Dispersed Air Flotation (DAF) is a technique that has transformed wastewater treatment. Experts in the field, such as Dr. Emily Carter, emphasize its advantages: “Dispersed Air Flotation efficiently separates solids and oils from water, enhancing treatment efficacy.” This process utilizes microbubbles to lift contaminants to the surface, where they can be easily removed.

DAF is particularly impactful in industries like food processing and oil refining. The technology reduces the need for harsh chemicals while using less energy than other methods. It holds promise for increasing efficiency in water treatment facilities. However, the implementation isn't flawless. Some facilities struggle with bubble sizes and hydraulic retention times.

Also, operational challenges can arise, such as varying influent characteristics. Addressing these imperfections is essential for maximizing DAF's potential. The field continues to evolve, and ongoing research will be critical in refining techniques and applications. Ultimately, Dispersed Air Flotation remains a vital process in achieving cleaner water and a healthier environment.

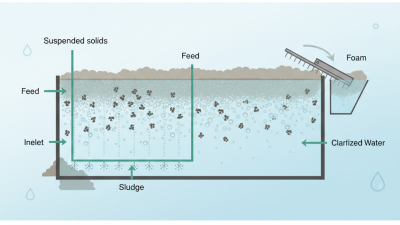

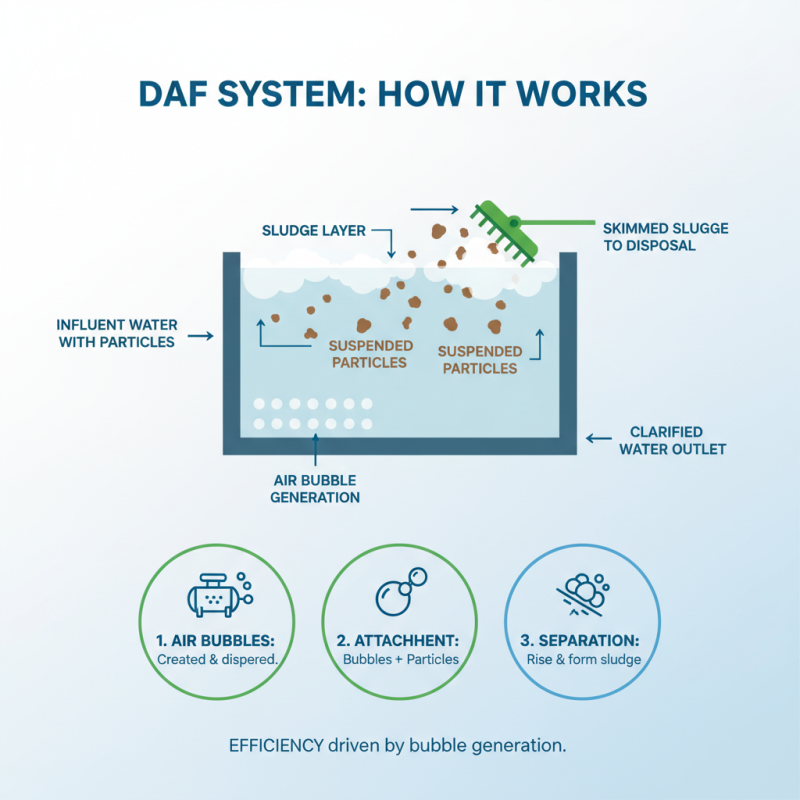

Dispersed Air Flotation (DAF) is an innovative water treatment technology. It uses small air bubbles to remove impurities. The process involves introducing air into water under pressure. When this pressure is released, fine bubbles form. These bubbles attach to suspended particles and rise to the surface.

Studies suggest that DAF systems can achieve up to 90% removal efficiency for various pollutants. This efficiency makes DAF suitable for treating industrial wastewater. However, the effectiveness can vary based on water quality and system design. For instance, water with high turbidity may require additional pre-treatment.

The complexity of DAF systems may pose challenges. Proper operation requires skilled personnel. Additionally, maintenance can be demanding. Some facilities report frequent downtime due to equipment issues. Balancing operational costs with the benefits of DAF can also be difficult. Despite these challenges, DAF remains a promising method for effective water treatment.

