In the rapidly evolving landscape of water treatment and industrial processes, mastering Polymer Dosing Control has emerged as a pivotal strategy for enhancing operational efficiency and product quality. According to a recent report by MarketsandMarkets, the global polymer market is projected to reach $350 billion by 2026, highlighting the growing reliance on polymers for various applications, including flocculation and sedimentation. However, precise dosing is critical; studies indicate that improper polymer dosage can lead to a 30% increase in operational costs and inefficient sludge management. As industries aim to optimize resource utilization and minimize waste, effective polymer dosing strategies not only ensure compliance with environmental standards but also enhance process reliability. This article will explore ten actionable tips that are essential for mastering Polymer Dosing Control in 2023, ultimately leading to improved performance and sustainability in operations.

Accurate polymer dosing control is vital for optimizing industrial processes, particularly in wastewater treatment, paper production, and mining applications. By ensuring that the correct amount of polymer is used, facilities can enhance flocculation and coagulation processes, leading to improved separation of solids from liquids. This precision not only helps in achieving desired process outcomes but also minimizes chemical usage, resulting in cost savings and reduced environmental impact.

In 2023, the importance of mastering polymer dosing control cannot be overstated. As industries face increasing regulatory pressures and sustainability goals, the ability to consistently deliver the right dosage becomes essential. Advanced technologies, such as real-time monitoring and automated dosing systems, empower operators to respond swiftly to fluctuations in process conditions. Emphasizing the significance of accurate polymer dosing not only aids in operational efficiency but also fosters a culture of responsibility towards environmental stewardship, aligning industry practices with modern ecological demands.

This chart illustrates the dosing efficiency percentage achieved in each quarter of 2023. As evident from the data, polymer dosing control has improved steadily throughout the year, highlighting the importance of accurate dosing in operational efficiency.

In 2023, the manufacturing sector is witnessing a transformative shift in polymer dosing techniques, driven by advancements in technology. Industry reports indicate that smart dosing systems using real-time data analytics can enhance precision by up to 30%, significantly reducing waste and improving product quality. This aligns with the growing demand for efficiency as manufacturers strive to meet increasing production targets while adhering to stringent quality standards. The incorporation of Internet of Things (IoT) devices in polymer dosing systems allows for seamless monitoring and adjustment, ensuring optimal dosing even in complex processes.

Another key innovation is the utilization of artificial intelligence (AI) in polymer dosing control. AI can analyze historical data patterns and predict the necessary adjustments for polymer dosing, optimizing the process without extensive human intervention. According to a recent market analysis, companies that have integrated AI into their dosing systems report a 25% increase in production speed and a marked reduction in errors associated with manual dosing methods. As businesses embrace these key technologies, the future of polymer dosing looks promising, offering increased efficiency and accuracy vital for competitive manufacturing landscapes.

Optimizing polymer dosing efficiency is crucial for achieving the best operational results in various applications, especially in water treatment and industrial processes. One of the best practices is to conduct a thorough analysis of the polymer's characteristics and the specific requirements of the process. Understanding the viscosity, charge density, and molecular weight of the polymer will help in determining the optimal quantity needed for effective dosing. This ensures that the polymer performs at its best without unnecessary overuse, which can lead to higher operational costs and potential negative impacts on the treated effluent.

