In the world of waste management, the Dewatering Press Machine plays a crucial role. Expert Mark Johnson, a leading figure in the industry, states, "Efficiency in waste handling begins with effective dewatering." This machine separates liquids from solids, reducing waste volume significantly. As industries face increasing pressure to manage waste responsibly, the importance of a Dewatering Press Machine cannot be understated.

The mechanics of a Dewatering Press Machine involve applying pressure to slurry. This process extracts moisture while compacting solid materials. In turn, it transforms how organizations handle waste. Many facilities struggle to find the right balance in dewatering processes. As a result, operational efficiency often suffers. However, a well-functioning Dewatering Press Machine can change the game.

Choosing the right Dewatering Press Machine is not always straightforward. Different industries have unique needs, and what works for one may not work for another. Detailed assessments are necessary. Investing time in understanding specific requirements leads to better outcomes. Addressing inconsistencies in dewatering outcomes reveals areas for improvement. The journey towards effective waste management is ongoing, but the right machinery makes a significant difference.

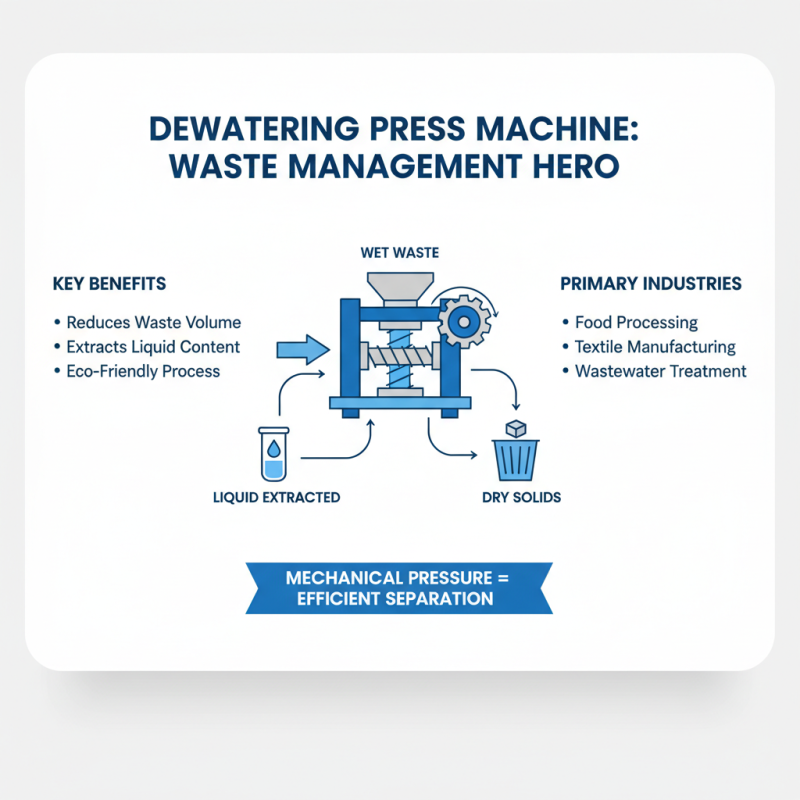

A dewatering press machine is a key tool in waste management. It effectively reduces the volume of waste while extracting liquid content. This process is important for industries like food processing, textiles, and wastewater treatment. The machine uses mechanical pressure to push out water, ensuring dry solids remain.

These machines come in various sizes and designs. They are often equipped with filters that separate solids from liquids. The solid cake produced is easier to handle and dispose of. The liquid extracted can be processed further or disposed of according to regulations. Efficiency and operation method can vary, leading some users to wonder about their effectiveness.

**Tips:** Consider the material being processed. Different types of solids may require different settings. Regular maintenance is crucial. Clogged filters can reduce efficiency, leading to costly downtime. Testing small batches can help prevent larger issues down the line.

