Accurate liquid management is essential in various industries. Mini Max Dosing Pumps play a crucial role in achieving this precision. These pumps are designed for efficient dosing, enabling accurate measurement of liquids. However, users often face challenges when utilizing them.

Common issues include incorrect calibration and inconsistent flow rates. This can lead to product waste and costly errors. Users need to be vigilant when setting up these pumps. Regular maintenance is also vital to ensure optimal performance. Moreover, understanding the specifications of Mini Max Dosing Pumps can enhance their effectiveness.

While technology brings solutions, it’s important to remember that it’s not infallible. Users must reflect on their practices. They should regularly assess their dosing systems and identify areas for improvement. This proactive approach will lead to better liquid management and reduced operational risks.

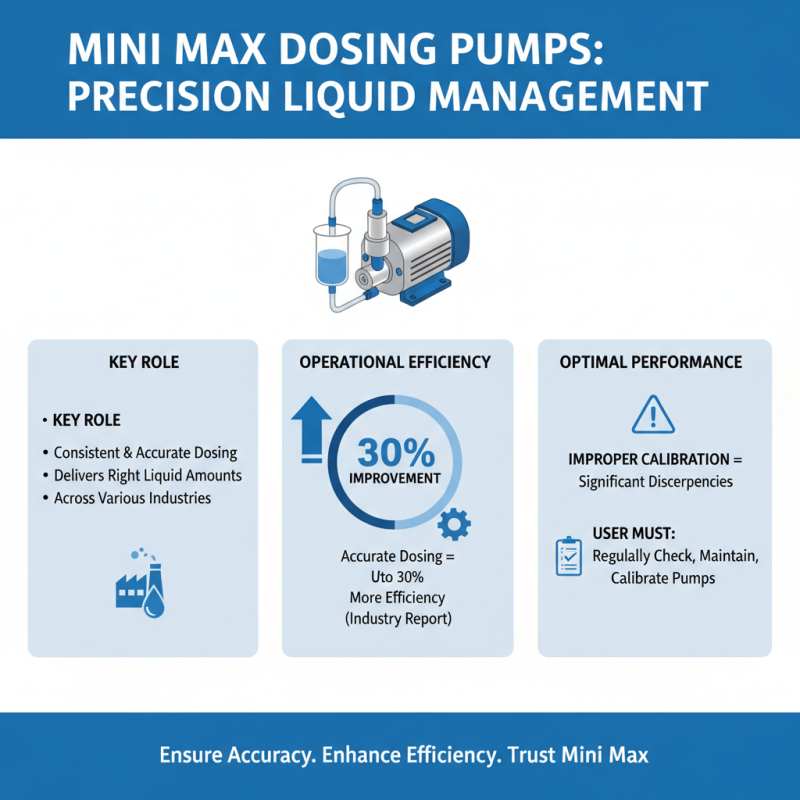

Mini Max dosing pumps play a crucial role in precise liquid management across various industries. These pumps are designed for consistent and accurate dosing, ensuring the right amounts of liquids are delivered every time. According to a recent industry report, accurate dosing can improve operational efficiency by up to 30%. However, improper calibration can lead to significant discrepancies. Users must regularly check and maintain pumps for optimal performance.

The applications of Mini Max dosing pumps are diverse. They are widely used in water treatment, agriculture, and chemical processing. Accurate chemical dosing in water treatment can enhance purification processes. Additionally, in agriculture, precise nutrient delivery supports plant growth. Yet, many establishments overlook regular maintenance checks, which can lead to pump failure. In fact, the same report indicates that nearly 20% of dosing systems fail due to inadequate upkeep.

Attention to detail is essential. Operators must consider factors such as viscosity, temperature, and pressure when using these pumps. An incorrect setup can result in significant cost overruns and safety hazards. Mistakes in liquid management can affect entire production lines. Regular training and knowledge updates for staff are often neglected, impacting overall efficiency.

Mini Max dosing pumps play a vital role in liquid management across various industries. These pumps are designed for precise delivery, ensuring accurate measurements. One key feature is their adjustable flow rates. This allows users to tailor the output to specific needs. Additionally, the pumps often include user-friendly interfaces. This simplifies operation, even for those with limited experience.

Reliability is another essential characteristic. Many models have built-in error detection. This functionality helps prevent mishaps during operation. Even a small fluctuation can lead to significant issues. Regular maintenance is crucial for optimal performance. Users should not overlook the importance of routine checks.

Durability matters too. Mini Max pumps are built to withstand harsh conditions. Some can handle corrosive liquids, adding versatility. However, not all models are perfect for every environment. Careful selection based on application requirements is necessary. A mismatch can lead to inefficiency. Observing these details is essential for achieving effective liquid management.

