Choosing the right Automatic Dosing System can greatly impact efficiency and accuracy in various industries. According to a report by Technavio, the global automatic dosing system market is expected to grow by 4.5% annually through 2026. This growth highlights the increasing reliance on automated solutions in sectors like water treatment and pharmaceuticals.

Expert Dr. Emily Carson, a well-known figure in the field, emphasizes, "Selecting an appropriate Automatic Dosing System requires careful consideration of specific operational needs." Despite this knowledge, many decision-makers overlook critical factors like system compatibility and dosing accuracy.

In practice, many users find themselves overwhelmed by the myriad choices. It becomes essential to evaluate not only the features but also the long-term support and maintenance services offered. This choice often defines operational effectiveness, making it crucial to navigate the complexities effectively. Balancing these elements can be challenging, yet it is vital for successful implementation.

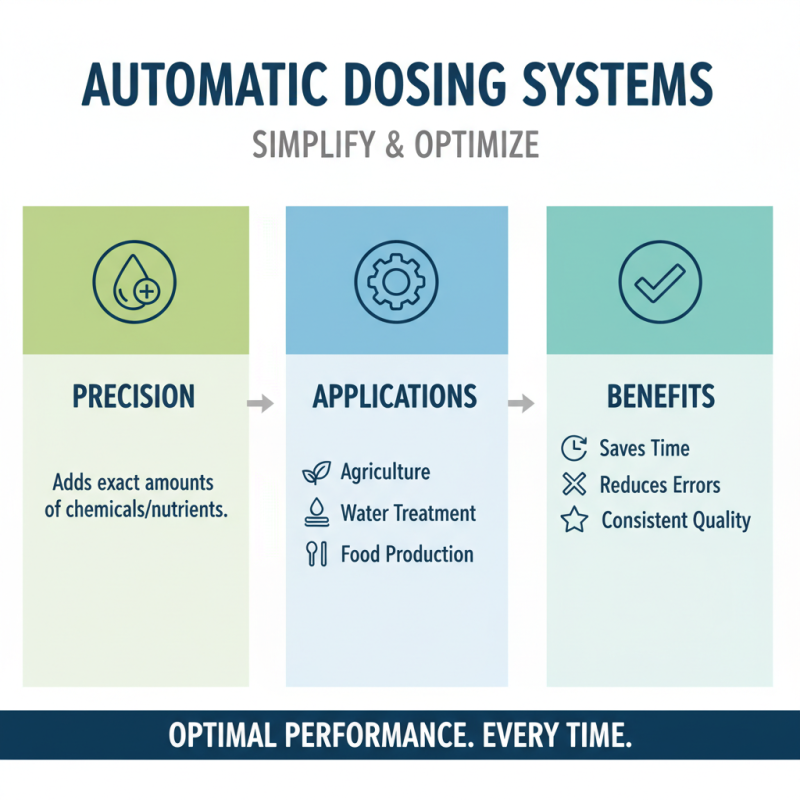

Automatic dosing systems simplify the process of adding precise amounts of chemicals or nutrients to various applications. These systems are beneficial in industries like agriculture, water treatment, and food production. They help maintain consistent product quality. Automated systems save time and reduce errors, ensuring optimal performance.

Understanding their benefits is crucial before choosing one. These systems often come with programmable settings, allowing customization based on specific needs. A well-designed system increases efficiency and minimizes waste. Accurate dosing can lead to better crop yields or cleaner water, which are essential for business success.

However, not all systems fit every application. Some may require more maintenance than expected. Sometimes, users find the settings complicated. This can lead to frustration and suboptimal results. Evaluating the features carefully and considering the learning curve is vital. Investing time upfront can prevent issues later on.

When choosing an automatic dosing system, it’s crucial to assess your specific requirements. Start by identifying the types of substances you will be dosing. Chemicals vary widely in viscosity, density, and safety concerns. You need a system that accommodates your specific materials. Different applications may require different precision levels. Some processes demand tight tolerances, while others can be more lenient.

Consider the scale of your operations. Small laboratories may only need basic dosing capabilities. Larger industrial operations often require advanced features like integration with existing systems. Think about future needs as well. A system that meets your immediate needs might not be suitable for scalability. It's vital to imagine how your operations might evolve.

Don’t forget to evaluate the ease of use. Systems that are overly complex can lead to errors. User-friendly interfaces simplify operations. Regular maintenance and support are also important factors. Reflect on your team's capabilities and training. Inadequate training can lead to misuse, which complicates workflows.

This bar chart compares the accuracy and ease of use rating of different automatic dosing systems. System A shows the highest accuracy, while System D rates the best for ease of use.

Choosing the right automatic dosing system involves evaluating various key features. One important aspect is the dosing accuracy. Systems should provide precise measurements to avoid wastage. You want to ensure the system is reliable in every dose. Inaccurate dosing can lead to serious inefficiencies.

Another critical feature is user-friendliness. A complicated interface can hinder efficient operations. Look for intuitive designs. Systems that are easy to navigate can save time. Time is precious, and a confusing setup is frustrating. It may lead to incorrect usage, which could cause issues.

Finally, consider the system's capacity and compatibility. Different applications require varying capacities. Make sure the system can handle your specific needs. Not all setups fit every situation. A mismatch can lead to operational troubles. Reflect on what you truly need before making a decision.

| Feature | Description | Importance Level |

|---|---|---|

| Calibration Accuracy | The ability to accurately dispense exact amounts of chemicals. | High |

| User Interface | Ease of use and navigation through the system settings. | Medium |

| Maintenance Requirements | Frequency and ease of maintenance procedures. | High |

| Flow Rate | The speed at which the system can dispense chemicals. | High |

| Integration Capabilities | Ability to connect with other systems or equipment. | Medium |

| Safety Features | Built-in mechanisms to prevent accidents and spills. | High |

| Cost | Initial purchase price and ongoing operational costs. | Medium |

When evaluating different types of automatic dosing systems, it’s essential to consider the specific needs of your operation. There are various systems available, each with unique features. Some systems offer precise measurements, while others prioritize ease of use. Customizability matters here, too. If your application changes frequently, look for a system that can adapt to new requirements.

Another factor is the method of delivery. Some systems inject solutions directly, while others need mixing tanks. The size of these systems varies greatly. Larger systems may serve industrial needs, while compact models fit smaller spaces. Think about your available space before making a decision.

Maintenance can be a challenge with automated systems. Regular checks are necessary to ensure accuracy. Some users find routine upkeep burdensome. Mistakes can happen, leading to incorrect dosages. It’s crucial to reflect on how much time you can dedicate to monitoring. Automatic systems may simplify dosing, but they require commitment and care.

When exploring automatic dosing systems, it’s crucial to consider costs and ongoing maintenance. Initial costs can vary widely. Aim for a system that meets your specific needs without overspending. Some options may appear cheap at first glance but come with hidden fees. Assess not only the purchase price but also additional expenses for parts and software updates.

Tip: Always ask for a detailed quote that includes all costs. This can prevent unexpected financial surprises down the road.

Maintenance is another key aspect. Some systems require regular servicing, while others are more user-friendly. Complex systems can lead to longer downtimes during repairs. Think about how much time you can dedicate to maintenance.

Tip: Evaluate how easily you can find replacement parts and service providers. Supplier support is crucial for long-term satisfaction. Consistent assistance can help avoid major disruptions in your operations. Check reviews and feedback from other users regarding supplier reliability.

A little research can go a long way. It’s important to find a balance between cost, maintenance ease, and the quality of supplier support.