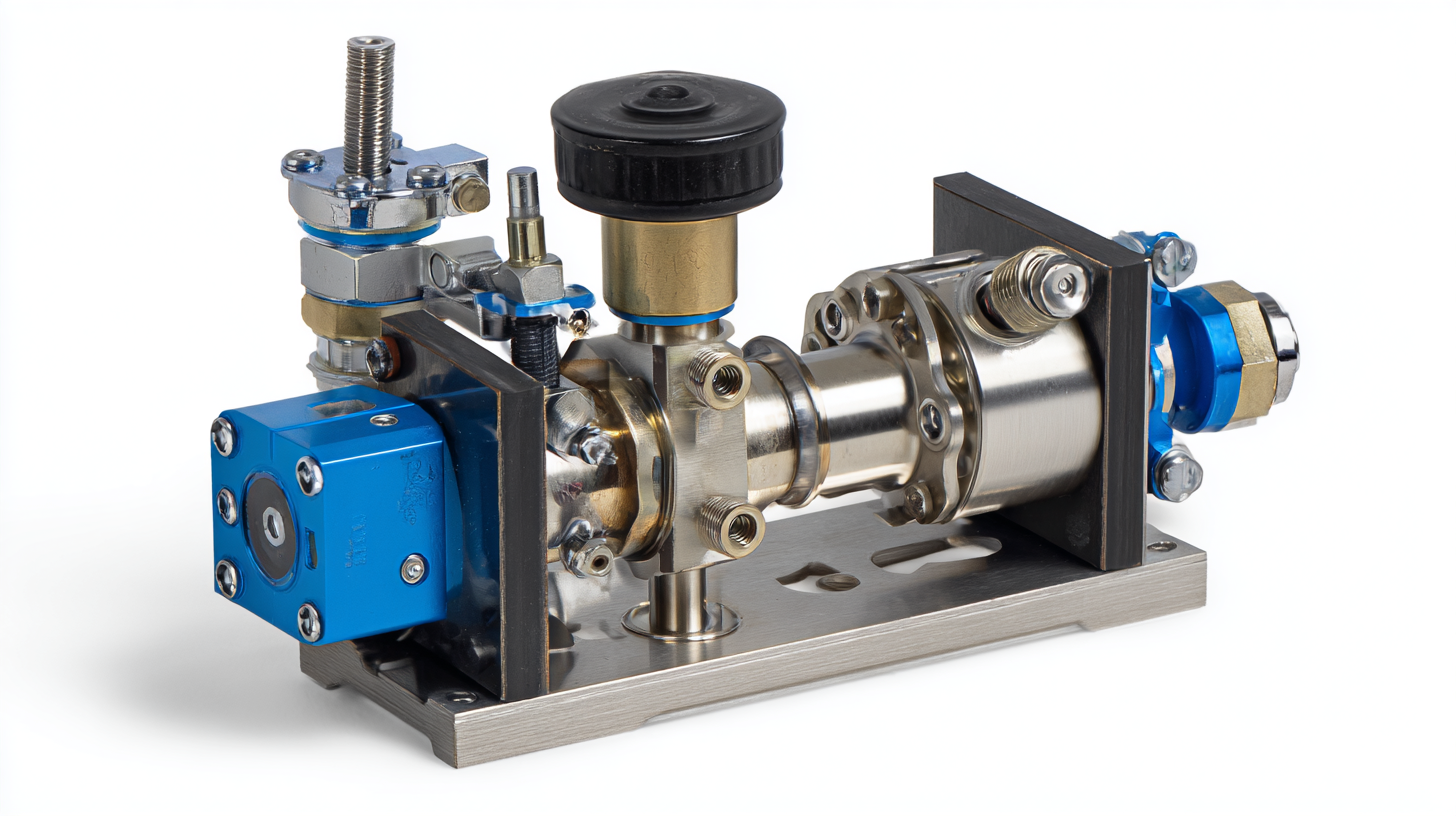

In today's rapidly evolving industrial landscape, maximizing efficiency and minimizing costs are paramount for businesses striving to maintain a competitive edge. The role of precision in fluid management has become increasingly critical, with the global dosing pump market projected to reach $6 billion by 2026, growing at a CAGR of 5.2% from 2021. Among the various solutions available, the Mini Dosing Pump stands out for its compact design, versatility, and ability to deliver precise dosing of various fluids, from chemicals to pharmaceuticals.

As industries embrace automation and seek to optimize their operational processes, the demand for Mini Dosing Pumps is expected to surge, underlining the necessity for reliable after-sales support to ensure continuity and performance. This article explores how investing in the best Mini Dosing Pump, complemented by exceptional customer support, can drive efficiency and innovation, ultimately shaping the future of fluid handling across diverse sectors.

