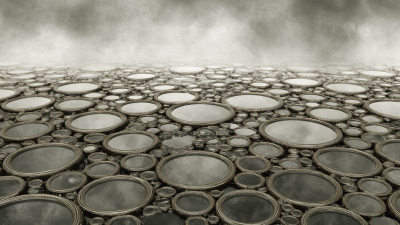

In the realm of aquaculture and wastewater treatment, the Membrane Air Diffuser stands out. These devices play a crucial role in enhancing oxygen transfer efficiency. They are essential for maintaining healthy aquatic environments. With their unique design, these diffusers optimize air distribution. This leads to better aeration across systems.

The benefits of Membrane Air Diffusers extend beyond just oxygenation. They can significantly reduce operational costs and energy consumption. Their durability means they require less frequent replacement, which can save time and resources. Additionally, they minimize maintenance needs, but some users may struggle with initial installation.

For many, the transition to Membrane Air Diffusers raises questions. How do they perform compared to traditional ones? Are they worth the investment? Understanding these aspects can guide better decisions. Exploring the top benefits and uses helps to uncover the true potential behind this technology.

Membrane air diffusers play a vital role in wastewater treatment. These devices release fine bubbles into the water, enhancing oxygen transfer efficiency. According to a report by the Water Environment Federation, membrane diffusers can boost oxygen transfer rates up to 30% compared to traditional systems. This increase in efficiency leads to improved treatment performance.

The use of membrane air diffusers is not limited to just efficiency. They also reduce energy consumption significantly. A study by the Journal of Environmental Engineering found that systems utilizing membrane diffusers consume up to 20% less energy. This reduction can result in substantial cost savings for wastewater treatment facilities, especially as energy prices rise.

However, challenges exist. Membrane diffusers require regular maintenance to prevent fouling. This maintenance can be time-consuming and costly, possibly offsetting some benefits. Additionally, the initial investment for installation can be high. Facilities must weigh these factors when considering membrane diffusers for their operations.

Membrane air diffusers have revolutionized aeration systems. Their efficiency has seen a notable improvement in various applications. Recent studies indicate that these diffusers can enhance oxygen transfer efficiency by up to 30%. This translates to cost savings for treatment facilities, allowing for reduced energy consumption.

In practical terms, membrane diffusers utilize small bubbles. This feature promotes better gas exchange than traditional methods. Reports suggest that facilities adopting membrane diffusers have experienced a significant decrease in operational costs. Approximately 15-20% of energy savings are achieved. This is a considerable number when looking at annual budgets.

However, not all installations achieve optimal performance. System design and maintenance play crucial roles. Poor installations can lead to uneven airflow, reducing efficiency. Regular maintenance is often neglected, resulting in reduced lifespan and efficiency of the diffusers. Facilities should reflect on processes to ensure maximum output from their aeration systems. Striking a balance between cost and performance is essential for long-term success.

When considering the cost-effectiveness of membrane air diffusers, the figures tell a compelling story. Research indicates that membrane air diffusers can reduce energy consumption by up to 30% compared to traditional methods. This reduction can significantly cut operating costs, especially in large-scale wastewater treatment facilities. The initial investment may be higher, but the long-term savings are notable. For instance, studies show that membrane diffusers can last up to five years longer than their traditional counterparts, further enhancing their overall value.

Tips: Always evaluate local energy prices. Savings can vary based on region.

Operating efficiency is another crucial aspect. Membrane air diffusers provide finer bubbles, enhancing oxygen transfer rates. This results in a more efficient aeration process. In some cases, the improved performance can lead to a reduction in the required aeration time, saving both energy and costs. However, regular maintenance is essential. Overlooking this can negate cost savings.

Tips: Schedule routine inspections to maintain efficiency.

While the advantages are clear, some users report challenges. Installation and integration can be complex. Not all facilities are equipped for the transition. It’s vital to assess your existing systems before switching to membrane diffusers. Measuring initial performance can help justify potential changes.

This chart illustrates the cost-effectiveness index of membrane air diffusers compared to traditional air diffusers. A higher index indicates greater cost-effectiveness, demonstrating that membrane air diffusers (80) significantly outperform traditional methods (50) in terms of cost efficiency.

Membrane technology plays a crucial role in enhancing dissolved oxygen (DO) levels in various water treatment processes. It utilizes fine pores to create small bubbles. These bubbles increase the surface area for gas exchange. As a result, more oxygen dissolves into the water. This oxygen is vital for aquatic life and improves water quality.

In many applications, achieving optimal DO levels is a challenge. Traditional methods may not provide enough oxygen, harming organisms. Membrane air diffusers help overcome this issue. They distribute air evenly and efficiently. These diffusers can reduce energy costs as well. Users experience more effective oxygenation, but they may encounter maintenance challenges. Clogging can occur, requiring periodic cleaning.

Despite their advantages, relying solely on membrane technology poses risks. If not properly managed, oxygen levels can fluctuate. Such inconsistencies might lead to stress in aquatic systems. Regular monitoring is essential to maintain balance. Therefore, while membrane air diffusers offer significant benefits, users must also reflect on potential drawbacks and ensure comprehensive management strategies are in place.

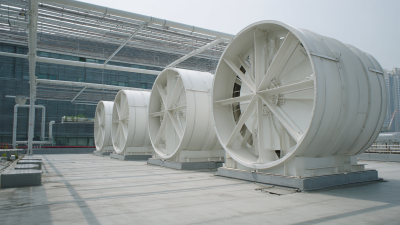

Membrane air diffusers play a crucial role in various industries. They effectively introduce air into liquids, promoting aeration and circulation. In wastewater treatment plants, these diffusers improve oxygen transfer efficiency. This is vital for the biological processes that break down organic waste.

In aquaculture, membrane diffusers help maintain optimal conditions for fish and other aquatic life. Aeration ensures a healthy environment, reducing risks of disease. The control over oxygen levels can lead to better growth rates and higher survival rates of fish. A well-managed system is integral to successful farming.

Tip: Regular maintenance of diffusers can prevent clogging, ensuring efficiency. Monitor the performance frequently to identify potential issues.

Pharmaceutical companies also benefit from these diffusers. Accurate air distribution is necessary for certain processes. Any inconsistency can lead to contamination or product loss. Therefore, diligent monitoring is needed.

Tip: Invest in good quality membranes to enhance longevity. Don't overlook small details that can lead to bigger issues later. Regular checks can save costs in the long run.