 | Automated control, API integration |

| Cosmetics | Perfume Mixing | 0.2 - 20 | ±3 | Gentle handling, minimal shear stress |

Micro dosing pumps are essential for precise liquid handling in various applications. Choosing the right one can be challenging due to the many options available. Popular brands often differ in accuracy, ease of use, and maintenance requirements. Some may struggle with calibration. It’s important to assess your specific needs before choosing.

When comparing models, consider the flow rate and dosage accuracy. Some pumps excel at delivering consistent amounts. Others may vary slightly, impacting your results. Look for user reviews. They often reveal real-world performance issues that specifications might not cover.

Tips: Always test a new pump with water before using it with other liquids. This helps identify any inconsistencies. Be prepared to adjust settings according to your application. Routine maintenance can extend pump life, ensuring reliable operation over time. Reflect on which features genuinely matter for your work, as not all functionalities may be necessary.

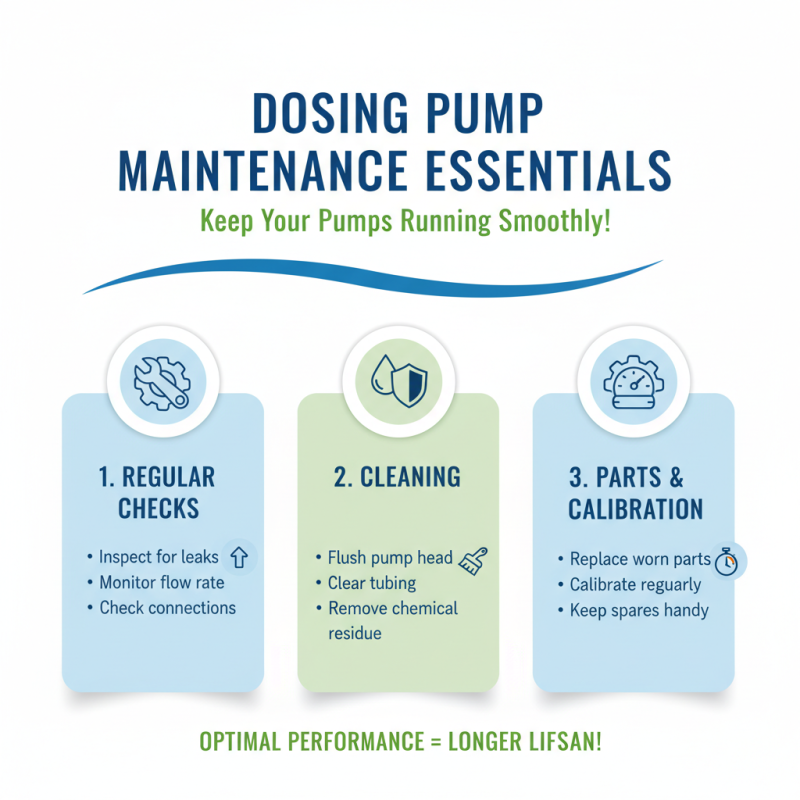

When it comes to dosing pumps, maintenance is crucial for optimal performance. Regular checks can prevent potential issues. Here are some key tips.

Clean the pump regularly. Residue buildup can affect accuracy. Use appropriate cleaning agents that won’t damage the pump materials. Inspect all connections routinely. Loose or damaged fittings can introduce air bubbles. Air can disrupt the dosing accuracy.

Monitor the fluid levels. Low levels can lead to pump running dry, causing damage. Schedule replacement for worn parts. Don’t wait until they fail. Check the pump's calibration frequently. Drift can occur unnoticed, affecting performance.

Record all maintenance actions. This helps identify patterns or recurring problems. A log will give you insights into the pump’s reliability. It’s okay to find imperfections; every pump has limits. Reflect on past errors to improve future maintenance practices.