When it comes to maximizing efficiency in fluid management systems, choosing the right mini dosing pump is crucial. According to a recent report by Markets and Markets, the global peristaltic pump market size is expected to reach $2.6 billion by 2025, growing at a CAGR of 6.8%. This growth indicates a surging demand for precise dosing and handling of various fluids across industries such as pharmaceuticals, food and beverage, and water treatment. A well-selected mini dosing pump not only enhances measurement accuracy but also contributes to significant reductions in waste and operational costs.

The importance of efficiency cannot be overstated when selecting a mini dosing pump. For instance, a study by TechSci Research highlights that precision in dosing can lead to a 20% increase in production efficiency, directly impacting a company’s bottom line. Additionally, many modern mini dosing pumps are designed with user-friendly interfaces and advanced control systems that offer real-time monitoring and adjustments, further enhancing operational efficiency. Therefore, investing in a high-quality mini dosing pump tailored to specific application needs, along with unmatched after-sales support, is essential for achieving long-term operational success.

| Pump Model | Flow Rate (L/h) | Power Supply (V) | Max Pressure (Bar) | Material | After Sales Support |

|---|---|---|---|---|---|

| Model A | 5 | 230 | 10 | Polypropylene | 24/7 Support |

| Model B | 10 | 110 | 8 | Stainless Steel | Next Day Response |

| Model C | 15 | 230 | 12 | PVC | Email Support |

| Model D | 20 | 220 | 15 | Aluminum | Phone Support |

| Model E | 8 | 120 | 9 | Nylon | Comprehensive Warranty |

When selecting a high-quality mini dosing pump, key features play a crucial role in maximizing efficiency and operational reliability. One of the primary aspects to consider is the pump's accuracy and precision. According to a report by the Global Pump Market Analysis, advanced mini dosing pumps can achieve dosing accuracy of ±1%, which significantly reduces chemical overuse and waste—an essential factor in industries such as agriculture and water treatment, where every drop counts.

Another important feature is the pump’s compatibility with various media. High-quality mini dosing pumps are designed to handle a wide range of chemicals and liquids, ensuring versatility across applications. A 2023 study from the Chemical Processing Association highlighted that pumps capable of handling corrosive substances have seen a 15% increase in demand due to the rise in stringent industrial regulations. Furthermore, built-in safety features and robust after-sales support from manufacturers are increasingly being highlighted as essential criteria, as they ensure long-term performance and user satisfaction. With effective after-sales support, businesses can minimize downtime and ensure efficient operation, thus enhancing overall productivity.

After-sales support plays a crucial role in the operational efficiency of industries relying on dosing pumps. According to a report by Market Research Future, the global dosing pump market is expected to grow at a CAGR of 5% from 2021 to 2027, highlighting the increasing demand for reliable pumping solutions. However, the effectiveness of these systems relies not just on their initial performance but also on the support they receive afterward. Companies that invest in robust after-sales services often report a 20% improvement in operational uptime, as timely maintenance and expert guidance can prevent costly downtimes.

Furthermore, a study by Technavio indicates that about 70% of customers prioritize after-sales support when choosing a supplier. This insight emphasizes the need for manufacturers of mini dosing pumps to not only deliver high-quality products but also provide unmatched customer support. Those who excel in after-sales services can build long-term relationships with clients, fostering trust and loyalty, which ultimately contributes to better operational outcomes. With efficient resolution of issues and ongoing support, businesses can optimize their processes and significantly enhance productivity.

