Dissolved Air Flotation (DAF) has emerged as a critical technology in the water treatment sector, effectively addressing various challenges associated with water quality management. According to the American Water Works Association, over 80% of municipal water treatment facilities are now incorporating innovative technologies like DAF to enhance their operational efficiency and compliance with increasingly stringent regulations. The method utilizes microbubbles to separate solids and oils from water, ensuring a cleaner effluent while minimizing chemical usage.

Dr. Emily Carter, a leading expert in water treatment technologies, highlights the significance of DAF, stating, "The application of Dissolved Air technologies has revolutionized wastewater management, allowing facilities to achieve higher standards of clarity and reduced environmental impact." As industries strive for sustainable practices, DAF not only meets regulatory demands but also promotes resource recovery, turning waste into valuable byproducts. This introductory overview underscores the growing reliance on Dissolved Air solutions in the quest for effective and environmentally friendly water treatment options.

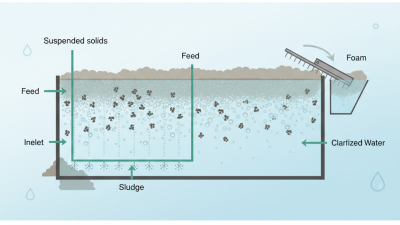

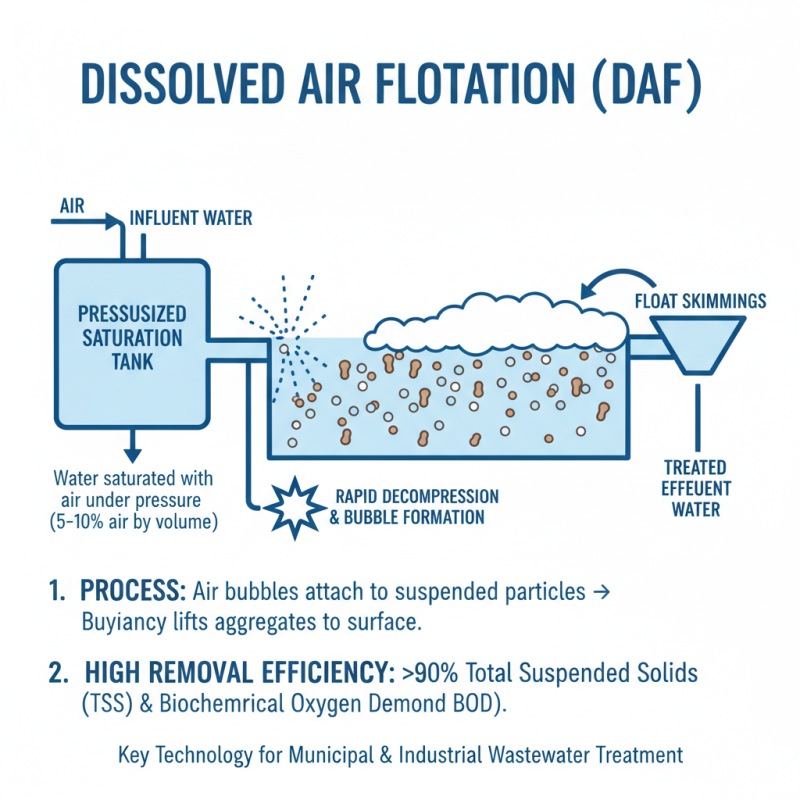

Dissolved Air Flotation (DAF) technology has emerged as a prominent method in water treatment processes, known for its efficacy in removing suspended solids, oils, and other contaminants. The core principle of DAF involves saturating water with air under pressure and then releasing it into a flotation tank. As the pressure drops, tiny air bubbles form that adhere to the impurities, causing them to rise to the surface. This results in a concentrated layer of contaminants that can be easily removed.

One of the significant advantages of DAF technology is its ability to operate effectively across various water qualities and flow rates. Its versatility makes it suitable for different applications, including municipal wastewater treatment, industrial effluent management, and surface water purification. Moreover, DAF systems are often compact compared to traditional methods, allowing them to be implemented in limited spaces without sacrificing performance. As a result, DAF serves as a sustainable solution that not only enhances water quality but also supports environmental protection efforts.

| Parameter | Description | Typical Values |

|---|---|---|

| Superficial Loading Rate | Rate at which the water moves through the flotation unit | 5 - 15 m/h |

| Dissolved Air Ratio | The ratio of air dissolved to the volume of water treated | 15 - 30% |

| Bubble Size | Diameter of the air bubbles generated in the process | 50 - 100 microns |

| Removal Efficiency | Percentage of contaminants removed from water | 80 - 95% |

| Coagulant Type | Chemical used to enhance the flotation process | Alum, Ferric Chloride |

