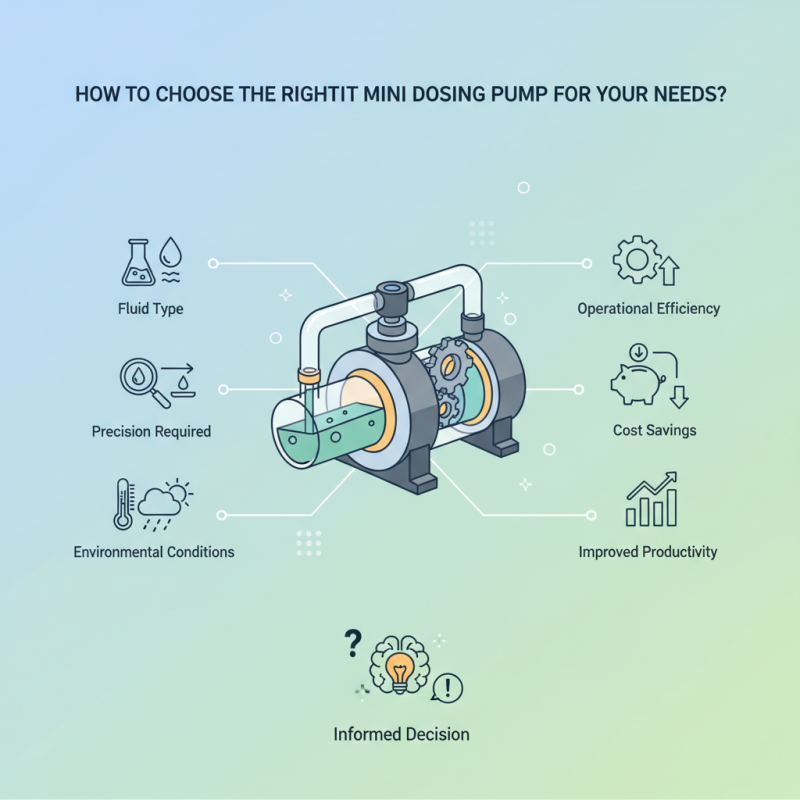

In the ever-evolving world of fluid management, selecting the right "Mini Dosing Pump" can significantly impact operational efficiency and performance. Dr. Emily Carter, a leading expert in dosing technology, emphasizes the importance of this decision: "Choosing the right mini dosing pump is not just about performance; it's about understanding your specific application needs." With a myriad of options available, from different materials to various flow rates, the selection process can be daunting.

When evaluating your options, it's crucial to consider factors such as the type of fluid being pumped, the required precision, and environmental conditions. A well-chosen Mini Dosing Pump can enhance accuracy and reduce waste, ultimately leading to cost savings and improved productivity. As industries increasingly seek to optimize their processes, understanding the nuances of these essential tools becomes imperative for success.

In this guide, we aim to demystify the selection process, providing insights into the key considerations and features to look for when investing in a Mini Dosing Pump. Empowered with the right knowledge and expert advice, you can make an informed decision that aligns with your operational goals.

Mini dosing pumps are increasingly recognized for their versatility across various industries, from pharmaceuticals to water treatment. These pumps are designed for precise and controlled dispensing of liquids in small volumes, making them essential in applications that require accuracy, such as chemical dosing, nutrient delivery in agriculture, or precise liquid formulation in laboratories. According to a report by Markets and Markets, the mini dosing pump market is projected to reach USD 1.5 billion by 2025, highlighting their growing significance.

When selecting a mini dosing pump, it is crucial to understand its applications. For instance, in the pharmaceutical industry, where stringent regulations govern the dispensing of solvents, mini dosing pumps offer metered and consistent delivery, thereby enhancing product quality and compliance. In agriculture, these pumps have proven invaluable in precise fertilization, which can improve crop yields while minimizing environmental impact. Additionally, various industrial sectors rely on mini dosing pumps to maintain consistent quality in manufacturing processes.

Tips:

When selecting a mini dosing pump, several key factors should be considered to ensure it suits your specific applications. The first aspect to evaluate is the pump's capacity and flow rate. Depending on your needs, you'll want a pump that can deliver the right amount of fluid consistently. Assess the volume of liquid to be dispensed and the required dosing frequency in your process. Ensuring the pump can handle these specifications will improve efficiency and performance.

Another critical factor is the materials used in the pump's construction. Different applications may involve various chemicals and substances, meaning that the pump must be compatible with the fluids being handled. Look for pumps made with materials that resist corrosion and wear, which will not only extend the pump's lifespan but also prevent contamination of the products being dosed. Additionally, consider the ease of maintenance and the availability of replacement parts to minimize downtime and ensure smooth operations over time.

When selecting a mini dosing pump, it's crucial to understand the various types available and their specific applications. Mini dosing pumps can generally be categorized into several types, including diaphragm pumps, peristaltic pumps, and gear pumps. Diaphragm pumps are often favored for their accuracy and ability to handle corrosive fluids, making them ideal for chemical dosing in industries such as water treatment and pharmaceuticals. According to a report by ResearchAndMarkets, the global market for diaphragm dosing pumps is expected to grow by approximately 6.5% annually, owing to the increasing demand for precise fluid control in various sectors.

