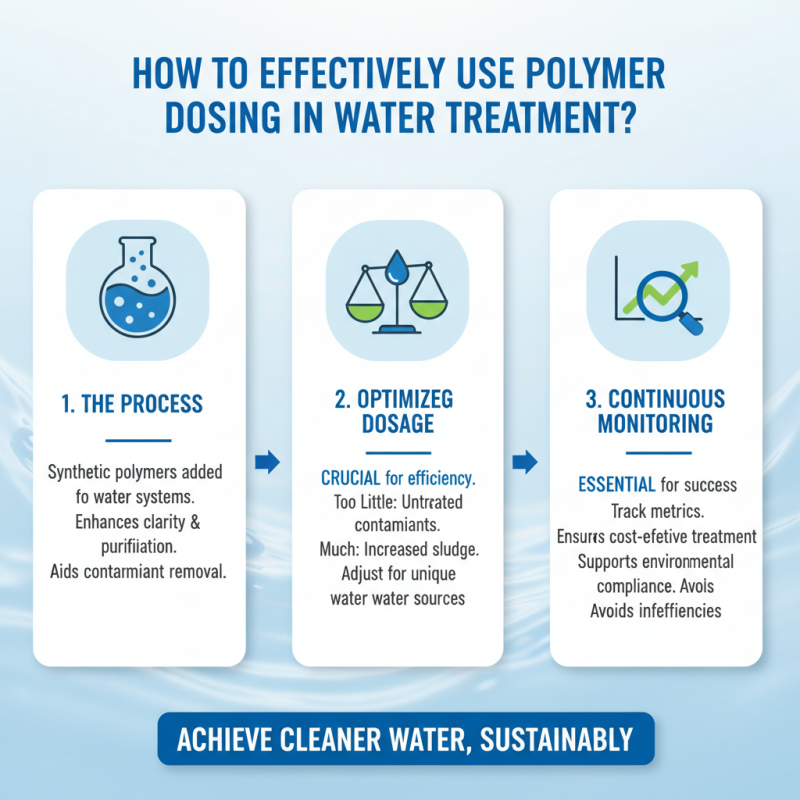

Water treatment processes rely on effective solutions to enhance clarity and enable purification. One critical method is Polymer Dosing. This technique involves adding synthetic polymers to water systems to aid in contaminant removal. It plays a pivotal role in municipal and industrial wastewater treatment.

Implementing Polymer Dosing can be complex. Achieving the right dosage is crucial to maximize efficiency. Too little may leave contaminants untreated; too much can cause other issues, like increased sludge volume. Each water source presents unique challenges, emphasizing the need for adjustment.

Many operators still overlook the importance of monitoring Polymer Dosing levels. Neglecting to track these metrics can lead to operational inefficiencies. Water treatment facilities must continuously evaluate their polymer use. This ensures both cost-effective treatment and environmental compliance. Understanding the nuances of Polymer Dosing is essential for successful water treatment outcomes.

Polymer dosing is a critical aspect of water treatment processes. It involves injecting polymers to enhance the removal of contaminants from water. Understanding how to effectively use polymer dosing can significantly improve treatment efficiency. Polymers are often used as coagulants or flocculants. They help suspend particles to form larger aggregates, making them easier to filter out.

When using polymer dosing, it’s essential to fine-tune the dosage. An excessive amount can cause more harm than good. It might lead to poor separation of solids or even introduce unwanted residues. Begin with a small dose and monitor the changes in water quality. Adjust as necessary.

Tip: Always conduct jar tests in a lab setting before full-scale implementation. This helps predict how different polymers will behave. Document results to refine your approach. Additionally, consider the water characteristics. Turbidity, pH, and temperature can affect polymer performance.

Remember, polymer dosing is not a one-size-fits-all solution. What works for one situation may not work for another. Continuous monitoring is crucial for optimizing performance and minimizing waste. Implementing a flexible dosing strategy can lead to better treatment outcomes while saving costs.

In water treatment, polymers play a crucial role. They enhance coagulation, flocculation, and sedimentation processes. Various types of polymers are utilized, each suited for specific applications. Anionic polymers are widely used due to their effectiveness in treating wastewater. They help reduce suspended solids. Cationic polymers, on the other hand, are effective in dewatering processes. They bind with negatively charged particles to improve efficiency.

Polymer selection is essential based on the water's characteristics. The American Water Works Association reported that improperly chosen polymers can lead to increased operational costs. For example, using the wrong type can result in inefficient floc formation. This can cause higher turbidity levels. Additionally, excessive polymer dosage can hinder treatment instead of enhancing it. The goal is to find a balance that ensures optimal performance without throwing resources away.

Recent studies indicate that non-ionic polymers are gaining traction. They offer versatility for various water qualities. However, there's still much to learn about their long-term effects. Continuous monitoring is necessary to evaluate their overall impact on treatment processes. Adjustments in polymer dosages based on real-time data remain a challenge for many facilities.

