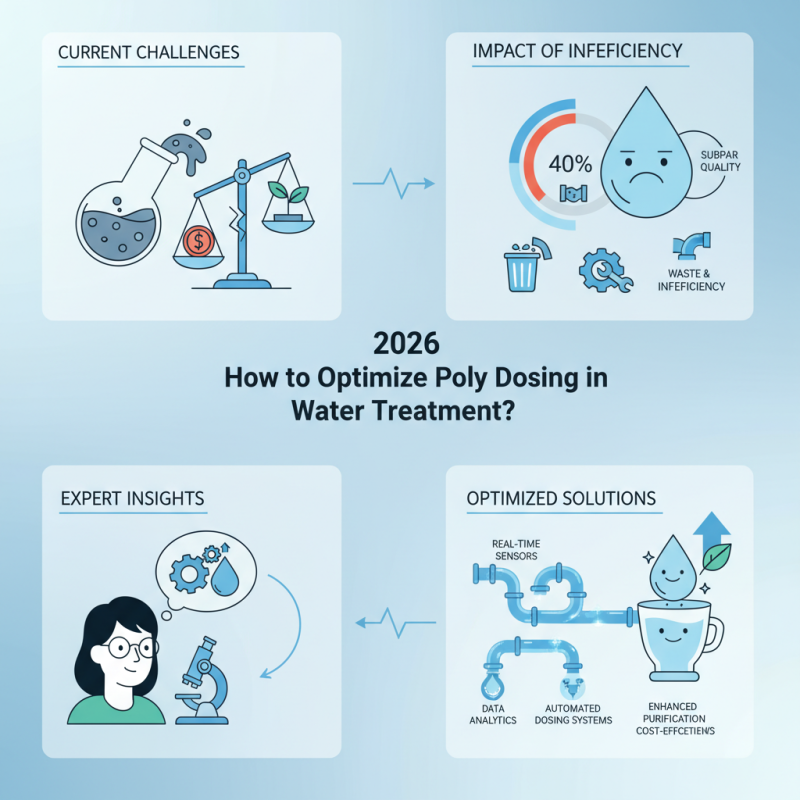

In the realm of water treatment, the importance of optimizing Poly Dosing in Water Treatment cannot be overstated. Recent industry reports suggest that inefficient dosing systems can lead to subpar water quality. According to the Water Quality Association, nearly 40% of treated water does not meet necessary standards due to improper chemicals usage. These statistics highlight the need for careful dosing strategies.

Dr. Emily Carter, a leading expert in water treatment technologies, emphasizes, "Effective poly dosing can significantly enhance water purification outcomes." This statement echoes the industry's shift towards precise chemical application. However, practitioners often struggle with balancing cost and effectiveness in their dosing regimens. Real-world applications show that many facilities still rely on outdated methods, leading to waste and operational inefficiencies.

The challenge lies in identifying the right dosage levels amid varying water qualities. Many facilities have reported discrepancies in chemical performance due to inconsistent dosing practices. This issue prompts reflection on current methodologies and the potential for technological interventions that ultimately improve Poly Dosing in Water Treatment.

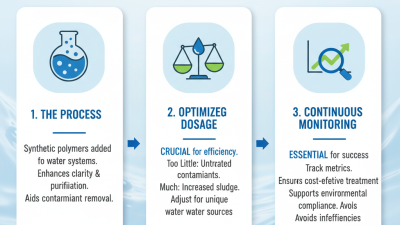

Poly dosing plays a vital role in

water treatment processes. It involves adding

polymers to improve

water clarity and remove unwanted particles. Understanding this process helps operators

optimize their practices. Proper dosing can enhance

flocculation and

sedimentation, leading to

cleaner water.

Tips: Monitor the polymer concentration closely. Too much can lead to

excess sludge. This can complicate the treatment process. Adjust the dosage based on

water quality parameters. Regular testing helps maintain optimal conditions.

Effective mixing is essential for successful poly dosing. Inadequate mixing can result

in uneven distribution of polymers. Operators should ensure thorough agitation in dosing

systems. Fine-tuning the mixing speed might be necessary.

Reflect on past practices;

were they effective? Sometimes, a

fresh approach can yield better results.

