Effective water treatment is crucial for environmental sustainability and public health. One key factor in this process is **Polymer Dosing Control**. Studies indicate that improper dosing can lead to ineffective treatment and increased operational costs. According to the Water Environment Federation, the right polymer dosage can improve solid removal by up to 30%.

Despite its importance, many facilities struggle with optimizing their dosing systems. Variability in water quality can complicate control strategies. If operators do not calibrate appropriately, they risk over or under-dosing. This not only affects treatment efficacy but can also result in wastage of resources. Reports from industry leaders suggest that even minor dosage miscalculations can lead to significant long-term consequences.

The potential for innovation in polymer dosing control is vast. Implementing advanced monitoring technologies can help in adjusting the dosages dynamically. However, many companies still rely on outdated systems, which may hinder performance. By focusing on effective polymer dosing control, water treatment plants can enhance efficiency, reduce costs, and improve compliance with environmental regulations.

Polymers play a critical role in water treatment processes. They aid in coagulation and flocculation, essential for removing turbidity and contaminants. According to the Water Environment Federation, effective polymer dosing can enhance the removal of suspended solids by up to 90%. However, improper dosing can lead to suboptimal results or excessive sludge production.

Different types of polymers exist, each with unique properties. Anionic and cationic polymers interact differently with particles in water. For example, cationic polymers are often more effective in treating waters with high negative charge. Yet, choosing the wrong type can harm the process. Many facilities report that over 20% of polymer doses are wasted. This inefficiency raises operational costs and impacts the environment.

Optimizing the dosing process is essential. Monitoring parameters like pH and temperature can improve performance. Data shows that small adjustments in dosing concentration can lead to substantial improvements. Facilities must invest in real-time monitoring systems. The need for constant adjustment highlights a gap in many existing processes. Balancing efficiency and cost is vital for sustainable water treatment.

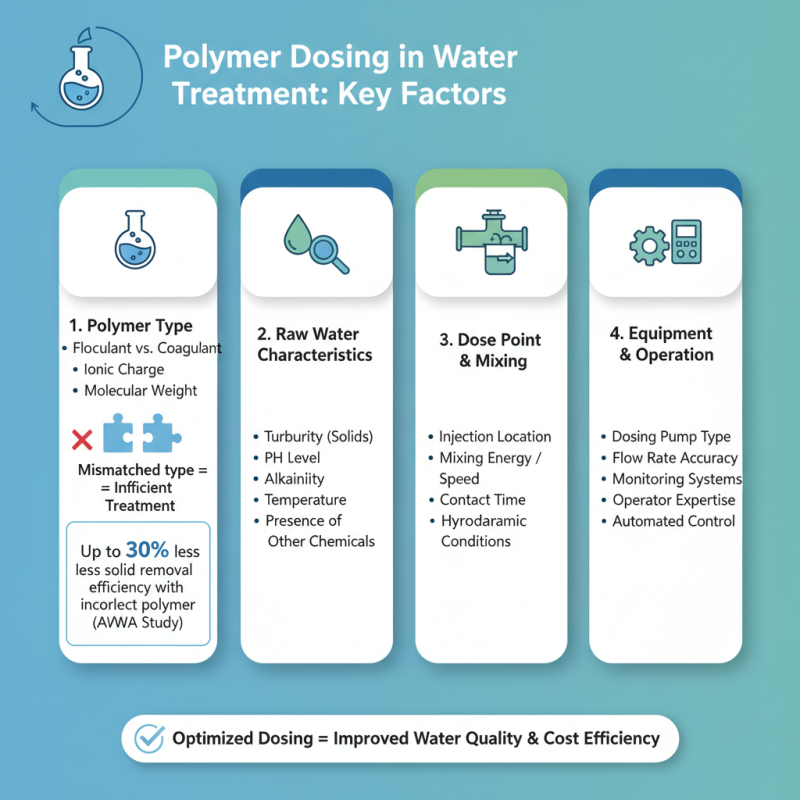

Polymer dosing in water treatment is influenced by several critical factors. The type of polymer used plays a significant role. Different polymers serve unique purposes, such as flocculation or sedimentation. According to industry reports, a mismatch can lead to inefficient treatment. A study from the American Water Works Association indicates that incorrect polymer use can reduce solid removal efficiency by up to 30%.

