The Mini Dosing Pump is set to transform industries by 2026. These small yet powerful devices play a critical role in precise liquid dispensing. Users seek accuracy and efficiency in various applications, from laboratories to manufacturing.

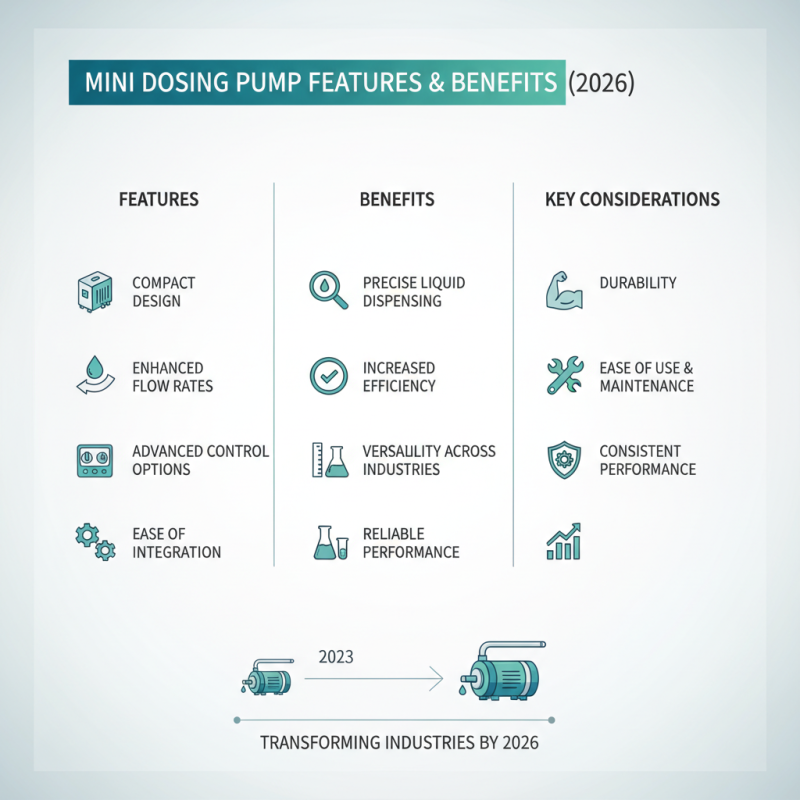

In recent years, the functionality of Mini Dosing Pumps has improved significantly. They're now more compact, making them ideal for limited spaces. These pumps offer better flow rates and advanced control options. Users appreciate the ease of integration into existing systems. However, maintaining consistent performance can still be a challenge.

As industries evolve, the demand for reliable dosing solutions increases. Mini Dosing Pumps respond to this need with their versatility. Still, potential users must consider factors like durability and ease of use. Understanding these pumps is essential for optimizing their benefits. In 2026, Mini Dosing Pumps will be indispensable for many sectors. The journey to perfection is ongoing, and reflection plays a vital role.

Mini dosing pumps are becoming essential in various industries. In 2026, the focus is on efficiency and precision. These pumps are designed for accurate fluid dispensing. They allow for controlled dosing across different applications. This ensures that processes run smoothly without excess waste.

One key feature is the adjustable flow rate. Users can modify the flow to meet specific needs. This flexibility can enhance productivity. Another important aspect is their compact size. This makes mini dosing pumps ideal for spaces where larger pumps cannot fit. However, with their small size, users must ensure proper handling. Overlooked, such care can lead to malfunctions or misuse.

**Tip:** Regular maintenance is crucial. Even small pumps can malfunction if neglected. Also, it’s vital to train personnel on safe operation. This will minimize risk and improve efficiency. Remember to validate the calibration periodically to maintain accuracy.

Mini dosing pumps are gaining traction across various industries. Their compact size makes them versatile, while their precision ensures accurate chemical dosing. These pumps can be found in water treatment, agriculture, and even food processing.

In agriculture, for instance, mini dosing pumps enable precise nutrient delivery. Farmers can supply the exact amount of fertilizers needed. This minimizes waste and enhances crop yields. However, improper calibration can lead to over or under-dosing, which is a common mistake.

Tips: Regular maintenance of these pumps guarantees optimal performance. Check for leaks often. Ensure the settings are correctly adjusted.

In the food industry, safety is paramount. Mini dosing pumps can help automate the addition of flavorings and preservatives. They supply consistent and reproducible doses, which is critical for product quality. Yet, if the dosage is not monitored closely, it might affect taste and consumer satisfaction.