Dispersed Air Flotation (DAF) technology is a process designed to remove suspended solids, oils, and other contaminants from wastewater. It operates on simple principles that involve microbubbles. The microbubbles attach to solids, increasing their buoyancy. Consequently, these solids rise to the surface and form a froth layer. This layer is then skimmed off, allowing for clearer water.

Research indicates that DAF can achieve over 90% removal efficiency for certain types of pollutants. A report from the Water Environment Federation states that this technology can treat flow rates ranging from 10 to over 1000 gallons per minute. DAF systems are well-regarded in municipal and industrial applications. They are effective, yet they often encounter issues with bubble generation. Some systems struggle to maintain consistent air saturation levels. This inconsistency can affect removal efficiency and overall performance.

In practice, operators may face challenges in optimizing conditions for maximum efficiency. Factors like pH and temperature can influence performance. Regular maintenance is crucial to ensure that microbubble generators work effectively. Over time, systems may require adjustments to adapt to changing wastewater characteristics. This ongoing need for oversight highlights the importance of having well-trained personnel on hand.

Dispersed Air Flotation (DAF) systems consist of several key components that work together. Air bubbles are the heart of this technology. These bubbles attach to suspended particles in water, causing them to rise and eventually form a sludge layer on the surface. The efficiency of bubble generation impacts the overall performance.

Another crucial component is the flotation tank. This tank's design influences the separation process significantly. Its size and shape should facilitate optimal bubble formation and rising rates. Additionally, the influent feed system plays a vital role. Proper feed distribution ensures that all parts of the tank receive equal treatment.

Valves and pumps are also important in a DAF system. They regulate air release and control flow rates. If any component is not functioning properly, the entire system may underperform. It's essential to conduct regular maintenance and inspections. This proactive approach can uncover inefficiencies in components that might otherwise go unnoticed.

Dispersed Air Flotation (DAF) is a treatment method gaining traction in the water industry. Its applications are broad, particularly in municipal and industrial wastewater processing. DAF uses tiny air bubbles to separate pollutants from water. This technology effectively reduces solid waste, oils, and fats.

A report by the Water Environment Federation indicates that DAF systems can achieve up to 95% removal efficiency for suspended solids. This performance makes it ideal for food processing and petrochemical facilities. In these sectors, efficient water treatment is crucial. Water quality impacts product safety, regulatory compliance, and operational costs.

Despite its advantages, DAF has challenges. Not all wastewater types respond well to this method. High turbidity or varying pH can hinder effectiveness. Operators must monitor water characteristics closely. Large-scale applications may require significant investment in infrastructure. Continuous adjustments and testing are necessary to ensure optimal performance. This adds complexity, yet the benefits in treatment efficiency often outweigh the hurdles.

| Application Area | Description | Efficiency | Typical Usage |

|---|---|---|---|

| Municipal Wastewater Treatment | Used to remove suspended solids and fats from wastewater. | Up to 90% removal efficiency of solids. | Used in treatment plants for domestic wastewater. |

| Industrial Effluent Treatment | Effective in treating industrial effluents containing oils and grease. | Can achieve over 80% efficiency in oil removal. | Applicable in industries like food processing, petrochemicals. |

| Dairy Industry | Reduces biological oxygen demand and suspended solids in dairy effluents. | Removes up to 92% of solids and COD. | Used in dairy processing to treat wash water. |

| Oil Recovery | Separates oil from water for recycling and recovery. | Can recover up to 95% of free oil from wastewater. | Used in oil refineries and oil spill cleanup. |

| Aquaculture | Treats wastewater and effluents from fish farms. | Removes up to 85% of suspended solids and nutrients. | Utilized in fish farms to manage water quality. |

Dispersed Air Flotation (DAF) is a method used to separate contaminants from water. It injects air into the water, creating bubbles that attach to particles. These bubbles help lift contaminants to the surface for easy removal.

One major advantage of DAF is its efficiency. It can treat a wide range of wastewater types. This method is effective for removing oils, fats, and solids. However, not everything is perfect. Some contaminants may not float easily. This could lead to incomplete treatment.

Tips: Always monitor the air flow rates. Proper adjustment can improve removal efficiency. Additionally, regular maintenance of the system is crucial. Over time, wear and tear can diminish performance.

Another limitation is the sludge produced during the process. Managing this sludge adds complexity. Proper disposal solutions are essential. Without them, treatment can become counterproductive.