Dissolved Air plays a crucial role in modern water treatment systems. It is essential for removing impurities and enhancing water quality. According to the World Health Organization, approximately 2 billion people lack access to safe drinking water. This highlights the urgent need for effective treatment methods. Dissolved Air helps to facilitate processes like flotation, which separates solids from liquids.

In many treatment facilities, the incorporation of Dissolved Air can significantly improve efficiency. The National Environmental Education Foundation states that up to 60% of water pollution originates from urban runoff. By utilizing Dissolved Air flotation, facilities can target these contaminants more effectively. Additionally, elevated levels of dissolved oxygen can promote the growth of beneficial microorganisms. However, maintaining the right balance is often a challenge.

While the benefits are clear, there are areas for improvement. Some systems may struggle with optimizing air saturation levels. This issue can lead to inconsistencies in treatment outcomes. As the industry evolves, addressing these shortcomings in Dissolved Air application will be vital for future advancements in water treatment.

Dissolved air plays a crucial role in water treatment systems. It helps in the removal of pollutants and enhances water clarity. When air is dissolved in water, it promotes the agglomeration of particles. These particles then rise to the surface, making it easier to remove them. This process is fundamental to achieving cleaner water.

The significance of dissolved air extends to improving the efficiency of filtration systems. Aeration helps in maintaining healthy microbial communities that break down organic matter. Without adequate dissolved air, these systems struggle to function optimally. Many treatment facilities face challenges with oxidation and sedimentation due to insufficient air levels.

However, there can be drawbacks. Excessive dissolved air might lead to foaming issues, complicating operations. Balancing air levels is not always easy. Monitoring technology can sometimes fall short. Operators may need to adjust processes frequently, which can be frustrating. Understanding the dynamics of dissolved air is vital to overcoming these challenges.

| Parameter | Description | Impact of Dissolved Air |

|---|---|---|

| Oxygen Levels | The amount of dissolved oxygen in water. | Essential for aerobic bacteria involved in breaking down organic materials. |

| Removal of Contaminants | Dissolved air flotation (DAF) helps in lifting floating debris and contaminants. | Enhances the efficiency of removal processes in treatment systems. |

| pH Levels | The acidity or alkalinity of the water. | Dissolved air can aid in regulating pH levels, contributing to optimized chemical treatment. |

| Turbidity Reduction | Measurement of cloudiness in water due to particles. | Dissolved air aids in flocculation that helps in settling out suspended solids. |

| Nutrient Levels | Concentration of essential nutrients in water. | Promotes the growth of beneficial microorganisms that support water quality. |

