When it comes to maintaining the optimal pH levels in your water systems, choosing the right pH dosing pump is crucial. A pH dosing pump is an essential tool for a variety of applications, from swimming pools and aquariums to industrial processes. The market offers a myriad of options, each with its unique features and specifications, making the selection process overwhelming. In this ultimate guide, we will break down the key factors to consider when choosing a pH dosing pump that best suits your specific needs. Whether you're a homeowner looking to manage your pool's chemistry or a professional in an industrial setting, understanding the functionalities, capacities, and installation requirements of pH dosing pumps will empower you to make an informed decision. Join us as we explore tips, recommendations, and insights to help you navigate the options and select the perfect pH dosing pump for your requirements.

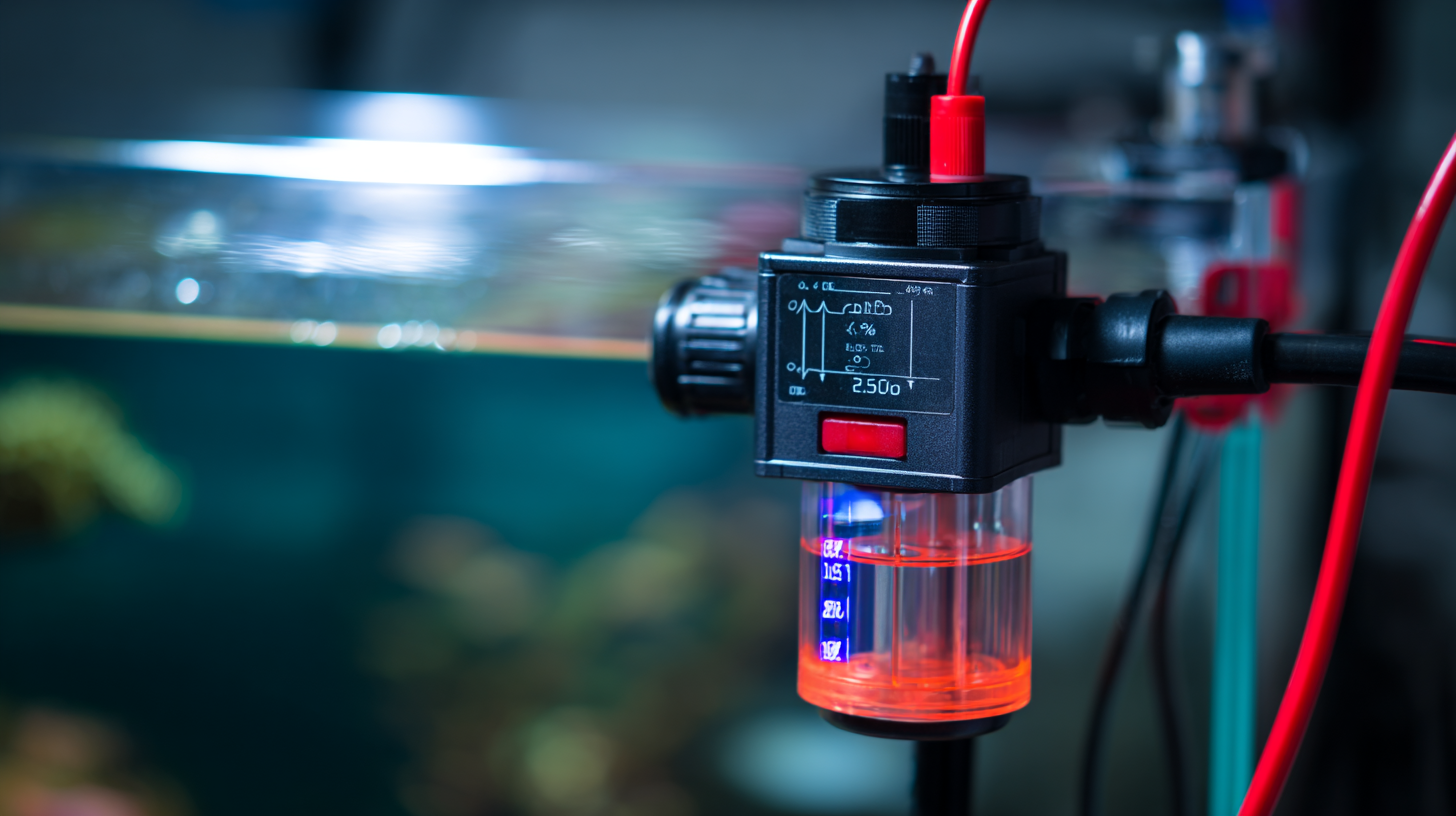

When selecting a pH dosing pump, it’s essential to understand its key features and functions to ensure it meets your specific application needs.

pH dosing pumps play a critical role in controlling the acidity or alkalinity of water in various industries, including agriculture, water treatment, and food processing.

