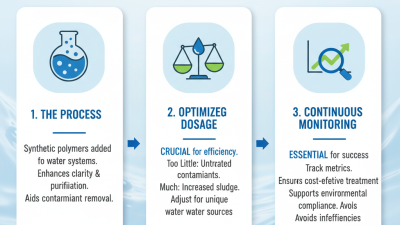

Polymer Dosing plays a crucial role in modern water treatment processes. This area of technology has become essential for improving water quality efficiently. Experts like Dr. Emily Carter, a renowned figure in water treatment, say, "Effective Polymer Dosing can significantly enhance our water purification efforts."

In the quest for better water treatment solutions, choosing the right polymer dosing system is vital. With numerous options available, evaluating efficiency and effectiveness is key. Proper dosing is critical, yet it remains challenging for many facilities. Oftentimes, users overlook how slightly adjusting the dosage can lead to vastly different outcomes.

Exploring the best systems reveals innovation and room for improvement. While some systems perform well, others may need further refinement. A great polymer dosing system should balance cost and performance amid varying conditions. Adequate training and understanding of polymer properties remain essential for everyone involved in water treatment. Emphasizing these aspects can improve outcomes and ensure better water for all.

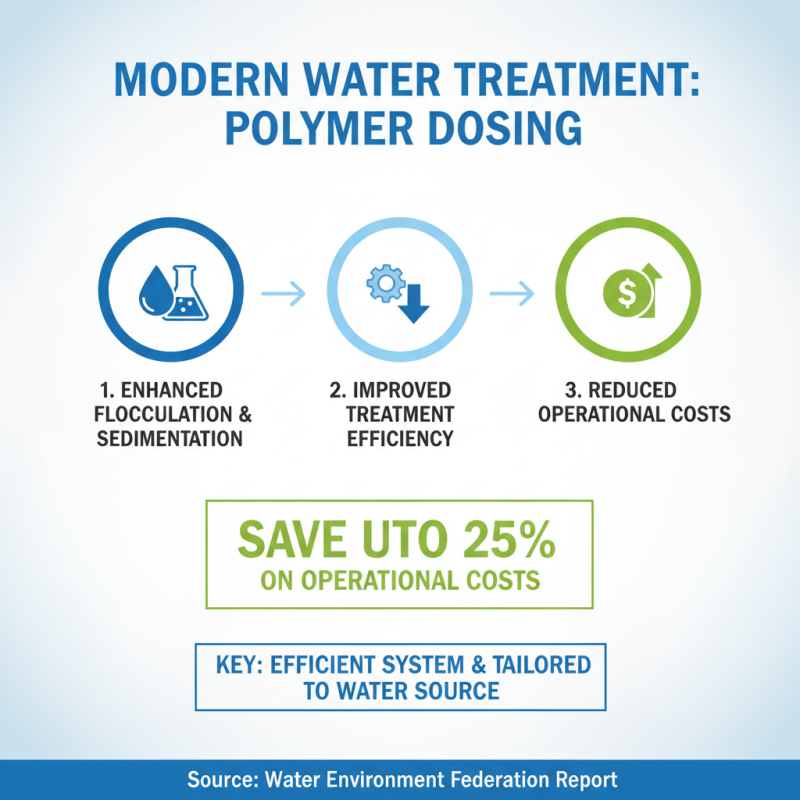

In modern water treatment processes, polymer dosing systems play a vital role. These systems enhance flocculation and sedimentation, improving overall treatment efficiency. According to a report by the Water Environment Federation, the proper use of polymer dosing can reduce operational costs by up to 25%. This potential savings highlights the value of selecting an efficient system tailored to specific water sources.

Polymer dosing systems utilize various methods to deliver the correct amount of polymer. Accurate metering reduces waste and maximizes performance. Inaccuracies in dosing can lead to under-treatment or excessive costs. Operators must regularly calibrate dosing equipment. Frequent checks prevent inefficiencies.

Tips: Monitor dosages closely. Small adjustments can yield big results. Periodic training for staff on system operation ensures they are well-informed. Regular maintenance of equipment prevents breakdowns, which can cause costly downtime. Implementing a feedback loop can help refine processes over time.

When selecting a polymer dosing system for water treatment, several key features deserve attention. Accuracy in dosing is crucial. Systems should provide precise measurements of the polymer. This ensures optimal performance in coagulation and flocculation processes. A system that lacks precision can lead to inefficiency. It might result in polymer overdosing or underdosing, affecting treatment quality.

Another important aspect is the ease of maintenance. A polymer dosing system should be user-friendly. This means easy access to components for cleaning and repairs. Complicated systems can lead to downtime. Regular maintenance needs to be manageable so that operators can act quickly. It’s vital to consider the durability of materials used, too. Systems often face harsh environments. Corrosion resistance becomes essential in these cases, prolonging the system's lifespan.

Finally, flexibility in operation is something to evaluate. A system should adapt to changes in water quality and flow rates. Rigid systems fail to cope with varying treatment needs efficiently. Users may need to reflect on scalability as well. If future expansions are planned, ensure that the dosing system can accommodate growth without major overhauls. These factors collectively enhance water treatment efficiency, yet many users overlook them.