A dewatering press machine is critical in waste management and industrial processes. It effectively reduces the water content of sludge and similar materials. The working principle relies on mechanical pressure and separation techniques. As materials enter the machine, they are subjected to force, squeezing excess liquid out. This not only minimizes waste volume but also prepares materials for further processing or disposal.

According to the latest industry reports, dewatering processes can reduce sludge volume by up to 90%. This statistic highlights efficiency, but there are challenges. The energy consumption during operation can be substantial. An operator may encounter fluctuating performance, influenced by the material composition. Proper monitoring is vital to maintain efficiency.

Moreover, maintenance requirements can lead to unplanned downtime. Frequent wear and tear can affect the equipment's longevity. Operators need to balance costs between energy and maintenance to achieve optimal performance. Attention to detail in these areas can often uncover missed savings and efficiency gains. Effective use of a dewatering press demands continuous evaluation and adjustments to maximize its benefits.

A dewatering press machine is crucial in various industries. Its main role is to separate liquids from solids. This machine primarily relies on pressure to achieve effective dewatering. Understanding its key components can provide insights into its operation and efficiency.

The heart of the dewatering press is the filter chamber. This chamber is where the material undergoes separation. The filter plate, typically made of durable materials, helps to hold back solids while allowing liquid flow. In addition, the hydraulic system generates the necessary pressure. A reliable hydraulic pump supplies consistent force for effective dewatering. The drive system, often electric, powers the press mechanism.

Another vital component is the control panel. This panel allows operators to monitor the process. It ensures everything runs smoothly. Sometimes, however, tweaking settings is necessary for optimal performance. Regular maintenance is key, but it can be overlooked. If not addressed, it may lead to inefficiency or malfunctions. By focusing on these components, industries can maximize the benefits of dewatering presses.

Dewatering press machines play a crucial role in various industries. They efficiently remove excess water from sludge, waste, and other materials, which greatly reduces waste volume. This process can lead to significant savings in disposal costs. In the food industry, these machines help separate liquid from solid waste, aiding in the production of compost and reducing landfill waste.

In the municipal sector, dewatering press machines are used to treat sewage sludge. This process minimizes the volume of waste transported to treatment facilities. However, challenges can arise, such as varying sludge compositions that might hinder performance. In the mining industry, these machines handle tailings effectively, yet the maintenance costs can sometimes be high. Their effectiveness depends on regular upkeep and monitoring.

Moreover, in the agricultural field, dewatering press machines assist with processing organic waste. This practice can return valuable nutrients to the soil. Despite these benefits, the initial investment in such machines may seem daunting for small farms. Industry professionals often reflect on how to balance costs and efficiency.

| Industry | Application | Dewatering Method | Benefits |

|---|---|---|---|

| Food Processing | Juice extraction from fruits and vegetables | Mechanical pressing | Higher yield of juice, reduced waste |

| Construction | Soil and sludge dewatering | Belt pressing | Lower transportation costs, environmental compliance |

| Wastewater Treatment | Sludge dewatering | Centrifugation | Reduction of sludge volume, recovery of valuable resources |

| Mining | Concentrate dewatering | Filter pressing | Increased product purity, efficient water use |

| Paper Industry | Pulp dewatering | Vacuum filtration | Improved product quality, lower energy consumption |

Dewatering press machines are essential in various industries. They help remove excess water from sludges or solids. This process leads to more efficient waste management. Using a dewatering press machine can significantly reduce disposal costs. When waste is less dense, transporting it becomes easier and cheaper.

One notable benefit is the improved recovery of valuable materials. For example, in food processing, pressed solids can be reused for animal feed. This not only saves money but also promotes sustainability. On the other hand, not all materials dewater equally. Some may require additional treatment, which complicates the process.

Another advantage is that these machines produce dryer outputs. This decreases the risk of odor and bacterial growth. However, achieving optimal dryness can be challenging and may take time. Users might need to experiment with settings. Over-processing can lead to loss of useful components, which is a factor to reconsider. Therefore, while dewatering press machines offer numerous benefits, careful operation is key.