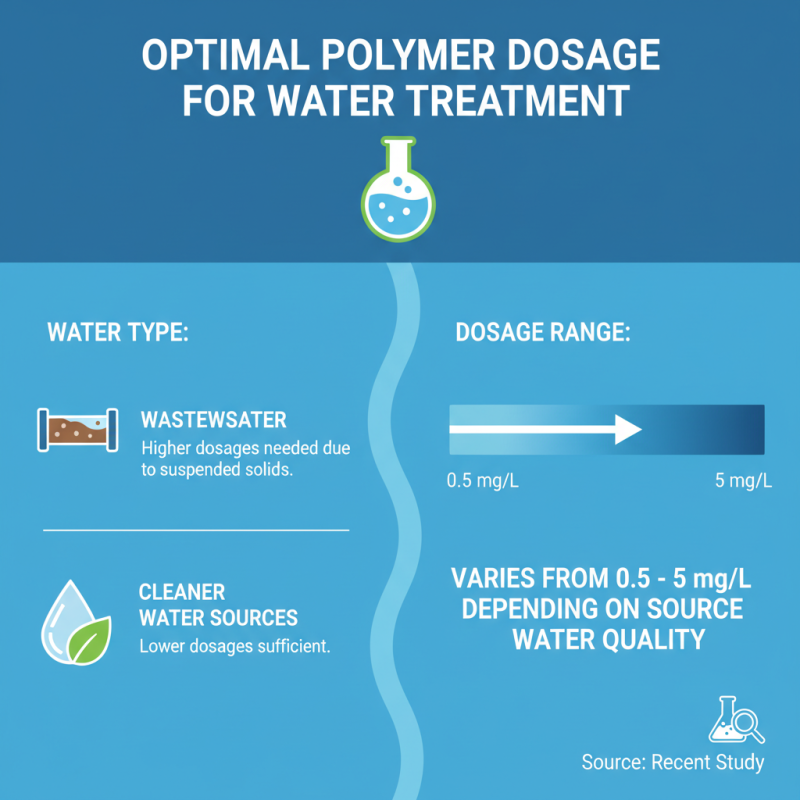

Determining the optimal polymer dosage for water treatment is crucial. Different water types require specific approaches. For example, wastewater may need higher dosages due to suspended solids. According to a recent study, optimal polymer dosage can vary from 0.5 to 5 mg/L depending on the water source.

For surface water, a lower dosage often suffices. Yet, unexpected variations in turbidity can impact performance. A report by the American Water Works Association states that improper dosing may lead to ineffective flocculation, which complicates the purification process. Additionally, overdosing can cause adverse effects, like increased sludge volume.

It's also important to regularly monitor water quality. Changes in pH or temperature can affect polymer efficacy. Operators sometimes overlook these factors, causing inconsistencies. Real-time adjustments facilitate more accurate dosing. This can help achieve better removal rates for contaminants. Thus, a tailored approach is essential for maximizing results in water treatment.

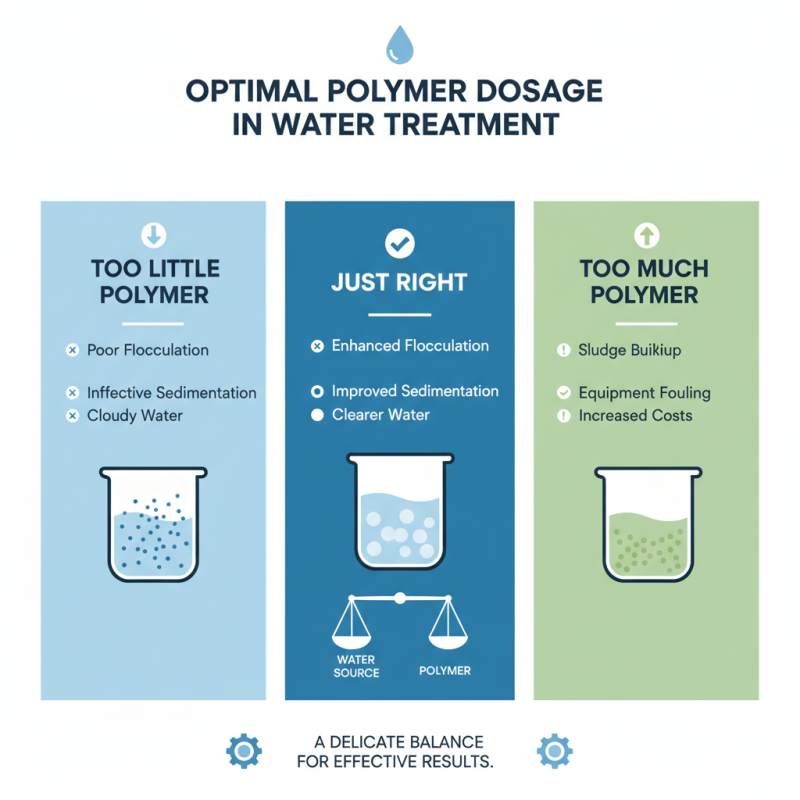

In water treatment, monitoring polymer dosage is essential for effective results. Each water source presents unique challenges. The right amount of polymer can enhance flocculation and improve sedimentation. However, dosing too much may lead to issues like sludge buildup. It’s a delicate balance.

Adjusting polymer dosage requires careful observation. Operators should frequently check clarity and sedimentation rates. Over time, conditions can change, demanding real-time adjustments. Simple testing methods can provide immediate feedback on polymer performance. It’s important to document these changes and outcomes for future reference.

Mistakes can happen. An overestimation in dosing often leads to waste. Conversely, under-dosing may result in ineffective treatment. Operators should reflect on past decisions. What worked? What didn’t? These reflections can inform better practices in the future. Continuous learning is crucial for optimizing polymer use in any treatment setting.

Handling and storing water treatment polymers requires careful attention. Proper storage conditions are vital. Polymers should be kept in a cool, dry place. Avoid direct sunlight, as it can degrade the material. It’s crucial to seal containers tightly to prevent contamination. Regular checking of storage conditions helps ensure polymer effectiveness.

Transportation of these polymers can be challenging. They should be moved securely to avoid spillage. Leaks can create messy situations and waste valuable materials. Ensure that staff is trained on safe handling procedures. Mismanagement in transportation can lead to financial loss and safety issues.

When mixing polymers for use, accuracy matters. Improper ratios can lead to ineffective treatment. Thus, thorough training on dosing techniques is essential. Moreover, maintain records of polymer usage. This practice helps in identifying patterns and potential issues. Facing these challenges allows for ongoing improvement in the process.