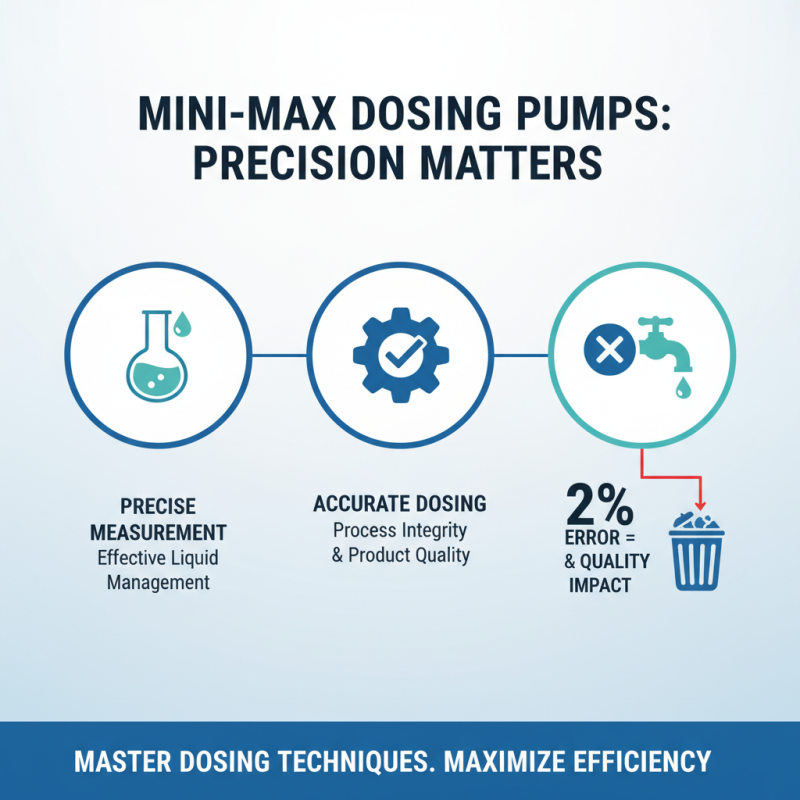

When using mini max dosing pumps, precise measurement is crucial for effective liquid management. Accurate dosing ensures the integrity of processes across various industries. According to industry reports, even a slight error of 2% can lead to significant waste and impact product quality. This underscores the importance of mastering dosing techniques.

One effective tip is to keep the pump and dosing lines clean. Residue buildup can alter flow rates, leading to inaccurate dosages. Regular maintenance checks can significantly improve performance. Additionally, having a calibrated measuring tool can enhance accuracy. Calibration should happen frequently, especially after maintenance or adjustments.

Another consideration is the fluid's viscosity. Different liquids behave differently in the system, affecting their flow rates. If the viscosity changes, pumping may not deliver the expected results. Test your setup with various fluids to identify potential issues. Small adjustments can often lead to improved performance. Each of these steps can boost your dosing accuracy and efficiency.

Accurate liquid management in dosing can be quite challenging. Variability in pump performance often creates issues. Factors such as temperature, viscosity, and chemical composition can impact flow rates. Regular calibration is essential. This helps to maintain consistent dosing precision.

One major challenge is air bubbles in the line. They can disrupt flow and affect accuracy. To overcome this, ensure proper priming of the pump. Using filters can also help reduce the chances of bubbles forming. Check seals and connections regularly to prevent leaks.

Tip: Monitor your system frequently. Small adjustments can lead to significant improvements in accuracy. In some cases, it might be worthwhile to conduct routine checks, even if no issues appear. Keep an eye on wear and tear, as this can impact performance, too. Reflection on these points can help you identify areas of improvement over time.

| Challenge | Solution | Importance | Frequency of Occurrence |

|---|---|---|---|

| Incorrect Calibration | Regular calibration checks every 3 months | High | Monthly |

| Wear and Tear of Components | Scheduled maintenance and replacement every 6 months | Medium | Quarterly |

| Air Bubbles in the System | Implement degassing methods and check pump priming | High | Weekly |

| Inconsistent Flow Rate | Use flow rate monitoring systems | Medium | Daily |

| Chemical Compatibility Issues | Consult material compatibility charts | High | As needed |

Maintaining dosing pumps is crucial for accuracy and longevity. Regular inspections can prevent potential issues. Check for leaks or wear on hoses and fittings. A small leak can disrupt fluid management significantly. Keep an eye on the flow rate; fluctuations can indicate a problem.

Cleaning is just as vital. Residue can accumulate and affect performance. Make it a habit to clean the pump regularly, but don't overdo it. Using harsh chemicals can damage components. Instead, opt for mild solutions that won't harm the pump.

Calibration is another area that needs attention. Periodic calibration ensures precise dosing. However, this process can be tricky. If calibration tools are not accurate, results may be skewed. Training personnel on proper calibration techniques can improve reliability. Reflect on current practices and adjust where necessary. Small changes can enhance overall performance.