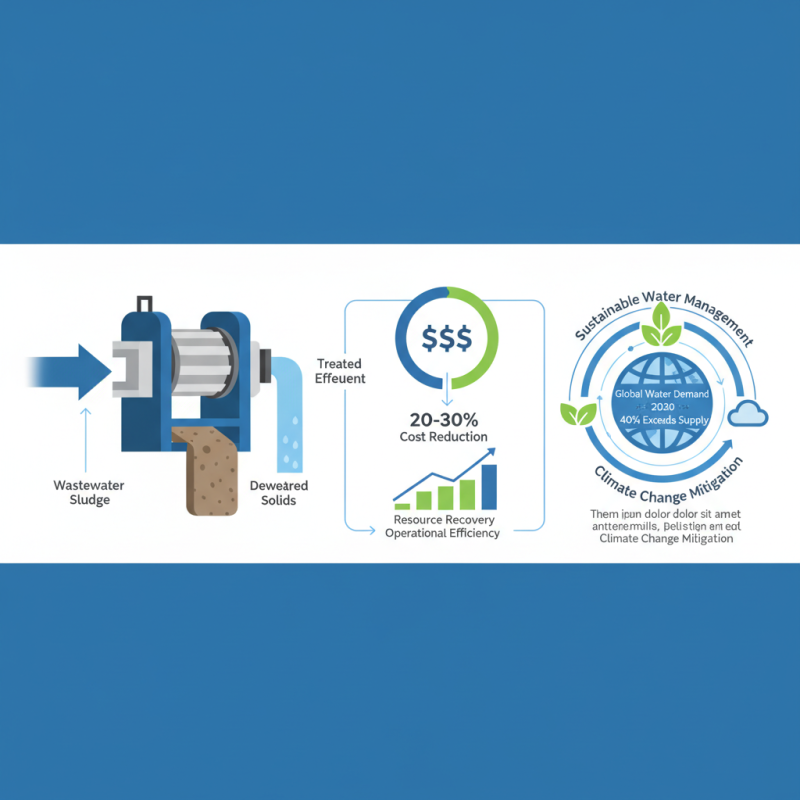

In the realm of wastewater management, the efficiency of dewatering processes is crucial for reducing operational costs and enhancing resource recovery. The use of a Dewatering Press is a pivotal technique that has gained significant attention due to its ability to extract water from sludge and other waste materials. According to the World Bank, it is estimated that by 2030, the global water demand will exceed supply by 40%. Consequently, the implementation of efficient dewatering techniques is emerging as a necessity, not only for effective wastewater treatment but also for promoting sustainable water management practices.

Recent industry reports indicate that optimizing dewatering methods can lead to a 20-30% reduction in the overall costs associated with sludge handling and disposal. As municipalities and industries increasingly grapple with the challenges posed by rising populations and stringent environmental regulations, adopting advanced Dewatering Press technologies can streamline operations and improve the quality of treated effluent. Furthermore, the transition towards more energy-efficient and sustainable dewatering solutions aligns with global efforts to mitigate climate change impacts while addressing wastewater management challenges. Through this lens, exploring the best dewatering press techniques becomes not only an operational priority but also a strategic necessity for sustainable development.

Dewatering press techniques play a pivotal role in effective wastewater management, as they significantly reduce the volume of sludge produced during wastewater treatment processes. A report from the Water Environment Federation indicates that implementing dewatering technologies can reduce sludge volume by up to 90%, leading to lower transport and disposal costs. Various methods, including mechanical presses, belt filter presses, and rotary drum thickening, are utilized to enhance efficiency and minimize environmental impact.

