In the evolving landscape of water treatment technology, the importance of maintaining optimal pH levels cannot be overstated. A pH dosing pump is integral to this process, as it precisely regulates the acidity or alkalinity of water, thereby enhancing treatment efficacy. According to industry reports from the Water Environment Federation, maintaining appropriate pH levels can improve chemical efficacy by up to 30%, which in turn can lead to significant cost savings in chemical usage and reduced environmental impacts.

Experts agree that adopting advanced solutions like a pH dosing pump is essential for modern water treatment facilities. Dr. Jane Smith, a leading authority in water quality management, emphasizes, "Incorporating a pH dosing pump into your treatment process not only streamlines operations but also ensures compliance with increasingly stringent water quality regulations." As water treatment demands evolve, leveraging the capabilities of pH dosing pumps can no longer be seen as optional but as a necessary step towards sustainable and efficient water management practices.

By analyzing data from recent studies, it is clear that facilities utilizing pH dosing pumps report lower chemical costs and improved water quality outcomes. As such, investing in a pH dosing pump should be a strategic decision for any facility looking to enhance its water treatment processes and sustainability efforts.

pH control is a fundamental component in the water treatment process, playing a critical role in ensuring water quality and compliance with environmental regulations. Maintaining optimal pH levels is essential for several reasons, including the prevention of corrosion, scaling, and the effective functioning of disinfection processes. According to the American Water Works Association, improper pH levels can lead to extensive damage to water treatment infrastructure, with repair costs often running into millions of dollars annually.

Moreover, the significance of pH control extends to public health and safety. A study published by the World Health Organization indicates that water with an unsuitable pH level can hinder the effectiveness of disinfection agents, thus allowing harmful microorganisms to thrive. This not only poses health risks but can also violate strict water quality standards set forth by regulatory bodies. Implementing effective pH dosing systems ensures that treatment facilities can maintain water quality while minimizing operational risks, contributing to safer drinking water for communities.

In addition, the economic benefits of a well-managed pH control system cannot be overlooked. According to a report by the Water Environment Federation, effective pH adjustment methods can reduce chemical usage by up to 30%, leading to significant cost savings. These cost-effective measures, combined with improved water quality and operational efficiency, make a compelling case for investing in advanced pH dosing pumps that are critical for any modern water treatment facility.

