The Micro Bubble Air Diffuser is increasingly popular in various sectors. This technology improves oxygen transfer in water, crucial for fish farms and aquaculture. It creates tiny bubbles that enhance water aeration. Observations show better growth rates in fish when using these diffusers.

Many users encounter challenges when implementing the Micro Bubble Air Diffuser. Some devices fail to produce consistent bubble sizes, impacting performance. Ensuring proper installation and maintenance can be tricky. Users often report dissatisfaction due to insufficient airflow or clogging issues.

It is essential to optimize the use of the Micro Bubble Air Diffuser for best results. Regular monitoring and adjustments can significantly enhance efficiency. Each system may require unique tweaks to function well. Reflecting on these aspects could lead to better productivity and satisfaction.

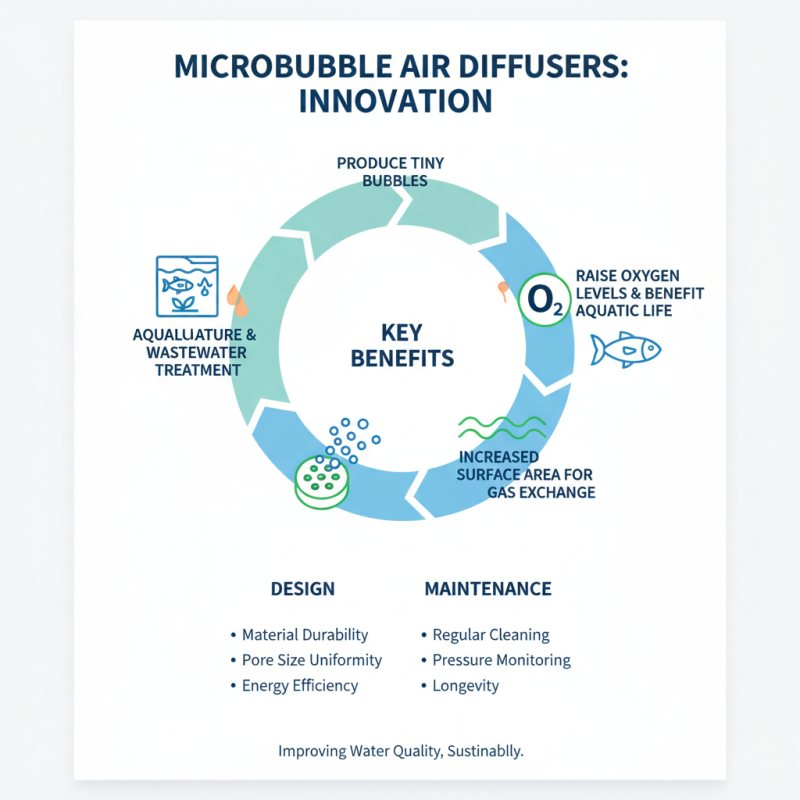

Micro bubble air diffusers are an innovative solution in various applications, from aquaculture to wastewater treatment. These systems produce tiny bubbles, significantly increasing surface area for gas exchange. As a result, oxygen levels can rise, benefiting aquatic life. The effectiveness of these diffusers relies heavily on their design and maintenance.

Proper functionality begins with understanding the anatomy of the diffuser. The material, size, and distribution of pores play crucial roles in bubble generation. Larger pores often produce fewer bubbles but with more volume. Conversely, smaller pores create numerous tiny bubbles, enhancing oxygen transfer. However, it can be frustrating when clogs occur due to organic buildup. Regular cleaning is essential, yet many neglect this aspect.

Another factor to consider is the installation depth of the diffuser. It should be placed in a way that maximizes bubble rise without excessive energy use. Users sometimes overlook the distance to the water surface, leading to inefficient oxygenation. Balancing these elements can be tricky, but it's vital for achieving optimal performance. Awareness of these issues can lead to better decision-making and improved outcomes in various settings.

Micro bubble air diffusers have gained significant attention in various industries. Their unique design allows for the production of tiny bubbles, typically less than 50 microns in diameter. According to recent industry reports, these micro bubbles enhance oxygen transfer efficiency by up to 90%. This efficiency is crucial in aquaculture systems, where optimal oxygen levels are needed.

Key features of micro bubble diffusers include their high surface area-to-volume ratio. This characteristic promotes better gas exchange, ultimately benefiting aquatic life. In wastewater treatment, they can improve the removal of pollutants, leading to cleaner effluents. However, not all diffusers work equally well. Factors such as bubble size, distribution, and operating pressure can affect overall performance.

Moreover, the materials used in manufacturing these diffusers play a vital role. Durable and resistant materials can extend the lifespan of the products. Nonetheless, users often overlook maintenance. Neglecting routine checks can lead to inefficient operation. It’s evident that while micro bubble air diffusers offer many advantages, mindful implementation is essential for maximum effectiveness.

Micro bubble air diffusers are essential for enhancing oxygen levels in aquaculture and wastewater treatment. Correct installation can significantly impact their efficiency. Studies show that properly positioned diffusers increase oxygen transfer rates by up to 30%. Depth is crucial. Placing them deeper in the water can lead to better dispersal of bubbles, ensuring maximum contact time with water.

