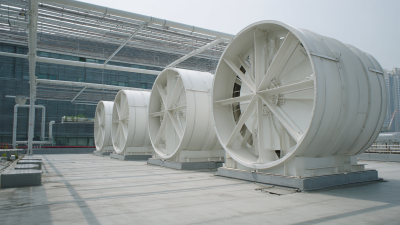

The increasing demand for effective wastewater treatment has led to significant advancements in

aeration technologies, particularly the utilization of Membrane Air Diffusers.

According to the Water Environment Federation, aeration accounts for 50-70% of the total operational costs in wastewater treatment plants,

making efficiency improvements critical for environmental sustainability and economic viability.

Membrane air diffusers offer a robust solution by promoting better oxygen transfer rates and minimizing energy consumption.

Studies have shown that these diffusers can improve oxygen transfer efficiency by up to 30% compared to traditional methods,

leading to enhanced treatment performance. As the global market for wastewater treatment is projected to reach

$615 billion by 2027, investing in innovative aeration systems, such as those utilizing

Membrane Air Diffusers, is paramount for achieving operational excellence

and meeting regulatory requirements.

Membrane air diffusers offer a robust solution by promoting better oxygen transfer rates and minimizing energy consumption.

Studies have shown that these diffusers can improve oxygen transfer efficiency by up to 30% compared to traditional methods,

leading to enhanced treatment performance. As the global market for wastewater treatment is projected to reach

$615 billion by 2027, investing in innovative aeration systems, such as those utilizing

Membrane Air Diffusers, is paramount for achieving operational excellence

and meeting regulatory requirements.

Membrane air diffusers play a crucial role in enhancing the efficiency of aeration systems used in wastewater treatment. By facilitating the fine dispersion of air into the wastewater, these diffusers improve the oxygen transfer rate, which is essential for the effective breakdown of organic matter by microorganisms. According to a report from the Water Environment Federation, the use of membrane diffusers can enhance oxygen transfer efficiency by 20-40% compared to traditional methods. This efficiency not only accelerates the biological degradation process but also reduces overall energy consumption in aeration systems.

Furthermore, membrane air diffusers contribute significantly to the operational cost-effectiveness of wastewater treatment facilities. Research indicates that optimizing aeration through the use of these diffusers can lead to a reduction in energy costs by up to 50%, addressing one of the largest operational expenses in wastewater treatment. Additionally, the longevity and reduced maintenance requirements of membrane diffusers, often surpassing 8-10 years, result in lower replacement costs and less downtime, ultimately leading to more efficient plant operations. As the industry continues to focus on sustainability and efficiency, the adoption of membrane air diffusers is increasingly recognized as a key strategy in modern wastewater treatment processes.

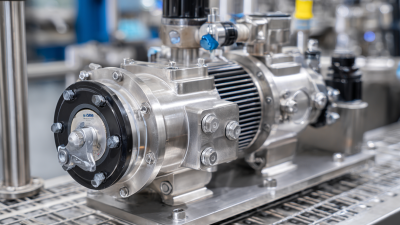

Aeration performance in wastewater treatment systems is significantly influenced by multiple key factors, including the design and operation of membrane air diffusers. The type of membrane material used impacts the efficiency of oxygen transfer to the water, affecting the overall performance of the aeration system. Larger pore sizes may enhance air flow but can reduce the contact time of air with wastewater, thereby limiting oxygen diffusion. Conversely, finer membranes can achieve higher oxygen transfer rates but may result in clogging, which hampers operational efficiency.

Furthermore, the air supply rate and pressure play critical roles in optimizing aeration processes. Proper management of these parameters ensures that the diffusers operate within their optimal range, enhancing oxygen availability for aerobic microorganisms. A balanced approach to air flow not only sustains the required dissolved oxygen levels but also minimizes energy consumption, contributing to a more efficient treatment process. Additionally, regular maintenance of diffusers will reduce fouling and prolong their lifespan, further improving aeration performance and, consequently, the overall treatment efficiency of the system.

When it comes to maintaining membrane air diffusers in aeration systems, regular upkeep is essential for maximizing their longevity and efficiency. One key tip is to perform routine inspections to identify any potential build-up of dirt or biofilm. Cleaning these components not only ensures optimal gas transfer but also extends the life of the diffuser.

Another important aspect of membrane diffuser maintenance is monitoring the aeration system’s pressure. Keeping fluid pressure within recommended levels can prevent excessive strain on the membranes. Additionally, using pre-treatment methods can help minimize solids entering the system, further preserving the integrity of the diffusers.

Lastly, it’s advisable to establish a regular replacement schedule based on the specific operating conditions and water chemistry involved. Keeping a close track of the wear and tear can help anticipate when a diffuser will need replacement, thereby maintaining continuous performance and efficiency in wastewater treatment processes.

Membrane air diffusers are emerging as a superior alternative to traditional aeration methods in wastewater treatment systems. Unlike conventional aeration systems that typically employ mechanical surface aerators or coarse bubble diffusers, membrane diffusers utilize fine bubble technology to enhance the oxygen transfer efficiency. This essential step in the treatment process significantly improves the biological degradation of organic pollutants. The lower energy consumption associated with membrane diffusers also ensures cost-effectiveness, making them increasingly popular in modern wastewater treatment plants.

A comparative analysis reveals that membrane diffusers not only achieve higher oxygen transfer rates but also provide greater operational flexibility. Their design minimizes the risk of clogging and offers consistent performance across varying flow rates. In contrast, traditional methods often require more maintenance due to wear and tear, frequent clogging, and inefficiencies under fluctuating conditions. This highlights the importance of adopting membrane air diffusion technology, as it not only streamlines the aeration process but also reduces the environmental footprint of wastewater treatment facilities.

| Parameter | Membrane Air Diffusers | Traditional Aeration Methods |

|---|---|---|

| Oxygen Transfer Efficiency | > 25% | 15-20% |

| Energy Consumption (kWh/kg O2) | 0.40 | 0.60-0.80 |

| Maintenance Frequency | Low (every 2-3 years) | High (annual) |

| Installation Cost | Moderate | Low |

| Longevity | 10+ years | 5-8 years |

Innovations in membrane technology have significantly transformed wastewater treatment processes, particularly through the use of membrane air diffusers in aeration systems. These diffusers enhance oxygen transfer efficiency, which is critical for aerobic treatment processes. Unlike traditional aeration systems, membrane air diffusers provide fine bubbles that increase the surface area for oxygen absorption, leading to improved microbial activity and faster breakdown of organic materials in wastewater.

Moreover, advancements in membrane materials and designs contribute to reduced energy consumption and lower operational costs. Recent innovations include the development of highly durable and clog-resistant membranes, which prolong the lifespan of the diffusers and minimize maintenance efforts. This not only improves system reliability but also ensures continuous and effective aeration. By integrating these innovative membrane technologies, wastewater treatment facilities can achieve higher treatment efficiency, ultimately leading to better compliance with environmental regulations and a more sustainable approach to water management.