In the quest for efficient water treatment solutions, the Lamella Clarifier stands out as an innovative technology that enhances the clarification process while optimizing space and operational efficiency. This article aims to guide you through the effective utilization of a Lamella Clarifier to achieve the best results in water treatment applications. By understanding its design and operational mechanisms, you can streamline your treatment processes, reduce costs, and enhance water quality.

The Lamella Clarifier operates on the principle of gravity separation, which significantly improves sedimentation time and increases clarity. Its unique design facilitates a larger surface area for settling, making it particularly advantageous in treating large volumes of water. In this guide, we will explore the essential factors influencing the performance of a Lamella Clarifier, including its configuration, flow rates, and maintenance practices to ensure its optimal functionality. With practical insights and tips, this article will equip water treatment professionals and facility operators with the necessary knowledge to leverage this technology effectively.

By embracing the capabilities of a Lamella Clarifier, you can ensure a more sustainable and efficient approach to managing water resources, addressing both environmental concerns and regulatory requirements. Join us as we delve deeper into the strategies that can elevate your water treatment processes to new heights.

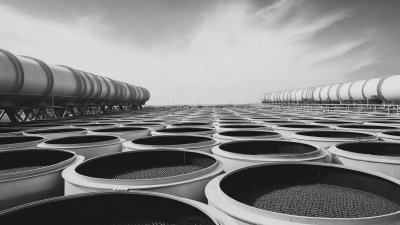

Lamella clarifiers are integral components in modern water treatment systems, designed to enhance the sedimentation process through their innovative design and functionality. Unlike traditional clarifiers, which require larger surface areas and longer retention times, lamella clarifiers utilize inclined plates to increase the effective settling area without extending the footprint. This configuration allows for a more compact system that optimizes the clearance of suspended solids from wastewater, making it particularly beneficial for facilities handling complex flows, such as those found in industrial settings.

Recent advancements in wastewater treatment demonstrate the relevance of lamella clarifiers in various sectors. For instance, a facility in the southern U.S. successfully integrated a bottom ash dewatering and clarifying system that emphasizes the necessity for effective solid-liquid separation in resource recovery processes. Furthermore, major projects like a new modular wastewater treatment plant in Mali reflect the industry's movement towards efficient systems that utilize innovative technologies, including lamella clarifiers, to address specific challenges in mineral processing. According to industry reports, these units can achieve up to 90% solids removal efficacy, underscoring their importance in contemporary water management strategies.

Lamella clarifiers have emerged as a pivotal tool in modern water treatment processes, offering significant advantages over traditional settling methods. One of the primary benefits of lamella clarifiers is their ability to optimize space and increase treatment efficiency. According to a study by the Water Environment Federation, lamella clarifiers can reduce the footprint required for sedimentation, achieving up to 90% more efficiency in a given area compared to conventional systems. This compact design is especially beneficial for urban settings where space is at a premium.

Another key advantage is their enhanced solids removal capability. Research published in the Journal of Environmental Engineering indicates that lamella clarifiers can achieve solids removal efficiencies exceeding 99%, which is essential for maintaining water quality standards. The advanced design facilitates the rapid settling of particles due to the inclined plates, which not only improves settled water quality but also allows for increased flow rates. As a result, facilities equipped with lamella clarifiers can handle larger volumes of water with lower operational costs, making them a financially viable option for municipalities and industries seeking reliable water treatment solutions.

Lamella clarifiers are becoming increasingly vital in modern water treatment facilities due to their efficient and compact design, allowing for high flow rates and effective sedimentation. To maintain optimal performance, it is crucial to adhere to best practices for operation and maintenance. According to a report from the Water Environment Federation, the cleaning and maintenance of lamella plates should occur at regular intervals, usually every six months, to prevent the build-up of sludge and ensure effective solids removal. Neglecting this can lead to a decrease in treatment efficiency, with studies indicating that poorly maintained systems can lose up to 30% of their intended capacity.

Regular monitoring of flow rates and sedimentation patterns is also essential. Operators should establish baseline performance metrics to detect deviations early. Data from the American Society of Civil Engineers reveals that maintaining an optimal hydraulic loading rate—typically between 5 to 15 m³/m²/day—can significantly enhance the system's efficiency. Additionally, employing automated monitoring technologies can facilitate real-time assessments of clarifier performance, allowing for immediate adjustments and minimizing downtime. By following these best practices, water treatment facilities can ensure that their lamella clarifiers operate at peak efficiency, ultimately resulting in better water quality and reduced operational costs.

| Aspect | Description | Best Practice |

|---|---|---|

| Design | Proper sizing and configuration of lamella plates to enhance efficiency. | Conduct a hydraulic analysis to determine optimal plate spacing. |

| Influent Quality | Understanding water characteristics like turbidity and contaminant types. | Regularly test and monitor influent parameters. |

| Flow Rate | Maintaining an optimal flow rate to prevent overloading the system. | Implement flow control measures to maintain steady flow. |

| Maintenance | Regular inspection and cleaning of lamella plates. | Establish a routine maintenance schedule based on operational feedback. |

| Sludge Management | Effective handling of sludge produced during the clarification process. | Optimize sludge removal frequency to maintain performance. |

| Training | Training operators to understand system dynamics and troubleshooting. | Conduct regular training sessions and update on new technologies. |

When utilizing a lamella clarifier for water treatment, several common challenges can arise, significantly impacting its efficiency. One of the primary issues is the accumulation of sludge, which can reduce the clarifier's performance. According to a report by the Water Environment Federation, over 30% of systems struggle with improper sludge management, leading to increased operational costs and reduced water quality. Regular monitoring and automated sludge removal systems can alleviate this challenge, ensuring optimal flow rates and clarifier performance.

Another frequent challenge involves the design and layout of the lamella plates themselves. Poorly designed systems can lead to uneven flow distribution, causing turbulence that disrupts sedimentation. A study by the International Water Association highlighted that up to 40% of lamella installations experience flow maldistribution, which compromises treatment efficacy. Implementing computational fluid dynamics (CFD) simulations during the design phase can provide insights into potential flow issues, enabling engineers to optimize the configuration for better performance.

Lastly, the adaptability of a lamella clarifier to varying water qualities poses challenges. Fluctuations in influent characteristics require frequent adjustments in operating parameters. Reports indicate that adaptive operational strategies can enhance performance by 20-30% in response to changing conditions. Training operators to understand these dynamics and utilizing advanced monitoring techniques can facilitate more responsive adjustments and maintain water treatment efficacy.

Innovative technologies are crucial for enhancing the performance of lamella clarifiers in water treatment processes. Recent advancements in materials and design have significantly improved the efficiency of these systems. For instance, the introduction of high-efficiency sedimentation media and advanced flow distribution systems helps optimize the settling rate of particulates. These innovations allow for greater surface area and better hydraulic characteristics, which lead to improved clarity of treated water.

Moreover, integrating automation and monitoring technologies into lamella clarifiers can greatly enhance operational efficiency. Real-time monitoring systems enable operators to adjust parameters dynamically, ensuring optimal performance under varying influent conditions. This level of automation not only aids in consistent water quality but also reduces labor costs and operational complexities. As the demand for efficient water treatment solutions continues to rise, these innovative technologies will play a pivotal role in maximizing the capabilities of lamella clarifiers.