Polymer Dosing Control is a critical aspect of wastewater treatment and various industrial applications. According to a recent market analysis by Research and Markets, the global polymer dosing control system market is expected to reach $2.8 billion by 2025, growing at a CAGR of 6.5%. This growth highlights the increasing demand for efficient water treatment solutions.

Experts like Dr. Emily Carter, a leading researcher in polymer technology, state, “Optimal polymer dosing is vital for process efficiency and cost-effectiveness.” Her insights reflect the complexity and precision involved in polymer dosing control. It requires a deep understanding of chemical interactions and systematic monitoring to achieve desired results.

However, the road to achieving perfect dosing is fraught with challenges. Industry reports indicate that many facilities struggle with calibration and maintenance of dosing systems. This inconsistency can lead to over or under-dosing, resulting in increased costs and inefficient treatment processes. As the sector evolves, addressing these shortcomings will be essential for maximizing the benefits of Polymer Dosing Control.

Polymer dosing control systems play a critical role in various industrial processes. These systems regulate the amount of polymer added to sludge treatment or water purification systems. Proper control of polymer dosing can enhance efficiency and reduce waste. A well-calibrated system ensures optimal treatment without unnecessary chemical usage.

According to recent data, a failure in dosing control can lead to a 15% increase in operational costs. Overdosing or underdosing not only impacts treatment efficiency but also affects the environment. Studies indicate that plants using advanced dosing control technologies reported a 20% reduction in chemical consumption. However, the implementation of these systems can be complex and may require specialized training.

An effective polymer dosing control system includes flow meters and controllers that adjust the dosage automatically. Inconsistent dosing can lead to subpar treatment results. Operators must regularly revisit the system settings and ensure routine maintenance. Industry professionals emphasize the need for constant evaluation to adapt to fluctuating conditions in treatment processes. The quest for perfect polymer dosing remains an ongoing challenge for many facilities.

Polymers play a significant role in water treatment. They help separate solids from liquids effectively. These long molecules can change the properties of water, making it easier to purify. Adding polymers enhances the coagulation and flocculation processes. This leads to clearer and cleaner water.

In practical terms, dosing control of polymers is crucial. Too much polymer can create issues. It may cause excess sludge or reduced performance. Conversely, too little can lead to incomplete treatment. Finding the right balance is key to effective water management. Operators must monitor dosage closely for optimal results.

Tips: Regularly check polymer concentrations for accuracy. Adjust doses based on water quality. Observe treatment performance regularly to make necessary changes. Remember, even slight miscalculations can impact the entire process.

| Parameter | Description | Typical Range | Impact on Water Treatment |

|---|---|---|---|

| Polymer Type | Variety of polymers used for flocculation | Anionic, Cationic, Nonionic | Affects floc size and settling rates |

| Dosing Rate | Amount of polymer per unit volume of water | 1-5 mg/L | Direct correlation with treatment efficiency |

| pH Level | Acidity or basicity of water | 6.5 - 8.5 | Influences polymer performance and charge |

| Mixing Intensity | Power and type of mixing applied | 100-500 RPM | Affects polymer dispersion and effectiveness |

| Contact Time | Duration polymers are in contact with water | 30 seconds to 5 minutes | Important for floc formation |

Polymer dosing control plays a vital role in various industries. It involves adding precise amounts of polymer to a process. This ensures optimal performance and efficiency. Understanding the mechanisms behind polymer dosing can enhance outcomes.

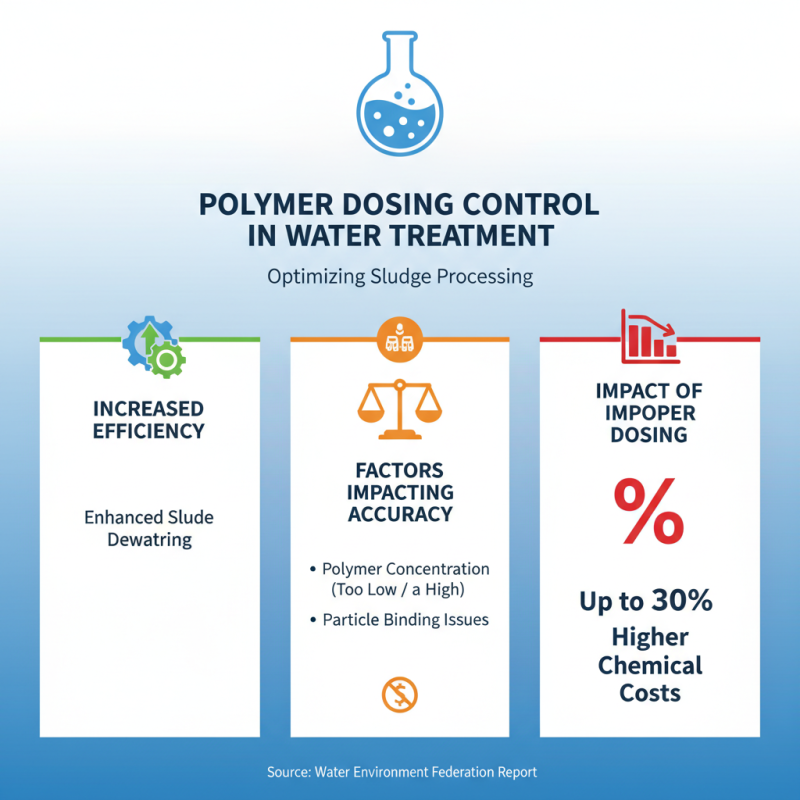

Polymer dosing control plays a critical role in water treatment processes. It enhances the efficiency of sludge processing, yet several factors impact its accuracy. One significant factor is the polymer concentration. A concentration that is too low fails to effectively bind with particles. Conversely, an excess concentration can lead to floc formation issues, causing operational inefficiencies. A report from the Water Environment Federation indicates that improper dosing can increase chemical costs by up to 30%.

The method of mixing also influences dosing efficiency. Poor mixing can create uneven distribution of the polymer, undermining its overall effectiveness. Studies show that optimal mixing can improve flocculation rates by as much as 25%. Furthermore, temperature variations in the application environment can affect polymer behavior. Cold temperatures often slow reactions, while high temperatures can accelerate them unpredictably. Accurate temperature control can enhance polymer activation and improve treatment outcomes.

Another factor is the feed rate control. Inconsistent feed rates impact dosage precision. A lack of calibration can lead to significant deviations in actual dosing amounts. It has been documented that fluctuations in feed rates can increase sludge retention time by 15%. Monitoring these parameters is essential for achieving reliable dosing accuracy. Operators must regularly assess their dosing systems to identify inefficiencies.

Implementing polymer dosing control presents various benefits and challenges. On the positive side, effective dosing can enhance water treatment processes. According to a report from the Water Environment Federation, proper polymer application can improve sludge dewatering efficiency by up to 30%. This can lead to substantial cost savings on disposal and energy use.

However, challenges exist. Precise dosing requires continuous monitoring, which increases operational complexity. A study by the American Society of Civil Engineers noted that 20% of facilities struggle with inconsistent dosing rates. This inconsistency can compromise treatment effectiveness and lead to increased solid waste. Additionally, selecting the right polymer type is crucial. Not all polymers are suitable for every application, which can complicate decision-making.

There is also the issue of potential over-dosing. This can introduce more chemicals into the system than necessary. Over-dosing can result in higher operational costs and may affect effluent quality. Facilities must find a balance to optimize performance without compromising safety or compliance. These factors highlight the need for ongoing assessment in polymer dosing strategies.