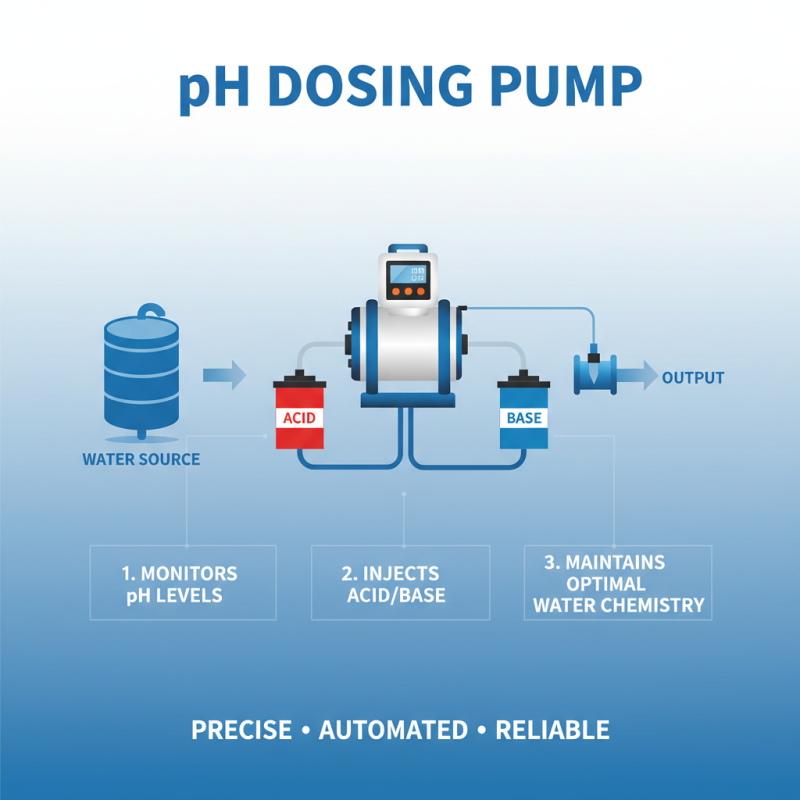

A pH dosing pump is a sophisticated piece of equipment designed to maintain the ideal pH levels in water treatment systems. These pumps operate by accurately injecting an acid or base solution into water sources to adjust acidity or alkalinity, ensuring optimal conditions for various applications, such as swimming pools, industrial processes, and wastewater treatment. The pumping mechanism typically relies on a diaphragm, which allows for precise control over the flow rate and volume of the dosing solution, providing users with reliable and automated management of their water chemistry.

The working principle of a pH dosing pump involves a feedback loop that continuously monitors the water’s pH levels. This real-time monitoring is often achieved through the integration of pH sensors that relay data to a control unit. When the pH level deviates from the setpoint, the control unit activates the pump to introduce the necessary chemicals to correct the imbalance. This automated system not only enhances the accuracy of pH control but also allows for consistent water quality, reducing the need for manual adjustments and enhancing the overall efficiency of water treatment processes.

A pH dosing pump is an essential tool for maintaining optimal water quality in various treatment processes. One of the primary benefits of using a pH dosing pump is its ability to deliver precise chemical dosage. This ensures consistent pH levels, which is vital for preventing system corrosion and enhancing the effectiveness of disinfection methods. By accurately controlling pH, you can optimize conditions for chemical reactions and biological processes, leading to improved overall water treatment efficiency.

Tips for selecting the right pH dosing pump include considering the flow rate and pressure requirements of your system. Ensure that the pump is compatible with the chemicals you intend to use and that it offers reliable, consistent performance. Regular maintenance is also crucial; keeping the pump clean and regularly checking for wear can help avoid costly downtime.

Another significant advantage of pH dosing pumps is their automation capability. Many pumps can be integrated with water quality monitoring systems, allowing for real-time adjustments. This automation not only reduces the manpower needed but also minimizes errors associated with manual dosing. Ensuring that operators receive training on how to interpret readings and manage the system can further enhance the performance and longevity of the equipment.

When selecting a pH dosing pump for your water treatment needs, several critical factors come into play that can significantly impact the efficiency and effectiveness of the system. First, it’s essential to consider the flow rate requirements of your application. Depending on the volume of water being treated and the desired pH levels, the flow rate will determine how quickly chemicals can be introduced into the water. Ensuring that the pump can meet these demands is vital for maintaining optimal pH levels consistently.

Another important aspect is the type of chemicals you plan to use with the pump. Different chemicals have varying viscosities and corrosive properties, which can affect the performance of the pump. Choosing a pump with materials that are compatible with the chemicals helps prevent corrosion and ensures longevity. Additionally, consider the pump's accuracy and control features. A good dosing pump should provide precise adjustments to pH levels and allow for easy programming to accommodate fluctuating conditions in water chemistry. Overall, evaluating these factors thoroughly will guide you in choosing the right pH dosing pump to enhance your water treatment processes effectively.

Maintaining a pH dosing pump is crucial for ensuring its optimal performance in water treatment processes. Regular inspections should be scheduled to assess the pump's mechanical components, such as seals and valves, for any signs of wear or leaks. It's essential to keep the dosing lines clean and free from blockages to allow for a consistent and accurate flow rate. Operators should also familiarize themselves with the pump's calibration settings, as this helps maintain the correct dosing levels and achieves the desired pH balance in the water.

Implementing best practices for pH dosing pumps can significantly extend their lifespan and enhance their reliability. Operators should establish a maintenance routine that includes frequent cleaning, inspection, and recalibration of the pump. Additionally, using appropriate safety precautions and protective gear is recommended when handling chemicals involved in pH adjustment, as these can pose health risks. Training for personnel on proper usage and troubleshooting can aid in swiftly addressing any issues and minimizing downtime, ensuring that water treatment continues smoothly and effectively.