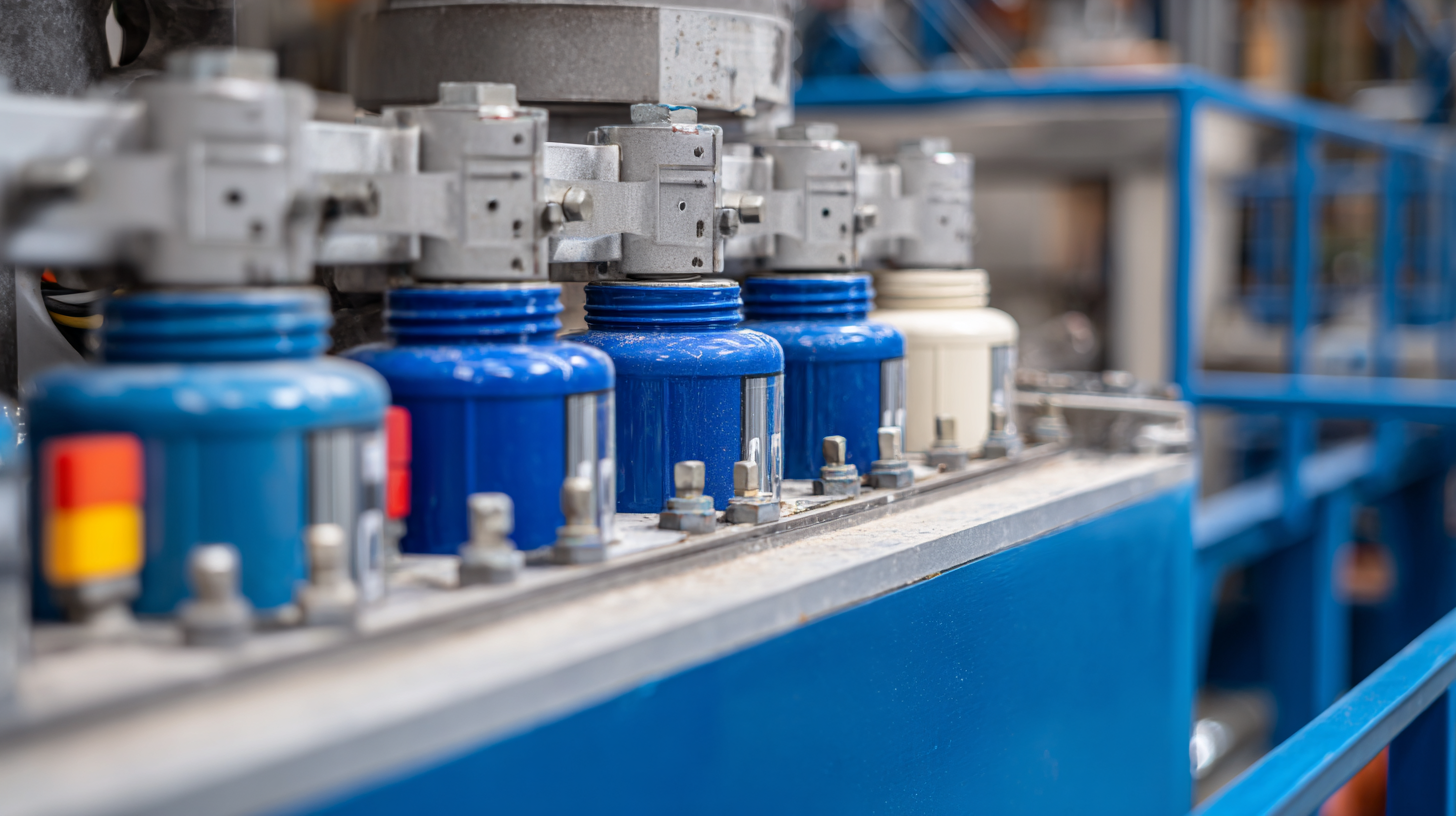

Another key approach is to implement precise metering and monitoring systems. Utilizing advanced technologies such as flow sensors and automated dosing controls enhances the accuracy of the polymer application. By continuously monitoring the results and adjusting the dosage in real-time, operations can maintain optimal performance and efficiency. Regular maintenance of dosing equipment is equally important, as it minimizes downtime and ensures consistent delivery. By adopting these best practices, facilities can maximize polymer performance while reducing waste and costs, leading to a more sustainable and profitable operation.

Polymer dosing control is critical in numerous industries, from water treatment to paper manufacturing. However, companies often face challenges, such as fluctuating inflow rates, inconsistent polymer quality, and varying operational conditions. A recent report from Frost & Sullivan highlights that a staggering 40% of polymer dosing systems suffer from inefficiencies due to these factors, leading to increased operational costs and suboptimal product quality.

One effective strategy to overcome these challenges is implementing real-time monitoring systems. By leveraging advanced sensors and data analytics, facilities can adjust dosing rates swiftly in response to changes in inflow and polymer properties. Additionally, conducting regular training sessions for staff can significantly improve dosing practices. According to a survey by the American Water Works Association, companies that invest in employee training see a 30% increase in the accuracy of polymer dosing operations.

Furthermore, utilizing a centralized dosing control system can streamline operations. This technology not only ensures uniform dosing but also allows for the integration of predictive maintenance, reducing downtime. A study from the Water Environment Federation indicates that such systems can enhance dosing efficiency by up to 25%, translating to substantial cost savings and improved process reliability.

In 2023, the landscape of polymer dosing control is set to transform significantly, influenced by several cutting-edge trends in drug delivery and formulation technologies. One of the most notable advancements is the integration of 3D printing for creating personalized oral dosage forms, which offers a tailored therapeutic approach for patients with mental and neurological disorders. This paradigm shift not only enhances patient adherence but also opens new avenues for the development of complex drug delivery systems specifically designed for diseases like Alzheimer’s, where conventional therapies often fall short.

Moreover, the rise of artificial intelligence in pharmaceuticals is reshaping drug discovery and manufacturing processes, making it possible to optimize polymer formulations more efficiently. AI-driven technologies can analyze vast data sets to predict how different polymers will perform as drug carriers, enhancing both efficacy and safety. Additionally, the use of nanotechnology in drug delivery systems promises to push the boundaries of traditional polymer applications, allowing for targeted therapy that improves treatment outcomes for chronic diseases. As the industry forges ahead, these innovations reflect a promising future for polymer dosing control, marking the beginning of a new era in precision medicine.

| Tip Number | Tip Description | Expected Outcome | Implementation Difficulty |

|---|---|---|---|

| 1 | Optimize dosing strategy with real-time data. | Improved accuracy and efficiency in dosing. | Medium |

| 2 | Implement automated controls to reduce human error. | Increased consistency in performance. | High |

| 3 | Conduct regular maintenance on dosing equipment. | Minimized downtime and improved reliability. | Low |

| 4 | Train staff on polymer dosing best practices. | Enhanced knowledge and skill set of personnel. | Medium |

| 5 | Monitor environmental factors that affect dosing. | Better decision-making during dosing operations. | Medium |

| 6 | Utilize simulation software for optimal dosing. | Informed strategies based on predictive modeling. | High |

| 7 | Analyze historical data for continuous improvement. | Identified trends and areas for optimization. | Low |

| 8 | Experiment with different polymer types and formulations. | Possible cost reductions and performance enhancements. | Medium |

| 9 | Collaborate with suppliers for the latest dosing technologies. | Enhanced access to innovative solutions. | Medium |

| 10 | Regularly review and update dosing protocols. | Ensured practices remain competitive and compliant. | Medium |