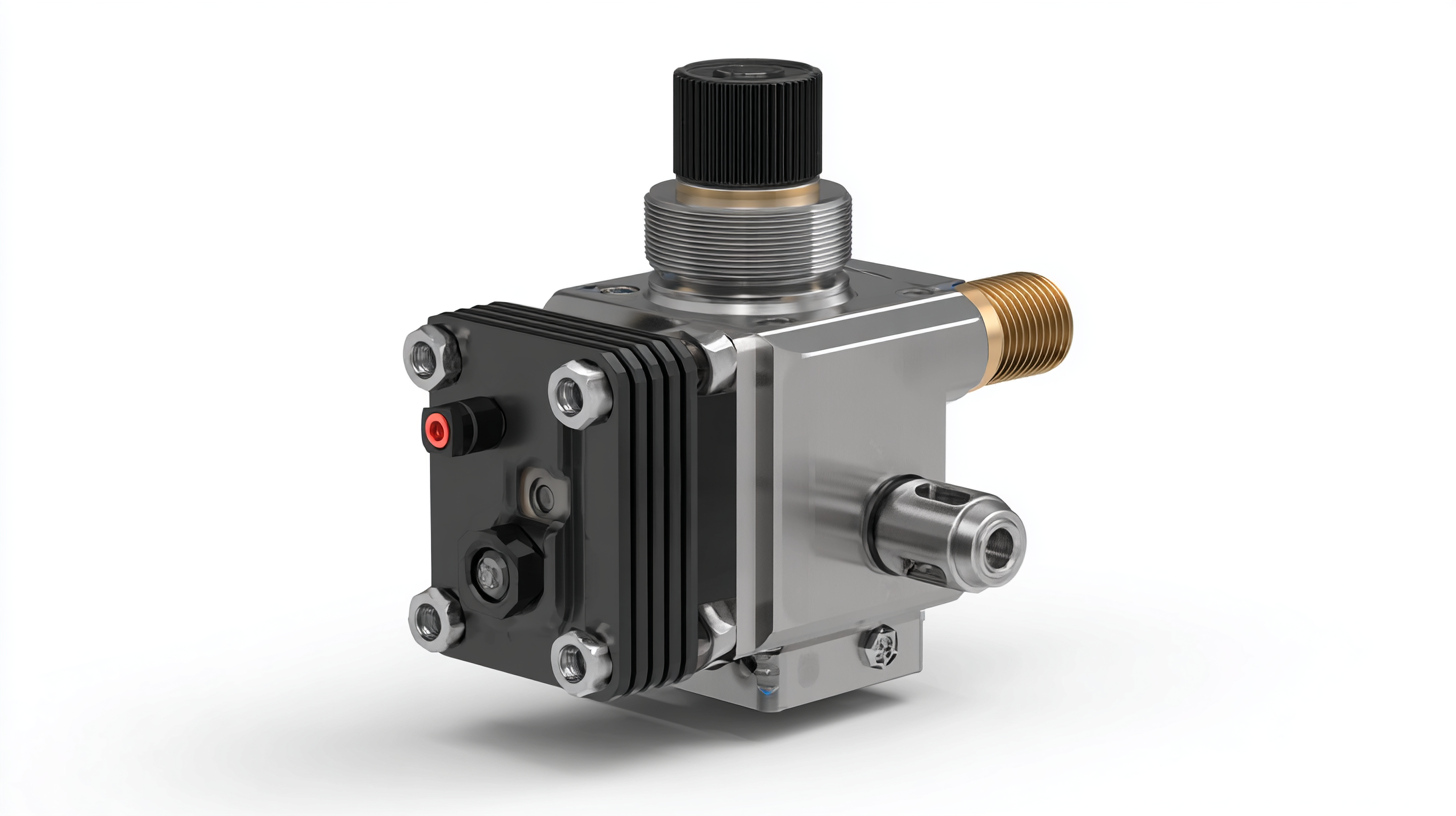

As we look towards 2025, the landscape of mini dosing pump technology is poised for transformative changes. With advancements in materials and digital integration, manufacturers are focusing on creating more efficient and reliable pumping systems. Expect to see greater energy efficiency, which will not only lower operational costs but also contribute to environmental sustainability. Moreover, the integration of smart technology will allow for real-time monitoring and adjustments, empowering operators to optimize performance and streamline processes.

Tip: When selecting a mini dosing pump, consider the pump's material compatibility with the fluids you intend to use. This will enhance durability and prevent costly leaks or failures that could disrupt operations.

Another significant trend is the rise of customizability in mini dosing pumps. As industries demand more tailored solutions, manufacturers are becoming more adept at providing pumps that can cater to specific application needs, whether it's for pharmaceuticals, food and beverage, or chemical processing. This level of customization can greatly enhance efficiency and minimize waste.

Tip: Always consult with your supplier about the potential for customization. This ensures that you're getting a pump best suited for your unique application, maximizing both efficacy and efficiency.

In the competitive landscape of industrial applications, the integration of mini dosing pumps has showcased remarkable successes. Case studies highlight how one manufacturing plant improved its production line efficiency by implementing a state-of-the-art mini dosing pump system. This upgrade not only minimized chemical wastage but also enhanced the precision of ingredient measurements, resulting in consistently high-quality output. The transition was facilitated by comprehensive training and robust after-sales support, which ensured that operators were well-equipped to manage and optimize the new system.

Another compelling case involves a wastewater treatment facility that faced challenges with its chemical dosing process. By adopting a mini dosing pump tailored to their specific needs, the facility experienced a 30% reduction in operational costs. The continuous after-sales support provided post-installation allowed the team to troubleshoot effectively and implement further optimizations over time. Customer feedback highlighted the responsiveness of the support team and the ease of integration, underscoring the importance of both equipment quality and ongoing service in achieving operational excellence.