Another important factor is the water quality. Variations in turbidity, pH, and temperature affect polymer performance. For instance, elevated turbidity levels often require higher doses. A report by the Water Environment Federation highlights that dosages must be adjusted for different water sources. Failing to account for these variables can result in over-dosing or under-dosing, both of which are problematic. Many facilities struggle with achieving optimal dosing due to fluctuating water characteristics.

Finally, operator training is often overlooked. Even with precise data, improper application can occur. A survey revealed that nearly 40% of operators feel they lack adequate training in polymer dosing. This gap can lead to inconsistent results. Ongoing education is essential, as it enhances understanding and improves dosing accuracy. Balancing these factors is vital for effective water treatment. Inadequate attention to these elements often leads to operational inefficiencies.

Effective water treatment relies heavily on polymer dosing control. Monitoring polymer dosing efficiency is crucial to achieving optimal results. One technique is to regularly measure the turbidity of treated water. If turbidity levels rise, it could indicate inadequate polymer dosing. This quick assessment can help adjust dosing in real time.

Another method focuses on using flow rates to optimize dosing. Adjusting the flow rate of incoming water can impact how polymers perform. For example, low flow rates may require more concentrated doses. Yet, this approach might not always work; sometimes, too much polymer can lead to waste or ineffective treatment. Balancing these variables demands careful attention and frequent adjustments.

Visualization tools can enhance monitoring efforts. Implementing data dashboards can track trends in dosing efficiency. However, data overload can lead to confusion. It's important to filter out noise and focus on significant changes. Relying solely on tech might overlook human insights. Active operator involvement remains essential in this optimization process.

Optimizing polymer dosing control in water treatment is crucial. It can significantly enhance efficiency and reduce costs. Treatment plants often struggle with inconsistencies in polymer application. Monitoring the performance of dosing systems can help identify issues. Regular calibration and maintenance are essential. Small changes can lead to big improvements, but many plants overlook this.

One best practice is to implement automation. Automated systems can adjust polymer doses based on real-time data. This ensures that the right amount is applied, reducing waste. However, reliance on technology may cause operators to overlook manual checks. A balance between automation and human oversight is vital. Operators should regularly review performance data and make adjustments as needed.

Another key aspect is staff training. Well-trained personnel can detect problems early. They should understand how polymers behave in different conditions. Regular workshops and updates can keep staff informed. Many plants neglect this aspect, leading to inefficiencies. Investing in training helps create a knowledgeable workforce. Ultimately, a focus on both technology and human skills will enhance polymer dosing in treatment processes.

Effective water treatment relies heavily on precise polymer dosing. Proper dosing can improve water clarity and reduce contaminants. Studies indicate that overdosing can lead to poor flocculation and increased chemical costs. For instance, an industry report highlights that optimizing polymer use can reduce costs by 20%.

Polymers enhance sedimentation in water treatment, but too much can slow the process. A facility that saved on cost by 15% improved its overall efficiency. It's crucial to find the right balance in dosage to ensure water quality. Regular monitoring and adjustments are necessary. This can avoid wasting resources and improve treatment outcomes.

**Tip:** Regularly assess water quality parameters. This helps fine-tune the dosage. **Tip:** Implement feedback loops for continuous improvement. Small adjustments can lead to significant cost savings. Be open to refining your approach based on real-time data. Avoiding guesswork encourages better decision-making.

| Parameter | Optimal Value | Impact on Water Quality | Treatment Cost ($/m³) |

|---|---|---|---|

| Polymer Type | Anionic | Enhances flocculation | 0.15 |

| Dosage Rate (ppm) | 5-10 | Optimal coagulation | 0.12 |

| pH Level | 6.5 - 8.5 | Maximize efficiency | 0.10 |

| Retention Time (min) | 30 | Improves settling | 0.08 |