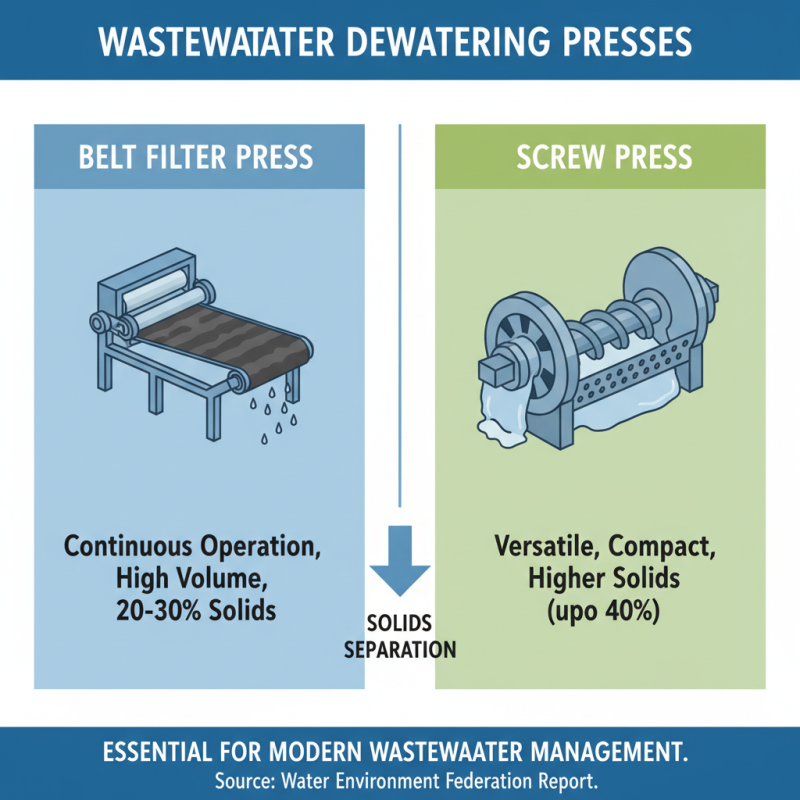

Mechanical dewatering presses, for instance, utilize pressure to remove water from sludge, resulting in drier cake solids. According to industry studies, these systems can achieve a solids content of 20-30%, making them particularly effective for treating municipal and industrial wastewater. Additionally, belt filter presses are renowned for their continuous operation and ability to process large volumes of sludge, making them suitable for facilities with high treatment demands. By optimizing these techniques, wastewater treatment plants can not only comply with regulatory requirements but also recover resources, such as biogas and nutrients, contributing to a more sustainable wastewater management cycle.

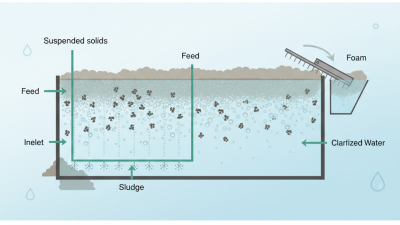

Wastewater dewatering is a crucial process that significantly enhances the efficiency of wastewater management. At its core, dewatering refers to the removal of water from sludge, thereby reducing its volume and making it easier to handle and transport. The process generally involves various techniques such as mechanical pressing, centrifugation, and thermal drying, all of which are designed to separate water from solid waste effectively. By reducing the water content, treatment facilities can lower transportation costs, minimize disposal space, and mitigate environmental impact.

The principles behind wastewater dewatering revolve around the understanding of both physical and chemical properties of the sludge. Mechanical methods, for instance, apply pressure to squeeze water out of the sludge, while centrifugation relies on centrifugal force to accelerate the separation process. Chemical agents may also be introduced to enhance flocculation, making it easier for solids to clump together and separate from the liquid. Through these methods, facilities can achieve a significant reduction in water content, often down to under 20%, leading to a more manageable end product ready for further treatment or disposal.

Dewatering presses are indispensable tools in modern wastewater management, facilitating the efficient separation of solids from liquids. Among the common types used today, belt filter presses and screw presses stand out for their effectiveness and versatility. According to a recent industry report from the Water Environment Federation, belt filter presses are particularly well-regarded for their continuous operation and ability to handle large volumes of sludge while achieving a solid content of around 20% to 30%. This capability makes them ideal for municipal wastewater treatment plants dealing with varying sludge characteristics.

Screw presses, on the other hand, are gaining popularity due to their compact design and reduced operational footprint. The American Society of Civil Engineers notes that these presses can achieve a higher dewatering efficiency, often exceeding 30% solids content, while using less energy compared to traditional methods. Their ability to process a wide range of feed materials, from municipal sludge to industrial waste, coupled with lower maintenance costs, makes screw presses a preferred choice in many facilities. Overall, the advancements in dewatering press technology continue to drive improvements in wastewater management, enhancing not only efficiency but also environmental sustainability.

Efficient dewatering is crucial for effective wastewater management, and several factors significantly influence its efficiency and performance. One key factor is the type of sludge being processed—different compositions, such as organic or inorganic, require tailored approaches for optimal dewatering. According to a report by the Water Environment Federation, effective dewatering can reduce the volume of sludge by up to 90%, demonstrating how critical it is to select appropriate techniques based on sludge characteristics. Additionally, the operational parameters such as pressure, temperature, and moisture content also play a vital role in enhancing water removal efficiency.

To improve dewatering performance, consider implementing a few practical tips. First, routinely monitor and adjust the feed rate to match the dewatering capacity. Overloading can hinder performance and increase energy consumption. Second, pre-treatment methods such as coagulant addition can improve flocculation, thereby increasing the overall efficiency of the dewatering process. Lastly, regular maintenance of the dewatering equipment ensures sustained performance and minimizes downtime.

Another factor to consider is the role of polymer additives which can enhance dewatering outcomes. A study by the Environmental Protection Agency indicated that the right choice of polymers can increase solid recoveries by 20-30%. Therefore, understanding the interactions between polymers and sludge constituents is essential for optimizing dewatering efforts in wastewater management.

Implementing a dewatering press system effectively can greatly enhance wastewater management, particularly in industries that generate large volumes of sludge. One of the best practices is to conduct a thorough assessment of the sludge characteristics before selecting a dewatering technology. Data shows that flocculation and polymer addition can improve the dewatering efficiency by up to 30%, depending on the organic content and particle size of the sludge. According to a report from the Water Environment Federation, optimizing chemical dosing not only aids in achieving better solids concentration but also reduces operational costs significantly.

Training and maintenance are equally critical. Regular training for operators on the best operational practices can lead to a reduction in downtime and improved system performance. A report from the International Society for Waste Management highlights that well-trained personnel can enhance the lifespan of dewatering equipment by up to 25%. Additionally, establishing a routine maintenance schedule ensures the system operates at its peak efficiency, further maximizing the moisture removal rates, which can range from 70% to 90% depending on the dewatering method employed. By focusing on these critical practices, wastewater facilities can significantly improve their dewatering performance and overall operational efficiency.