In the modern era of waste management, the efficiency of processing waste materials has become a critical concern for businesses and municipalities alike. One effective solution that has gained traction is the Dewatering Press Machine, which significantly reduces the volume of waste while extracting valuable liquids, helping to minimize disposal costs and environmental impact. According to Dr. Emily Carter, a renowned expert in waste management technologies, "Investing in a Dewatering Press Machine not only streamlines operations but also supports sustainability goals by reducing landfill contributions."

As the global focus shifts toward environmentally responsible waste management practices, the importance of advanced equipment cannot be overstated. The Dewatering Press Machine stands out as a versatile tool that can be adapted to various waste streams, including municipal sludge, industrial byproducts, and agricultural waste. The technology facilitates efficient separation of water from solids, substantially enhancing the end product's quality and marketability.

Understanding the benefits of incorporating a Dewatering Press Machine into waste management strategies is crucial for organizations aiming to improve their bottom line while contributing to a greener planet. As we navigate the complexities of waste disposal in an increasingly regulated environment, the insights provided by industry leaders like Dr. Carter highlight the vital role such machinery plays in promoting effective and responsible waste management solutions.

Dewatering press machines are essential tools in waste management, designed to efficiently separate liquids from solids. These machines utilize powerful hydraulic pressure to compress waste materials, significantly reducing their volume and facilitating easier disposal or recycling. By operating through a straightforward mechanism, dewatering presses can effectively handle various waste types, including industrial sludge, organic waste, and even municipal waste, making them versatile solutions for different sectors.

The functionality of dewatering press machines lies in their ability to enhance both environmental sustainability and operational efficiency. During processing, waste is fed into the machine, where it undergoes a pressing cycle that forces moisture out of the material. This not only minimizes the quantity of waste that needs to be transported to landfills but also transforms the byproduct into a more manageable and dry form. The result is a significant decrease in disposal costs and an increase in the potential for recycling materials, contributing to a circular economy. Understanding how these machines function can aid businesses in choosing appropriate waste management solutions that align with their operational goals and environmental responsibilities.

Dewatering press machines have become an essential tool in the waste management industry, offering a range of benefits that significantly enhance operational efficiency. One of the primary advantages of using these machines is their ability to reduce waste volume. According to a report by the Environmental Protection Agency (EPA), dewatering can lead to a volume reduction of up to 90% for certain types of waste, such as sewage sludge and food waste. This substantial decrease not only saves on transportation costs but also decreases landfill usage, promoting more sustainable waste management practices.

Moreover, dewatering presses improve the handling and processing of waste materials. The solid fractions produced after dewatering are easier to manage and can often be repurposed or further processed. A study published in the Waste Management Journal indicated that facilities utilizing dewatering technology reported an increase in the material recovery rate by nearly 30%. This not only contributes to a circular economy by allowing previously discarded materials to be reused but also strengthens compliance with regulations regarding waste diversion and recycling targets. By investing in dewatering press machines, organizations can significantly enhance their waste management strategies, leading to both economic and environmental benefits.

| Benefit | Description | Environmental Impact | Cost Savings |

|---|---|---|---|

| Efficient Waste Reduction | Reduces the volume of waste significantly by removing excess moisture. | Decreases landfill use, helping to preserve natural resources. | Lower disposal costs due to reduced waste volume. |

| Improved SSI Handling | Facilitates easier handling and transportation of solid waste. | Minimizes environmental hazards related to waste spills. | Reduced labor costs due to easier handling. |

| Resource Recovery | Enables recovery of valuable materials from waste streams. | Promotes recycling and sustainability efforts. | Potential revenue from selling recovered materials. |

| Operational Efficiency | Automated processes reduce the need for manual labor. | Decreases the carbon footprint associated with waste processing. | Lower operational costs due to reduced workforce requirements. |

| Compliance with Regulations | Helps meet local and national waste management regulations. | Reduces risk of fines and legal issues related to waste disposal. | Avoidance of costs associated with compliance violations. |