Consider using a grid layout for installation. This helps distribute air evenly. Reports suggest that uneven placement can create dead zones, reducing overall efficiency by as much as 15%. Check for clogs regularly. A build-up of debris can impede airflow. Adjustments in airflow rates might be necessary, based on water conditions. Monitoring is key to maintaining long-term performance.

One common mistake is not accounting for water temperature. Colder water holds more oxygen but requires precise distribution of micro bubbles. Additionally, be mindful of the size and distribution of the bubbles themselves. Smaller bubbles tend to rise more slowly, allowing for better absorption. Regular maintenance and adjustments based on observed performance can lead to improved outcomes.

| Installation Aspect | Best Practice | Expected Outcome |

|---|---|---|

| Location | Install in low water flow areas | Increased diffusion efficiency |

| Depth | Position at optimal depth of 1-3 feet | Maximized bubble retention time |

| Pipe Size | Use appropriate diameter based on flow rate | Optimized air-water contact |

| Air Supply | Maintain constant air supply pressure | Stable bubble production |

| Maintenance | Regularly clean diffusers and replace as needed | Consistent performance over time |

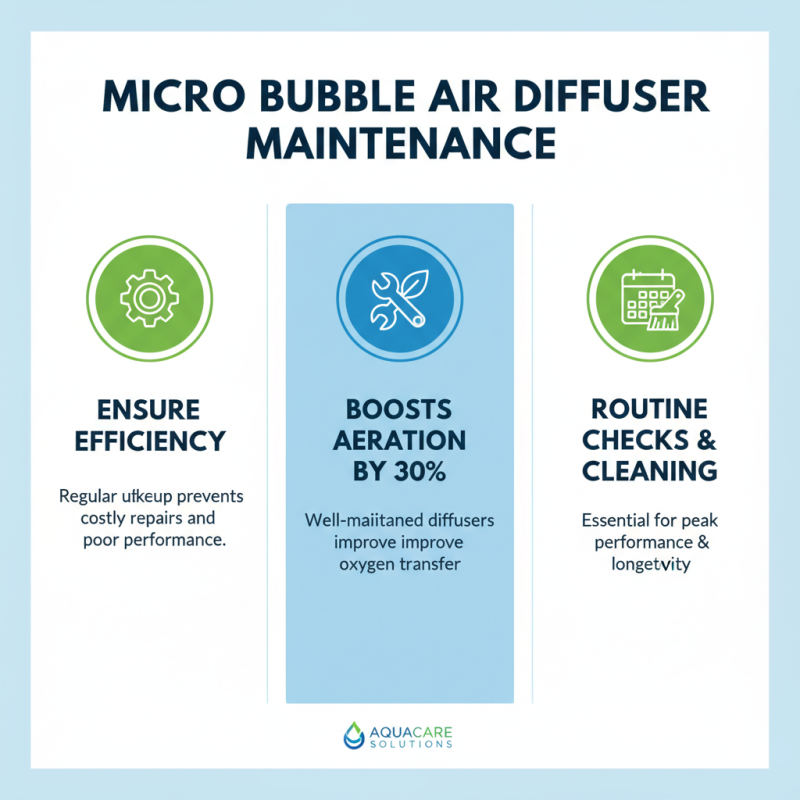

Micro Bubble Air Diffusers require regular maintenance to ensure their efficiency. Proper upkeep can prevent costly repairs and inefficient performance. According to industry studies, well-maintained air diffusers can enhance aeration efficiency by up to 30%. This highlights the importance of regular checks and cleaning.

To maintain optimal function, one effective tip is to inspect the diffuser for blockages. Sediments and algae can build up over time. If these obstructions aren’t removed, they will reduce oxygen transfer rates. Utilizing a soft brush for cleaning can be helpful. Clean diffusers typically operate at a much higher efficiency.

Another vital maintenance task is to monitor air flow rates. If the rate drops below optimal levels, it may indicate a problem. Adjusting the air supply can also revitalize performance. Regularly logging these measurements helps capture trends, leading to better decision-making. Maintaining accurate records can often reveal patterns needing attention.

Neglecting maintenance can lead to unexpected challenges. Small issues can snowball into larger ones if left unattended. A commitment to ongoing check-ups will help avert potential pitfalls.

Micro bubble air diffusers are essential for enhancing water aeration. However, they can encounter several issues affecting performance. One common problem is clogging, which often arises from debris or mineral buildup. Regular cleaning is crucial. Most users neglect this, leading to reduced efficiency. A clogged diffuser can greatly hinder oxygen transfer. Check your diffuser frequently for blockages.

Another issue involves uneven air distribution. This can occur due to improper positioning. Ensure that diffusers are placed at optimal spots for even distribution. Sometimes, users install them too closely together, causing some areas to receive too much air while others receive very little. Experimenting with the layout can help achieve better results.

Noise is another irritating problem. An air diffuser can produce unwanted sounds when operational. This often indicates that air is not flowing smoothly. Reducing pump speed may help, but that can also affect performance. Users often feel stuck between having noise and efficiency. It’s important to balance these factors. Regular checks and adjustments are key to maintaining optimal performance.