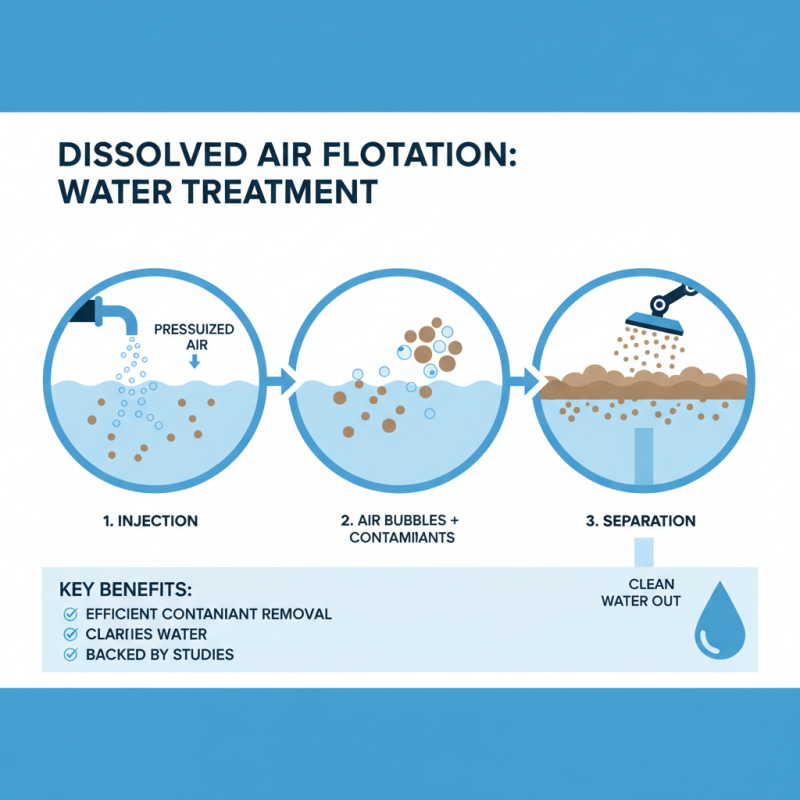

Dissolved air plays a crucial role in water treatment, especially in the process of dissolved air flotation (DAF). This method uses tiny air bubbles to remove impurities from water. When the air is dissolved under pressure and then released, it forms bubbles that attach to particles. This process causes the particles to rise to the surface. Here, they can be easily skimmed off.

DAF systems are effective because they enhance the removal of suspended solids, oils, and other contaminants. The efficiency of this process depends on the size of the bubbles, which should ideally be small. Larger bubbles tend to rise too quickly, failing to capture contaminants. Remember, using appropriate pressure helps maintain optimal bubble size for better removal efficiency.

**Tip:** Regular maintenance of the DAF system is essential. Clogs or malfunctions can reduce performance significantly. Consider regular checks on pressure regulators and air dissolving units. If you notice bubbles not forming properly, it may indicate an underlying issue.

Dissolved air flotation systems also offer advantages over traditional sedimentation methods. They require less space and can operate effectively in various conditions. However, not every water source is suitable for this technique. It’s important to evaluate the specific contaminants present in the water before deciding.

Dissolved air plays a crucial role in water treatment systems. Its effectiveness in removing contaminants is backed by various studies. When bubbles of air are injected into water, they attach to suspended particles. This process, known as flotation, allows contaminants to rise and be removed more efficiently.

Research indicates that using dissolved air can enhance contaminant removal rates by 90% in some systems. For instance, a major study showed that adding dissolved air led to a 60% reduction in turbidity levels. These figures highlight the quantitative impact of dissolved air on water quality.

However, the implementation of dissolved air flotation systems is not without its challenges. Equipment maintenance is critical. Proper control of air saturation levels is vital for optimal performance. Some facilities struggle with air bubble size, impacting removal efficiency. It's essential to address these issues to maximize the potential of dissolved air in water treatment.

Dissolved air flotation (DAF) systems have gained traction in water treatment. They differ from traditional methods like sedimentation. DAF technology uses dissolved air to enhance separation efficiency. Studies indicate that DAF can remove over 90% of suspended solids. This is a significant improvement compared to conventional approaches.

In traditional water treatment, sedimentation relies on gravity. This process can be slow and less effective for small particles. DAF, on the other hand, injects air into wastewater. This produces microbubbles. The bubbles attach to contaminants, making them rise rapidly to the surface. This flotation leads to faster processing times. Research shows DAF systems can reduce treatment time by up to 50% in some cases.

Challenges exist with DAF systems. The continuous operation requires careful management of dissolved air levels. Instability can lead to inefficiencies. Sometimes, the chemistry of the water changes, affecting performance. The potential for foaming and scum formation is also a concern. These factors need to be monitored closely. This reflection on operational complexities highlights how DAF systems, while effective, require ongoing evaluation.

Dissolved air plays a crucial role in water treatment systems. It helps remove contaminants effectively. Case studies reveal how dissolved air improves treatment efficiency in various facilities. In one case, a municipal plant utilized this method. The results were remarkable, with significant reductions in pollutants.

In another example, an industrial facility experienced challenges with sludge handling. By integrating dissolved air flotation, they optimized the process. This adjustment increased handling capacity and reduced operational costs. These cases highlight the transformative power of dissolved air in diverse settings.

However, challenges remain. Some systems may deal with equipment malfunction. Air saturation levels are critical and can fluctuate. Continuous monitoring is essential. It ensures optimal performance and addresses any inefficiencies. Overall, these insights demonstrate that while dissolved air is effective, there’s always room for improvement.