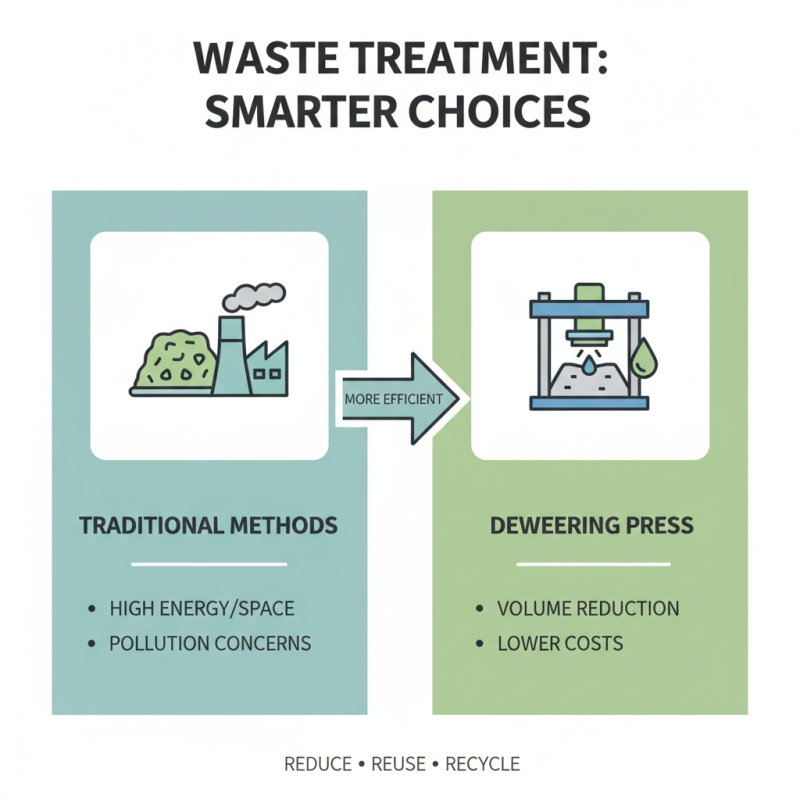

When evaluating waste treatment methods, it's crucial to consider the advantages of dewatering press machines compared to traditional approaches. Traditional waste treatment methods, such as landfilling or incineration, often require significant amounts of energy and space. These methods can lead to environmental concerns, including greenhouse gas emissions and potential groundwater contamination. In contrast, dewatering presses effectively reduce the volume of waste material through mechanical means, minimizing the reliance on landfills and lowering transportation costs associated with waste disposal.

The operational efficiency of dewatering presses presents a striking advantage over conventional methods. By mechanically extracting water from sludge, these machines provide a solid waste output that is easier to handle and more suitable for further processing or recycling. This not only reduces the weight and volume of waste, making it less costly to transport, but it also enhances the overall sustainability of waste management practices. Additionally, the reduced moisture content of the processed waste can lead to lower operational costs in waste treatment facilities, fostering a more eco-friendly approach to waste management while simultaneously improving efficiency.

When choosing a dewatering press machine for waste management, several key factors should be taken into consideration to ensure optimal performance and efficiency. First, assess the type and volume of waste that will be processed. Different machines cater to specific materials, such as municipal solid waste, industrial sludge, or agricultural by-products. Understanding the characteristics of the waste, including its moisture content and solid composition, is essential in selecting a machine that can handle these requirements effectively.

Another critical factor is the machine's capacity and processing speed. Determine the daily volume of waste you need to treat and compare that with the output capabilities of potential machines. Moreover, consider the energy consumption and maintenance costs associated with the device. A machine that is energy-efficient not only reduces operational expenses but also minimizes the carbon footprint. Lastly, look for features that enhance user-friendliness and safety, such as automated controls, ease of cleaning, and built-in safety mechanisms. By meticulously evaluating these factors, you can select a dewatering press machine that suits your specific waste management needs while ensuring a reliable and cost-effective operation.

Operating and maintaining a dewatering press machine effectively is essential for optimizing waste management processes. According to industry reports, efficient dewatering can reduce the volume of sludge by up to 90%, leading to significant reductions in transport and disposal costs. To achieve these results, it is crucial to follow best practices during both operation and maintenance. Regular inspection and servicing of the machine are necessary to ensure that all components are functioning correctly. This includes checking the hydraulic systems, belts, and the dewatering screens for any signs of wear and tear that could affect performance.

Additionally, operator training plays a vital role in maximizing efficiency. Understanding the machine's capabilities, including the type of waste being processed and the optimal operating conditions, can lead to uninhibited performance. Studies indicate that well-trained personnel can increase throughput by as much as 30% compared to less experienced operators.

Furthermore, keeping accurate records of operation can help identify patterns and areas for improvement, ensuring that the machine runs at its peak performance while adhering to best practices in waste management. By emphasizing these operational and maintenance strategies, organizations can ensure their dewatering press machines work efficiently, leading to better waste management outcomes.