Peristaltic pumps, on the other hand, utilize a flexible tube and rotating rollers, which compress and release the tube to transport fluids. This design minimizes contamination, an essential feature in food processing and biotechnology applications. The International Journal of Food Engineering highlights that the demand for peristaltic dosing pumps in food and beverage applications has surged, driven by tighter regulatory requirements and a focus on hygiene.

Gear pumps, while less common, provide reliable dosing for viscous fluids and are often utilized in industries like oil and gas. A recent market analysis indicates that gear pumps account for approximately 10% of the mini dosing pump market, driven by their ability to handle thicker substances efficiently. By understanding these different types of mini dosing pumps and their specific uses, you can make an informed choice to meet your dosing needs effectively.

| Type of Mini Dosing Pump | Flow Rate (L/H) | Pressure Range (Bar) | Common Applications |

|---|---|---|---|

| Diaphragm Pump | 0.5 - 20 | 0 - 10 | Water treatment, chemicals dosing |

| Peristaltic Pump | 1 - 15 | 0 - 3 | Food processing, laboratory applications |

| Electronic Metering Pump | 0.1 - 10 | 0 - 8 | Water treatment, agricultural applications |

| Solenoid Pump | 0.5 - 4 | 0 - 5 | Pool maintenance, industrial dosing |

| Gear Pump | 0.1 - 3 | 0 - 15 | Viscous fluids, lubricants |

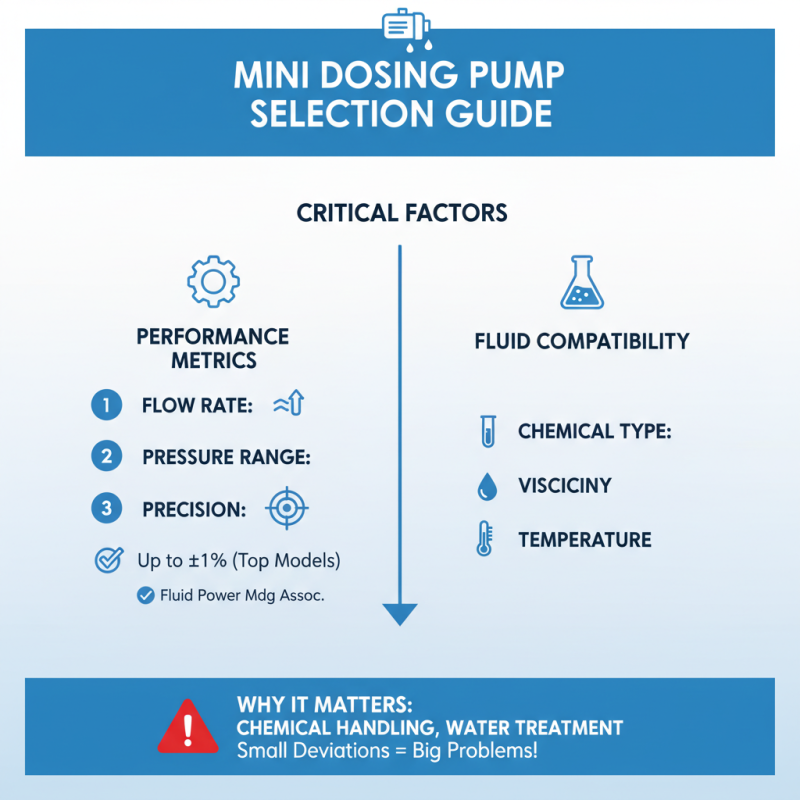

When selecting a mini dosing pump, evaluating its performance and compatibility with the fluids you intend to use is critical. Pumps are typically assessed on several key performance metrics, including flow rate, pressure range, and precision. According to a recent industry report from the Fluid Power Manufacturers Association, the accuracy of a dosing pump can vary significantly, with top-performing models achieving dosing precisions as high as ±1% of the set flow rate. Such precision is essential in applications like chemical handling and water treatment, where even minor deviations can lead to significant negative outcomes.

Additionally, compatibility with various fluids must be thoroughly examined. Different materials used in pump construction can affect a pump's performance with various chemicals, such as acids, bases, and solvents. For instance, a survey from the Chemical Engineering Journal indicates that over 60% of pump failures in chemical processes are linked to material incompatibility. Thus, it is essential to match the pump materials with the properties of the fluids, considering factors such as viscosity, temperature, and corrosiveness. Conducting a compatibility analysis helps ensure that the pump maintains its integrity over time, ultimately leading to more reliable operation and reduced maintenance costs.

When selecting a mini dosing pump, budget considerations play a crucial role in ensuring that you find a cost-effective solution that meets your needs. Dosing pumps can vary significantly in price based on their specifications, features, and capabilities. It's essential to determine your budget early in the process, allowing you to narrow down your options and focus on models that offer the best value. Assessing your specific requirements, such as flow rate, precision, and ease of use, will help you avoid overspending on unnecessary features.

Tips: Start by comparing prices from various suppliers to get an understanding of the market range. Look for user reviews and testimonials to gauge the reliability and performance of the dosing pumps you're considering. Sometimes, opting for slightly older models can provide significant savings without sacrificing quality or functionality.

Additionally, consider the long-term operational costs associated with the pumps, such as maintenance, power consumption, and replacement parts. A more affordable initial purchase price may not always equate to cost-effectiveness if the ongoing expenses are high. When evaluating options, focus on the total cost of ownership to make a more informed decision.

This chart illustrates the average costs of various types of mini dosing pumps measured in USD. These data points can help guide your budget considerations and identify cost-effective options.