Dissolved air flotation (DAF) has emerged as a pivotal technology in the water treatment sector, leveraging its unique principles of operation to enhance the removal of suspended solids, oils, and other contaminants from water. The process begins with the saturation of water with air under pressure, typically achieving about 5-10% air by volume. Upon rapid decompression, tiny air bubbles form, attaching themselves to the suspended particles in the water. This phenomenon, known as buoyancy, causes these aggregates to rise to the surface, allowing for effective separation during the flotation process. According to industry reports, DAF systems can achieve removal efficiencies of 90% or more for both total suspended solids and biochemical oxygen demand (BOD) levels, making them particularly effective in municipal and industrial wastewater treatments.

The operational efficiency of DAF systems also hinges on specific design parameters such as bubble size, flow rates, and hydraulic loading. Research indicates that optimally sized bubbles—typically ranging from 20 to 100 microns—create a greater surface area for attachment to contaminants, thereby increasing overall performance. Furthermore, the use of various coagulants and flocculants can significantly enhance contaminant removal rates, addressing the needs of diverse water quality conditions. With the growing emphasis on sustainable water management practices, the integration of DAF technology is increasingly recognized as an effective solution to meet stringent regulatory standards and improve environmental outcomes in water treatment operations.

Dissolved Air Flotation (DAF) is a widely adopted technology in water treatment processes, particularly effective for the removal of suspended solids, oils, and grease. According to a report by the Water Environment Federation, DAF systems can achieve over 90% removal efficiency for various contaminants under optimal operational conditions. This high efficacy makes it especially valuable in industrial applications, including food processing, pulp and paper manufacturing, and wastewater treatment. The technology works by saturating water with air under pressure, which, when released, forms microbubbles that attach to suspended particles, causing them to float to the surface for removal.

In municipal wastewater treatment, DAF systems are increasingly utilized due to their ability to handle varying inflow conditions and high solids concentration. The U.S. Environmental Protection Agency (EPA) highlights that DAF can improve the treatability of wastewater, allowing for enhanced performance and compliance with stringent discharge standards. Furthermore, DAF’s compact design and low energy requirements make it an attractive option for modern water treatment facilities striving for efficiency and sustainability. As cities expand and the demand for clean water intensifies, DAF technology stands out as a reliable solution contributing to effective water purification practices across various sectors.

Dissolved Air Flotation (DAF) is an innovative water treatment technology that offers numerous benefits for both industrial and municipal applications. One of its primary advantages is the effective removal of suspended solids, oils, and other contaminants from water. By introducing microbubbles into the water, DAF creates an environment that encourages contaminants to rise to the surface, where they can be easily skimmed off. This process not only enhances water clarity but also improves the overall quality of treated water, making it suitable for various uses, including reuse and discharge.

Moreover, DAF systems are known for their efficiency and compact design. Compared to traditional sedimentation methods, DAF requires significantly less space and can operate under a variety of conditions, allowing for high-flow treatment even in confined spaces. The gentle process reduces the risk of damaging sensitive particles, ensuring that valuable resources are preserved. Additionally, DAF can often be integrated seamlessly with other treatment processes, maximizing efficiency and effectiveness in meeting regulatory standards. This versatility further solidifies its role as a preferred choice for efficient water treatment solutions.

When implementing Dissolved Air Flotation (DAF) systems for water treatment, several best practices can significantly enhance their effectiveness. Firstly, it is crucial to optimize the design parameters of the DAF system to match specific water characteristics. This includes understanding the influent water quality, such as turbidity levels and the presence of different contaminants. Tailoring the system’s configuration, including the size and number of flotation cells, can improve performance and lead to more efficient separation of suspended solids and oils.

Secondly, maintaining proper chemical dosing and air saturation levels is vital for maximizing DAF efficiency. The use of coagulants or flocculants can aid in the aggregation of solid particles, making them easier to float. Additionally, ensuring the correct ratio of recycled effluent to influent water enhances the saturation of air, which is essential for the creation of microbubbles. These microbubbles bond with the solid particles, facilitating their rise to the surface for skimming, thereby promoting optimal separation and treatment effectiveness. Regular monitoring and adjustments of these parameters can lead to improved operational consistency and water treatment outcomes.