Tips: Train staff to understand the equipment fully. Encourage a culture of checking and double-checking. Accuracy can never be overemphasized.

Mini dosing pumps are evolving rapidly. By 2026, advancements in their technology will transform industries. Enhanced precision and control will be key features. Smaller form factors will allow for seamless integration into existing systems.

Innovations in materials will lead to greater durability. These pumps will handle more aggressive chemicals without wear. Improved user interfaces will simplify operation and increase efficiency. Smart connectivity features may enable real-time monitoring and adjustments. Compact designs will make maintenance easier, though accessibility remains a concern.

While these developments seem promising, challenges abound. Not every pump will meet the diverse needs of users. Over-reliance on smart technology may introduce new risks. Balancing automation with human oversight is crucial. As we move forward, it’s vital to reflect on these issues to ensure the technology serves its intended purpose effectively.

Mini dosing pumps have gained popularity in various sectors. They offer precise control over fluid delivery. Unlike traditional dosing systems, mini pumps are compact and easy to install. Their small size allows for better integration into existing systems. Furthermore, they consume less energy. This translates to reduced operational costs over time.

While mini dosing pumps excel in precision, they may have limitations. For instance, the capacity might be lower than traditional systems. Users must ensure they select the right pump for their specific needs. Maintenance can also be more frequent, which some might view as a drawback. However, the ease of use and automation features make them appealing.

Overall, the transition from traditional to mini dosing systems can enhance efficiency. Users should weigh the pros and cons carefully. It is crucial to understand the operational environment, as this influences pump performance. The benefits often outweigh the challenges, provided the right choices are made.

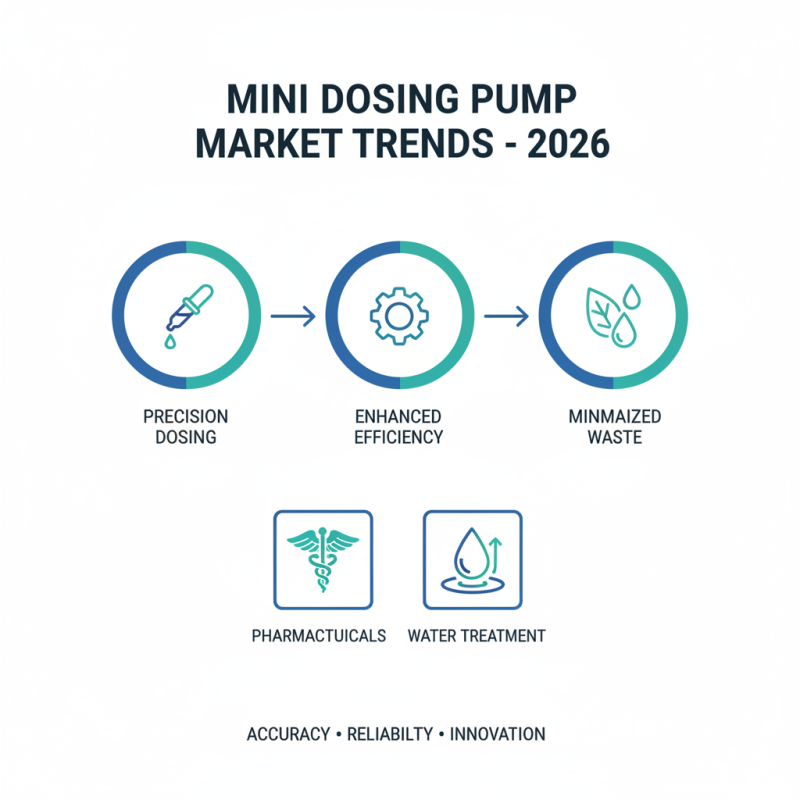

The mini dosing pump market is evolving rapidly. Several trends are shaping the industry in 2026. One significant trend is the increasing demand for precision dosing. Industries are focused on accuracy. This trend enhances efficiency and minimizes waste. Essential for applications like pharmaceuticals and water treatment.

Another key aspect is the growth of automation in manufacturing processes. Companies are integrating smart technology into dosing systems. Automation boosts operational efficiency. It reduces human error, leading to more reliable results. However, this shift raises concerns about training staff to manage sophisticated systems. The need for skilled operators cannot be overlooked.

Sustainability is becoming a priority in pump development. Manufacturers are exploring eco-friendly materials and designs. Consumers are more aware of environmental impacts. They seek products that reduce carbon footprints. Yet, balancing cost with sustainable practices often presents challenges. Finding the right materials may not always be straightforward. The journey towards sustainable mini dosing pumps requires ongoing reflection and adjustment.