In today's industrial landscape, the efficiency and accuracy of chemical dosing are paramount, making the choice of the right Membrane Dosing Pump a critical decision for operational success. According to a recent market research report by Insert reputable source, the global market for dosing pumps is projected to reach $6.3 billion by 2026, reflecting an annual growth rate of over 5%. This trend underscores the increasing reliance on precision dosing solutions in various sectors, including water treatment, pharmaceuticals, and food production. As industries continue to embrace automation and strive for higher efficiency, selecting a Membrane Dosing Pump that aligns with specific operational needs becomes essential to ensure optimal performance, reduce downtime, and comply with stringent regulatory standards. In this blog, we will explore key considerations and expert tips to guide you in making an informed decision tailored to your industrial requirements.

When selecting a membrane dosing pump for industrial applications, it's crucial to understand the various types available on the market, each designed to meet specific operational demands. For instance, progressive cavity dosing pumps are renowned for their efficiency in handling multiphase fluid flow. These pumps can effectively manage varying viscosities and shear conditions, making them ideal for applications involving delicate substances, such as monoclonal antibodies. Recent studies indicate that the shear stress influences protein integrity during low-volume aseptic filling, highlighting the importance of choosing pumps that minimize shear while ensuring accurate dosing.

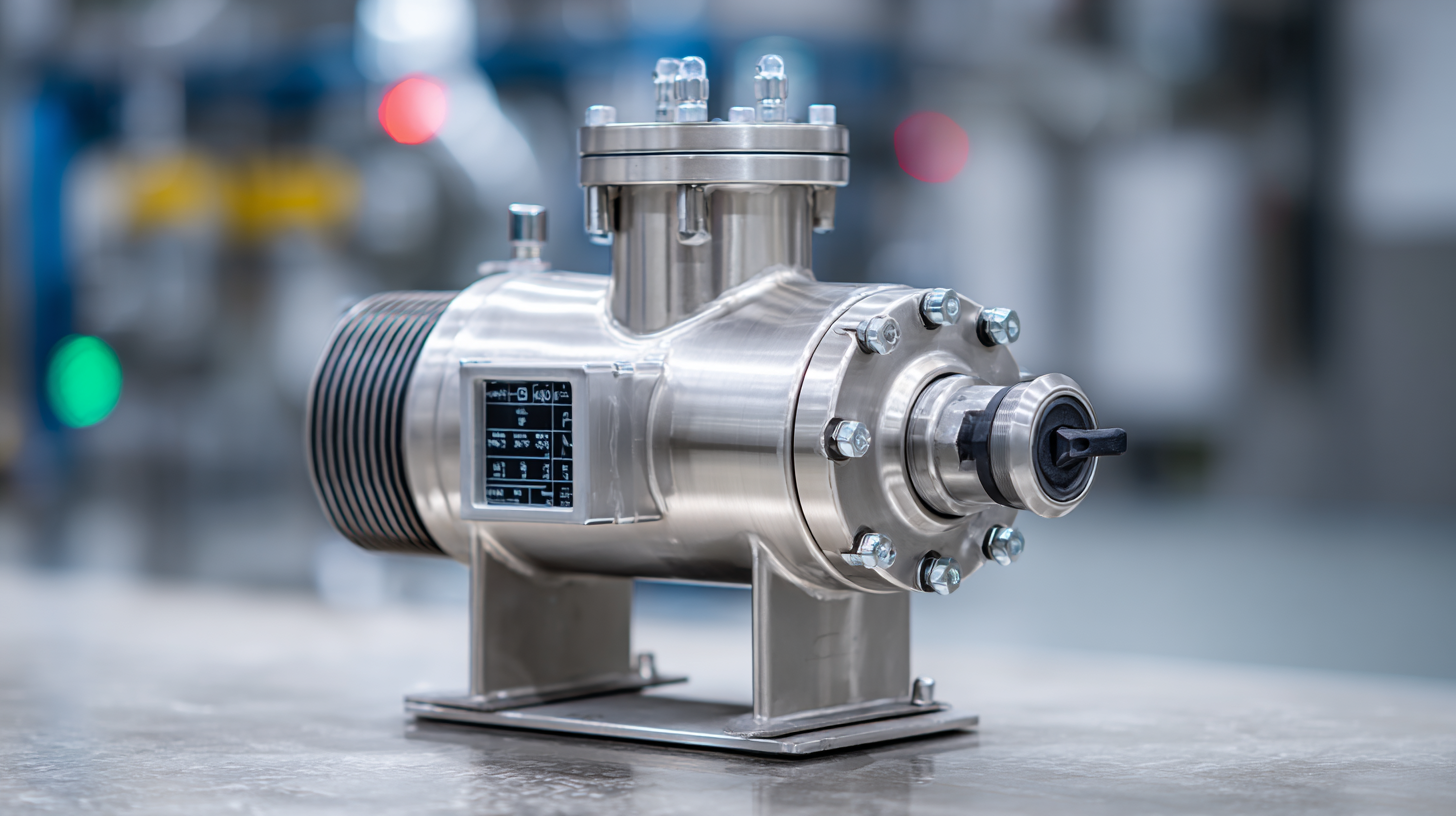

Another type to consider is the diaphragm dosing pump, known for their reliability and precision in delivering set volumes of fluids. Their design allows for reduced pulsation and better control over flow rates, which is essential in processes that require consistency, such as the delivery of therapeutics that leverage cerebrospinal fluid circulation. As the pharmaceutical and biochemical industries evolve, understanding the advantages of each pump type can significantly impact operational efficiency and product quality in industrial settings.

