In the quest for enhanced process efficiency, optimizing Polymer Dosing Control is crucial for a variety of industries, including water treatment, pharmaceuticals, and food production. Polymer dosing serves as a vital component in processes that require flocculation, coagulation, and stabilization, significantly impacting both operation costs and product quality. However, achieving the right balance in polymer dosages can be challenging, as it often involves intricate variables such as flow rates, concentration levels, and the characteristics of the materials involved.

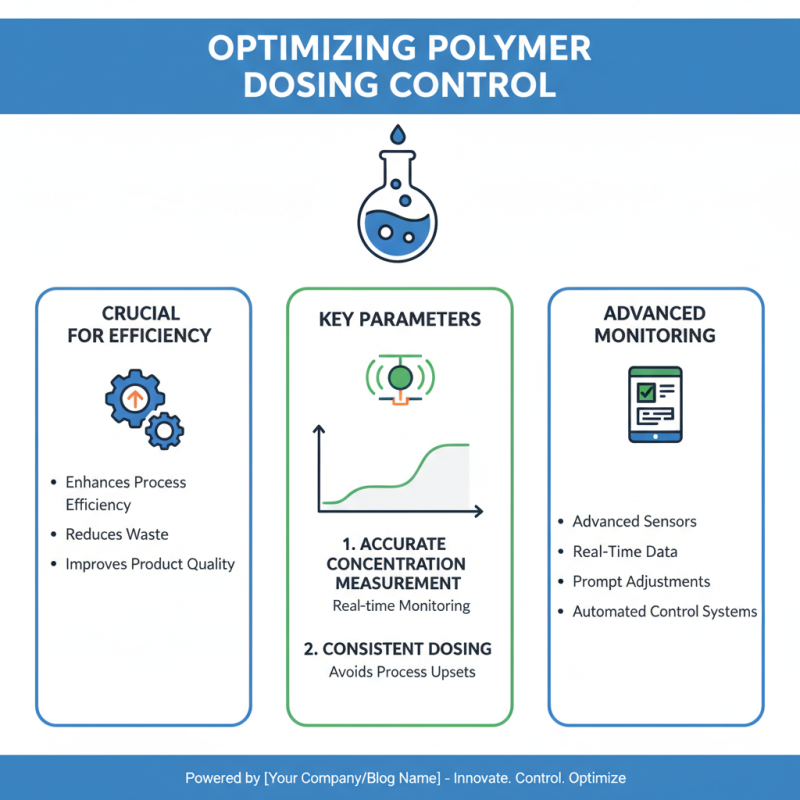

Effective Polymer Dosing Control not only maximizes the performance of polymers but also minimizes waste and operational inefficiencies. By implementing advanced monitoring techniques and automation, facilities can ensure precise dosing that aligns with real-time needs. This precision helps to address fluctuating conditions within a process, allowing for adaptive strategies that respond to changes promptly. Ultimately, a well-optimized dosing strategy can lead to reduced chemical consumption, lower environmental impact, and improved overall output.

In this article, we will explore key strategies for optimizing Polymer Dosing Control, including the integration of data analytics, feedback loops, and system automation. By focusing on these elements, organizations can unlock the full potential of their polymer applications, leading to not only cost savings but also enhanced sustainability in their operations.

The role of polymer dosing in industrial processes is crucial for enhancing product quality and process efficiency. Polymers are commonly used in various applications, such as water treatment, paper manufacturing, and mining, where they facilitate separation and stabilization of different materials. For instance, a study by the American Chemical Society reported that optimizing polymer dosing can lead to a 25% reduction in chemical costs, significantly impacting the overall operational expenses.

One of the most effective strategies for optimizing polymer dosing is through precise control mechanisms that adjust the dosage according to real-time process conditions. Employing advanced monitoring techniques, such as turbidity sensors, can help in determining the optimal polymer quantity needed for effective flocculation. This dynamic approach not only minimizes waste but also ensures that the desired treatment outcomes are consistently achieved.