According to a recent industry report by the Water Environment Federation, precise pH control can lead to improved chemical efficiency and enhanced water quality, with optimal dosing achieving accuracy levels within ±0.1 pH units.

When selecting the right pH dosing pump for your system, understanding the various types available can significantly influence operational efficiency. The most common types include diaphragm pumps, peristaltic pumps, and mechanical piston pumps. According to a report by MarketsandMarkets, the global dosing pump market is projected to reach USD 7.3 billion by 2026, with a significant portion attributed to the water treatment and chemical processing industries where precise pH control is crucial.

Diaphragm pumps are ideal for applications requiring high accuracy, as they can handle corrosive liquids without the risk of contamination. They generally offer a flow rate range of 0.2 to 100 GPH and can achieve variations as low as ±1%. In contrast, peristaltic pumps are recognized for their versatility and ease of maintenance, making them suitable for varying flow requirements from 0.1 to 300 GPH. For systems that demand higher pressures, mechanical piston pumps provide robust performance, often utilized in applications where pH levels must be consistently monitored and adjusted. Knowing these distinctions can help ensure you choose the most effective pump for your specific application.

When selecting a pH dosing pump, there are several critical factors to consider to ensure it meets your specific needs.

First, consider the flow rate and capacity of the pump. These specifications are essential to match the volume of your application,

whether it is in water treatment, aquaculture, or industrial processes.

A pump that cannot handle the required flow rate may lead to inadequate treatment, while one that is too large can incur unnecessary costs.

Another important factor is the pump's materials of construction. The materials should be compatible with the chemicals being dosed to

prevent corrosion or degradation over time. Additionally, it’s vital to assess the

control mechanisms available; pumps with advanced technology offer better precision and automation, which can enhance operational efficiency

and reduce human error.

Tips: Always check the manufacturer's specifications and user reviews to gauge reliability and performance. Ensure that the pump you choose is easy to maintain, as

regular upkeep is essential for its longevity. Finally, consider the availability of technical support and warranty options, which can provide peace of mind

in case of any issues.

When it comes to the effective use of pH dosing pumps, proper installation and maintenance are critical components that can significantly influence performance and longevity. According to a report by the American Water Works Association, improper installation can lead to chemical leaks and inefficient dosing, which can compromise water quality. To ensure optimal installation, it is essential to evaluate the layout of your system, select the appropriate pump size, and follow manufacturer guidelines closely. Additionally, securing all connections and calibrating the pump accurately can prevent future operational hiccups.

Regular maintenance is equally vital to keep pH dosing pumps functioning at their best. The National Association of Clean Water Agencies recommends routine checks on pump functionality, including inspecting seals and tubing for wear and tear. Industry studies indicate that pumps maintained on a quarterly schedule can reduce unexpected downtime by up to 30%, enhancing overall system reliability. Utilizing a detailed maintenance log can also help in tracking the performance and lifespan of each component, allowing for timely replacements and adjustments, which ensures continuous and efficient dosing operations.

When it comes to maintaining optimal pH levels in various industrial processes, accurate measurement and control are crucial. According to a 2022 report by the International Society for Automation, improper pH management can lead to inefficiencies costing companies up to 20% of their operational budget. This highlights the importance of investing in reliable pH dosing pumps that not only deliver precise readings but also adjust chemical dosages in real time.

To optimize pH measurement and control, first incorporate regular calibration of your pH sensors. This practice ensures that the data you rely on is accurate, which can significantly enhance process efficiency. Additionally, consider implementing advanced monitoring systems that utilize data analytics for predicting pH variations, allowing for proactive adjustments rather than reactive ones.

Tip: Always choose a pH dosing pump with a fail-safe mechanism. This feature can prevent over-dosing or under-dosing, safeguarding your processes against potential disruptions. Another tip is to regularly assess your chemical inventory and dosing schedule to align with changes in production demands, ensuring your pH levels remain stable and within specified limits.