| Pump Type | Flow Rate (L/h) | Pressure (bar) | Power Supply | Applications |

|---|---|---|---|---|

| Diaphragm Dosing Pump | 5 - 50 | 1 - 10 | AC 220V | Water Treatment, Chemical Processing |

| Electromagnetic Dosing Pump | 10 - 100 | 1 - 5 | AC 110V/220V | Food Processing, Pharmaceuticals |

| Hydraulic Dosing Pump | 20 - 200 | 5 - 20 | AC 380V | Oil and Gas, Petrochemicals |

| Pneumatic Dosing Pump | 15 - 150 | 2 - 10 | Compressed Air | Wastewater Treatment, Mining |

When selecting a membrane dosing pump for industrial applications, there are several key factors to consider. First and foremost, the flow rate is crucial; choosing a pump with the appropriate flow rate streamlines chemical dosing processes and ensures optimal performance. According to a report by MarketsandMarkets, the global diaphragm pump market is expected to grow at a CAGR of over 4% from 2021 to 2026, reflecting an increasing demand for efficient dosing solutions. Industries such as water treatment and pharmaceuticals specifically benefit from pumps that offer precise flow control.

Another essential factor is the chemical compatibility of the pump materials. Different industrial applications may involve various corrosive chemicals, which means the pump's diaphragm and body must withstand these substances without degradation. A study by ResearchAndMarkets highlights that the growth in the chemical processing sector has led to a surge in the necessity for durable and resilient pump technologies. Additionally, it's important to account for the operational environment—factors like temperature and pressure can significantly influence pump performance and lifespan. Selecting a pump that aligns with these parameters is vital for operational efficiency and cost-effectiveness.

When selecting a membrane dosing pump for industrial applications, it is crucial to assess its compatibility with the specific fluids and chemicals you plan to use. This ensures optimal performance and longevity of the pump while minimizing maintenance issues. For instance, understanding the viscosity, pH level, and chemical composition of your fluids can guide you towards the right materials for the pump components. Different pumps utilize various materials, including PVC, polypropylene, or stainless steel, which can significantly affect their durability and resistance to corrosion.

Tip: Consider running compatibility tests with your intended fluids before making a purchase. This helps identify any potential reactions that may compromise the pump's efficiency or lead to equipment failure.

Moreover, analyzing the operational conditions such as temperature and pressure is equally important. A pump suitable for ambient temperature may not withstand high temperatures or extreme pressures, leading to performance degradation over time.

Tip: Consult with suppliers or manufacturers to gather information on pump specifications that align with your specific operational environment. This collaborative approach will not only ensure better compatibility but may also afford you insights into innovative options in the market.

When selecting a membrane dosing pump for industrial applications, evaluating performance specifications and pump efficiency is crucial. Start by understanding the flow rate required for your specific processes. Pumps are typically rated by flow capacity, which is measured in liters per hour. It's essential to choose a pump that can handle the required flow without overcommitting your system's energy resources. Additionally, pay attention to the pressure ratings, as inadequate pressure can lead to inefficient dosing and potential operational failures.

Efficiency is another critical factor to consider. A high-efficiency pump will not only save energy but also provide consistent performance over time. Look for pumps with features like adjustable stroke lengths and variable speed controls, which can enhance efficiency by allowing for fine-tuning of the dosing process. Furthermore, consider the maintenance requirements—pumps that are easy to service and have readily available replacement parts can minimize downtime and contribute to a more seamless operation in your industrial setup.

When selecting a membrane dosing pump for industrial applications, maintenance and support play a pivotal role in ensuring the longevity and reliability of the equipment. Regular maintenance routines such as system checks, calibration, and component inspections are essential to prevent unexpected breakdowns. An effective maintenance schedule not only extends the lifespan of the pump but also helps in maintaining optimal performance, minimizing downtime, and enhancing overall productivity.

Moreover, having robust technical support from the manufacturer or supplier can significantly impact the operational efficiency of your dosing pump. Access to professional guidance, troubleshooting, and quick response to parts replacement is vital in addressing any issues that may arise. Investing in a membrane dosing pump that comes with comprehensive support services will help you operate with confidence and reduce the risk of costly disruptions.

Addressing maintenance needs proactively and leveraging expert support can lead to significant cost savings and improved performance in the long run.