In 2023, the precision and efficiency of chemical dosing in various industries rely heavily on the advancements in Mini Max Dosing Pumps. These pumps are not merely auxiliary devices; they are critical for processes where exact fluid measurement is essential. According to a recent industry report by the Fluid Handling Association, the global market for dosing pumps has seen a remarkable growth of 5.5% CAGR, emphasizing the increasing reliance on technology that ensures accuracy and reliability in fluid management.

Dr. Emily Carter, a leading expert in fluid dynamics and the CEO of Pump Innovations, stated, "The evolution of Mini Max Dosing Pumps is setting new standards in operational efficiency, minimizing waste while maximizing precision." These pumps offer unmatched controllability, allowing industries such as water treatment, pharmaceuticals, and food processing to optimize their workflows. As we delve into the top ten Mini Max Dosing Pumps, we aim to highlight their features, applications, and the cutting-edge technologies that are reshaping the landscape of fluid dosing today. By understanding these tools, stakeholders can better navigate the future of chemical dosing, ensuring both environmental and economic sustainability.

Mini Max dosing pumps are essential tools for industries that require precise dosing of liquids, ranging from pharmaceuticals to agriculture. One of the key features that sets these pumps apart is their exceptional accuracy. High-resolution flow control systems allow for precise adjustments in flow rates, ensuring that the correct amount of liquid is dispensed every time. This precision minimizes waste and optimizes chemical usage, resulting in cost savings and improved efficiency for operations.

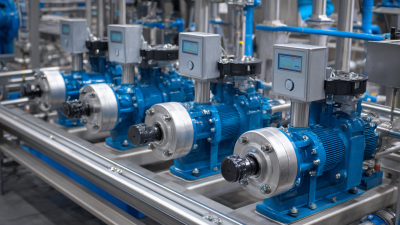

Another significant characteristic of Mini Max dosing pumps is their advanced monitoring capabilities. Many models are equipped with digital displays and connectivity options, enabling real-time tracking of dosing parameters and system performance. This feature not only enhances user control but also aids in troubleshooting and maintenance, allowing operators to respond promptly to any fluctuations. Furthermore, these pumps are designed with materials resistant to corrosion and wear, ensuring long-lasting performance even in demanding environments. Together, these features make Mini Max dosing pumps an ideal choice for those seeking to optimize precision and efficiency in their dosing applications.

When comparing Mini Max dosing pumps to traditional alternatives, it's essential to highlight the efficiency and precision these innovative devices bring to various applications. Mini Max dosing pumps typically feature advanced technology that allows for adjustable flow rates and improved accuracy in chemical dosing. This adaptability means that users can fine-tune the dosage according to specific operational needs, significantly reducing waste and ensuring optimal chemical usage. In contrast, traditional pumps often operate on a fixed system, leading to over- or under-dosing and potentially causing inefficiencies.

Moreover, Mini Max dosing pumps offer energy-saving benefits that traditional alternatives may not provide. Many models are designed with energy-efficient motors and intelligent control systems that minimize power consumption without compromising performance. This results in lower operational costs and a smaller carbon footprint, making Mini Max pumps an environmentally friendly choice. As industries increasingly prioritize sustainability and efficiency, the advantages of Mini Max dosing pumps over conventional systems become even more evident, marking a shift towards smarter and more responsible dosing solutions.

Mini Max dosing pumps are gaining traction across various industries due to their ability to deliver precise fluid measurements with increased efficiency. These pumps are particularly useful in the chemical industry for tasks such as transferring aggressive chemicals safely and accurately. The pharmaceutical sector also benefits from these pumps, as they provide the necessary precision required in drug formulation processes. Furthermore, water treatment facilities utilize Mini Max dosing pumps to ensure consistent chemical dosing, enhancing treatment efficacy.

Tips for optimizing the use of Mini Max dosing pumps include regularly calibrating your equipment to maintain accuracy. Additionally, selecting the right pump material based on the chemical properties being handled can significantly improve durability and performance. It is also essential to monitor pump operation regularly to identify any wear and tear, ensuring continuous efficiency and reliability in your applications.

In food and beverage processing, Mini Max dosing pumps come in handy for accurately adding flavors or preservatives to products. They can also be applied in agriculture, where precise chemical dosing is critical for effective crop protection and nutrition. By leveraging these pumps, industries can enhance their operational efficiency and minimize waste, underlining the growing importance of precision in fluid management.

When considering dosing pumps for 2025, reliability and performance are critical factors that can significantly impact operational efficiency. The top five Mini Max dosing pumps available this year stand out for their innovative technology and highest precision in fluid handling. These pumps are designed to meet the demands of various industries, ranging from pharmaceuticals to water treatment, ensuring they deliver consistent results while minimizing downtime.

**Tips:** When selecting a dosing pump, pay close attention to the materials used in construction to ensure they are compatible with your specific fluids. Additionally, consider the pump's flow rate and pressure capabilities, which should align with your operational requirements for optimal performance. It’s also wise to assess the manufacturer's warranty and support services, as these can be invaluable if technical issues arise.

Another essential aspect to evaluate is the pump's ease of integration and maintenance. Many modern Mini Max dosing pumps are equipped with user-friendly interfaces and innovative designs that simplify routine tasks. Opting for a pump with advanced monitoring features can also help in early detection of potential issues, ensuring continuous, trouble-free operation.

| Model | Flow Rate (L/hr) | Max Pressure (bar) | Precision (%) | Features |

|---|---|---|---|---|

| Model A | 10 | 3 | ±1 | Smart Control, Self-Cleaning |

| Model B | 15 | 4 | ±0.5 | Adjustable Flow, Compact Design |

| Model C | 5 | 2 | ±3 | Low Noise Operation |

| Model D | 20 | 5 | ±1.5 | Remote Monitoring, High Durability |

| Model E | 25 | 6 | ±2 | Energy Efficient, User Friendly |

| Model | Flow Rate (L/hr) | Max Pressure (bar) | Precision (%) | Features |

|---|---|---|---|---|

| Model F | 30 | 7 | ±1 | Advanced Controls, Flexible Operation |

| Model G | 18 | 5 | ±1.5 | High Capacity, Quick Setup |

| Model H | 12 | 3.5 | ±2 | Robust Design, Easy Maintenance |

| Model I | 22 | 6.5 | ±0.8 | Modular System, High Flexibility |

| Model J | 28 | 7 | ±1.2 | State-of-the-Art Technology, User Interface |

The dosing pump market is on the cusp of significant transformation, driven by innovative technologies aimed at enhancing efficiency. Notably, advancements in AI-powered operational intelligence are streamlining processes, allowing for real-time monitoring and optimization of dosing precision. This trend is becoming increasingly vital as industries seek to optimize their operations while minimizing waste. According to a recent report, the global pumps market is projected to grow at a CAGR of 4.9%, reaching USD 100.1 billion by 2035, underscoring the demand for more efficient solutions in both industrial and healthcare applications.

Furthermore, the shift towards sustainable water treatment practices is reshaping dosing pump applications. As the desalinization sector seeks energy-efficient methods, the importance of effective chemical dosing is paramount. The infusion pumps market, anticipated to grow at a CAGR of approximately 10% by 2032, illustrates the pressing need for advanced healthcare solutions that leverage precision dosing technologies. These innovations are not only shaping market dynamics but also facilitating decentralized infrastructure and flood prevention measures, highlighting the critical role dosing pumps play in modern technology landscapes.