In the realm of water treatment, polymer dosing systems play a crucial role. These systems ensure effective flocculation, enhancing the removal of suspended solids. When selecting a system, consider factors like efficiency, reliability, and user-friendliness. Some systems may require complex maintenance. It’s important to assess their long-term usability.

Efficiency can vary significantly between different designs. Some systems work perfectly in ideal conditions but struggle under varying water qualities. This inconsistency can lead to frustration and unforeseen costs. It's vital to understand the specific needs of your water treatment process, as not every system suits every application.

Moreover, environmental impact should not be overlooked. Some polymer dosing systems may generate waste or by-products. Regular evaluation of their performance is essential. Create a feedback loop to address any inefficiencies quickly. Understanding these factors can make a significant difference in overall operational efficiency.

When optimizing water treatment, polymer dosing systems play a crucial role. An effective system can enhance the flocculation process and improve overall efficiency. Recent studies indicate that systems with automated controls can reduce polymer consumption by up to 30%. Meanwhile, the operational costs can fluctuate based on the dosing accuracy and maintenance needs.

A detailed analysis of various systems reveals a significant variance in pricing. Some entry-level models can be acquired for less than $3,000, yet they may lack durability. Conversely, high-performance systems can exceed $10,000, providing reliable long-term operation. It’s essential to balance cost and performance when selecting a system.

Tip: Regular maintenance is vital to ensure optimal performance. Neglecting service can lead to increased polymer usage and costs.

Additionally, while many systems claim high efficiency, some user reviews suggest that the actual performance may not meet expectations. It's crucial to conduct a thorough assessment before making a purchase decision. Always consider operational flexibility and ease of integration with existing systems.

Tip: Monitor your system's performance continually. Early detection of issues can save time and resources.

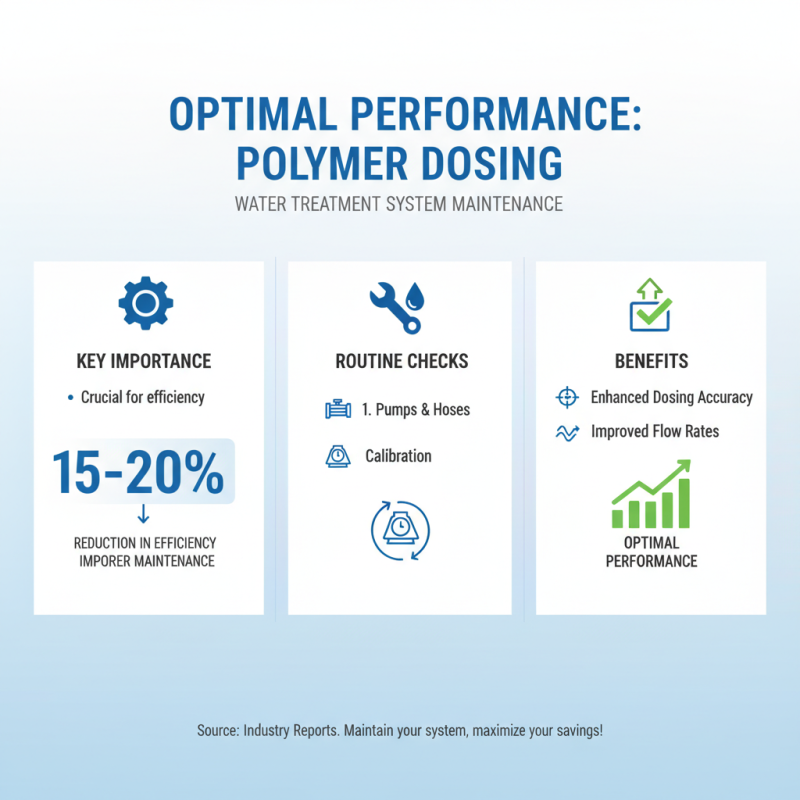

Proper maintenance of polymer dosing systems is crucial for optimal performance in water treatment. Regular checks and calibration can enhance dosing accuracy. According to industry reports, improper maintenance can lead to a 15-20% reduction in polymer efficiency. This underscores the need for routine inspection of pumps and hoses. Issues like buildup or wear can significantly hamper flow rates.

Operators often overlook the importance of maintaining a clean environment around the dosing system. Dust and debris can enter the system, compromising polymer quality. It's vital to schedule cleaning sessions. Monitoring the viscosity of stock solutions is also critical. Studies show that maintaining viscosity within recommended levels can improve system reliability. Many facilities fail to maintain these checks, leading to inefficiencies.

Best practices for usage involve training staff on the specifics of each system. Miscommunication about dosing rates can result in significant overdosing or underdosing. Such practices are wasteful and costly. Implementing a checklist for daily operations can mitigate these risks. Continuous education on polymer chemistry may reduce errors in application, enhancing overall plant efficiency.