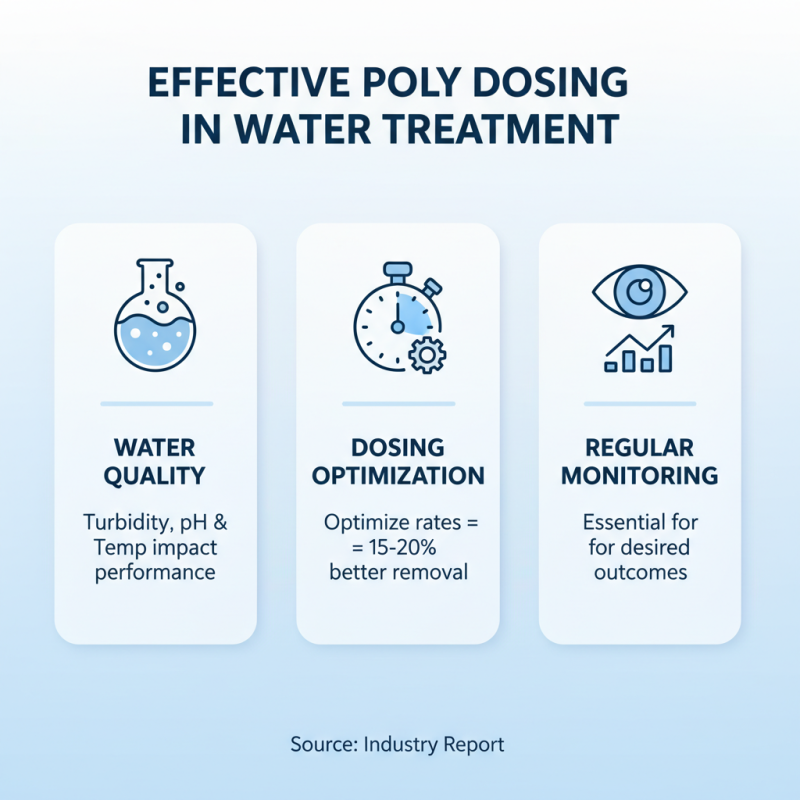

Effective poly dosing in water treatment is influenced by several critical factors. One significant aspect is water quality. Turbidity levels, pH, and temperature can all affect how poly electrolytes perform. For instance, high turbidity levels reduce the efficiency of flocculation. An industry report shows that optimizing dosing rates can improve removal efficiencies by 15-20%. Monitoring these parameters regularly is essential for achieving desired outcomes.

Another factor is the type and concentration of poly used. Different applications and contaminants require specific polymers. For example, cationic polymers are effective for removing organic material, while anionic versions work better for inorganic particles. Adjusting the concentration based on real-time testing is crucial. Many operators still use fixed rates, which can lead to overdosage or underdosage. This practice often results in increased treatment costs and reduced efficacy.

Lastly, the equipment used for dosing plays an important role. Consistent mixing and accurate measurement are vital for optimal performance. If equipment malfunctions, it may lead to inconsistencies in dosing rates. Regular maintenance is required to ensure accurate dosing. Even minor deviations can compromise the overall treatment process. Continuous improvement efforts are necessary to enhance poly dosing strategies.

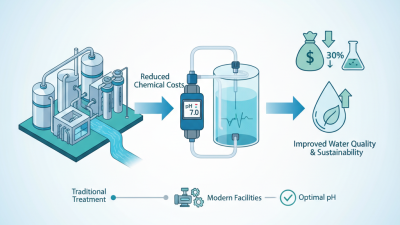

Optimizing poly dosing in water treatment is critical for enhancing water quality. Effective dosing can significantly impact coagulation and flocculation processes. The right dosage improves particle removal. It also minimizes residual chemicals in treated water.

To optimize poly dosing performance, accurate measurements are essential. Operators must regularly calibrate dosing equipment. Monitoring water quality parameters can help determine the required dosage. Environmental factors, such as temperature and pH, play significant roles. These can affect polymer performance. Adjusting for these variables ensures better treatment outcomes.

Implementing a feedback loop is another valuable method. This involves continuously assessing treated water results. If floc size is inconsistent, adjustments are necessary. Operators should be willing to test different dosages. This trial-and-error approach may lead to more effective practices. Reflecting on past performances can guide future dosing strategies. Ultimately, achieving optimal poly dosing can be a complex journey, often requiring time and patience.

The efficiency of poly dosing in water treatment is heavily influenced by water quality. Different water sources pose distinct challenges. For instance, high turbidity levels can hinder the coagulation process. This means operators may need to adjust dosages accordingly to achieve optimal results. Water with varying pH levels can also impact the performance of poly electrolytes. A higher pH may reduce the effectiveness of certain polymers, resulting in more waste and cost.

Another critical factor is the presence of organic matter. Increased organic content usually requires higher dosages of coagulants. Operators often struggle to find the right balance. Too much dosing can lead to undesirable by-products, while too little may not clear the water effectively. Monitoring these factors is essential but can be challenging.

Regular testing and adjustments are vital to maintain efficiency. Operators might miss subtle changes in water quality, leading to inaccuracies in dosing. Reflecting on past experiences can guide better decision-making in the future. In treating water effectively, the focus should always be on constant learning and adaptation. Each batch of water is unique. Proper dosing is not just a science; it's an art that requires careful observation and responsive strategies.

The optimization of poly dosing in water treatment systems is crucial for effective purification. Monitoring in real time allows operators to adjust doses based on actual water quality. Sensors can detect turbidity, chemical concentrations, and pH levels continuously. Such data empowers facilities to respond instantly and avoid chemical overdosing or underdosing.

Using a feedback loop enhances system efficiency. When water quality fluctuates, automatic adjustments can be made. However, manual checks are still necessary. It’s easy to over-rely on technology. Balancing automation with human oversight can prevent errors. Operators should regularly assess sensor accuracy and performance.

Creating a responsive system improves overall treatment efficacy. Yet, challenges remain. Unexpected changes in water composition can confuse automated systems. Operators must adapt and learn from these issues. Continuous training is essential. Emphasizing both technology and human judgment fosters better outcomes in poly dosing strategies.