Tips: Regularly calibrate dosage equipment to maintain accuracy and integrate automation technologies to enable responsive adjustments based on fluctuating process conditions. Conduct periodic assessments of polymer performance to identify any changes needed in dosing strategies, ensuring maximum efficiency. Incorporating these practices can lead to substantial improvements in both productivity and cost savings in industrial operations.

Effective polymer dosing control is crucial for enhancing process efficiency in various industrial applications. Several key parameters influence the efficiency of polymer dosing control. One of the primary factors is the accurate measurement of polymer concentration within the solution. Variations in concentration can lead to inconsistent dosing, which may adversely affect the overall process. Monitoring systems equipped with advanced sensors can provide real-time data, enabling operators to adjust dosing rates promptly based on current conditions.

Another significant parameter is the flow rate of the process stream to which the polymer is being added. Maintaining a consistent flow rate is vital for achieving optimal mixing and achieving the desired treatment outcomes. It is essential to calibrate dosing equipment to ensure that the polymer is injected at the correct rate in relation to the flow of the process. Additionally, the temperature and pH of the solution can also affect polymer performance, as certain polymers may behave differently under varying conditions. Therefore, continuous monitoring and adjustment of these parameters are necessary to maximize the effectiveness of polymer dosing and, consequently, the overall process efficiency.

Effective polymer dosing control is crucial for enhancing process efficiency in various industries, including water treatment and chemical manufacturing. Accurate measurement and monitoring of polymer dosing not only ensure optimal performance but also reduce costs associated with overuse or underuse. According to a report by the American Institute of Chemical Engineers, optimizing polymer dosing can improve overall process efficiency by 15-30%, highlighting the need for precise control systems.

To achieve accurate measurement, implementing advanced monitoring technologies, such as flow meters and automated dosing systems, is essential. These tools can provide real-time data on polymer concentrations and flow rates, enabling operators to make informed adjustments. Utilizing data analytics can further enhance decision-making, as trends and anomalies in polymer usage can be identified, allowing for proactive management.

Tips: Regular calibration of dosing equipment is vital to maintain accuracy. Consider conducting routine maintenance checks to ensure that all components are functioning correctly. Additionally, training personnel on best practices for monitoring and adjusting polymer doses can lead to a more efficient process, reducing waste and improving overall performance.

Optimizing polymer dosing control can significantly contribute to cost reduction and enhance resource efficiency in various industrial processes. By fine-tuning the amount of polymer used during operations, companies can minimize waste and eliminate excess consumption. This precision not only lowers material costs but also reduces the frequency of polymer replacement, leading to a greater return on investment. Accurate dosing ensures that only the necessary quantity of polymer is utilized, thus preventing overspending on materials that do not improve process outcomes.

Moreover, efficient polymer dosing can lead to improved operational performance by enhancing the stability and effectiveness of the treatment processes. When polymer dosing is optimized, it can result in better particle aggregation and flocculation, improving separation processes and minimizing energy consumption. This efficiency translates into lower operational costs, as processes can run smoother and require less energy input. Ultimately, implementing advanced polymer dosing strategies can create a more sustainable operation by reducing the environmental footprint associated with excess material usage and energy expenditure.

Enhanced polymer dosing systems have demonstrated significant improvements in process efficiency across various industries. In one case study, a wastewater treatment facility faced challenges with inconsistent polymer dosing, leading to suboptimal flocculation and increased operating costs. By implementing a smart dosing control system that utilized real-time monitoring and adjustment capabilities, the facility was able to optimize polymer usage. As a result, not only did the flocculation process improve, but the facility also noted a 20% reduction in polymer consumption and lower overall maintenance requirements.

Another successful implementation was observed in a chemical manufacturing plant, where the integration of advanced sensors and automated feedback loops transformed the dosing process. The system continuously analyzed parameters such as flow rates and polymer viscosity, ensuring accurate dosing at all times. The outcome was remarkable: production rates improved, and the quality of the final product met the stringent regulatory standards more consistently. This streamlined approach not only enhanced operational efficiency but also contributed to a significant decrease in waste, showcasing the benefits of modernized polymer dosing systems in industrial applications.