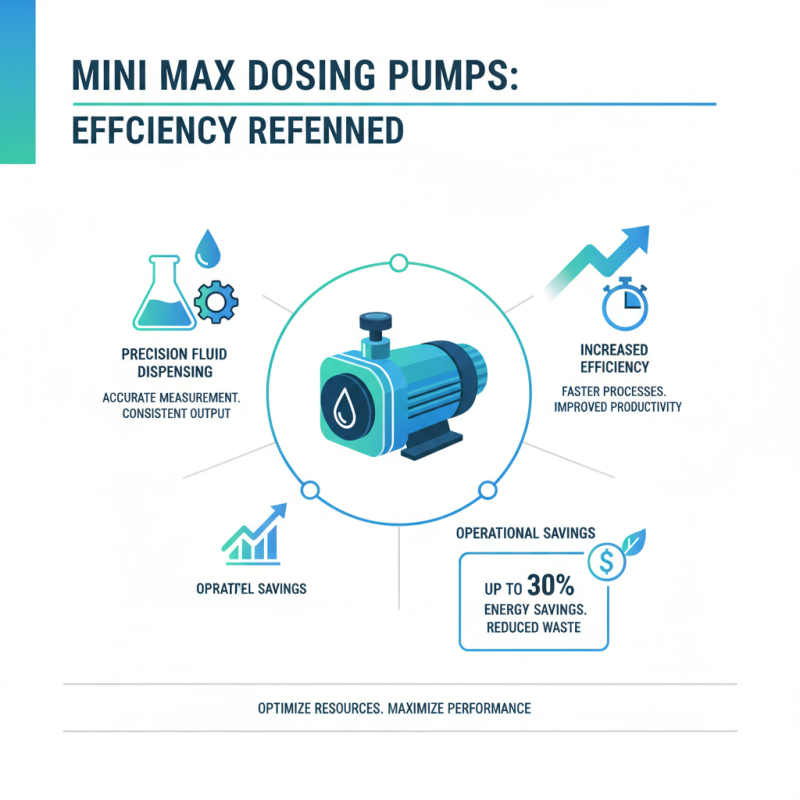

In the fast-evolving field of industrial automation, Mini Max Dosing Pumps have emerged as essential components. According to recent reports, the global dosing pump market is expected to grow significantly, driven by increasing demand across various sectors. These pumps are crucial for accurate fluid dispensing, particularly in chemical processing, pharmaceuticals, and food production.

Mini Max Dosing Pumps not only enhance precision but also improve overall operational efficiency. Their compact size makes them ideal for spaces where traditional pumps fall short. However, choosing the right pump can be challenging. Many businesses overlook key features, leading to inefficiencies and increased costs.

Investing in the right Mini Max Dosing Pump requires careful consideration of specific business needs. While the market offers numerous options, understanding each pump's unique capabilities is vital. Many companies find themselves dissatisfied with their choices, highlighting the need for better guidance and decision-making in this area.

Mini Max dosing pumps play a crucial role in various industries. These pumps are designed for precise chemical dosing. Their ability to deliver consistent performance makes them essential for many business operations. A mini max dosing pump is compact yet powerful, ideal for applications with limited space. This device controls the flow rate and dosage with high accuracy.

The importance of these pumps cannot be overstated. They help maintain product quality in numerous processes. Inconsistent dosing can lead to serious issues. Mistakes can result in costly waste or even safety hazards. It's also interesting to note that, despite their simplicity, some users struggle with setup and calibration. This can lead to frustration and reduced efficiency. As businesses adopt these pumps, they must also invest in training for optimal use. Adopting new technology often requires adjustment, and mini max dosing pumps are no different.

When choosing mini max dosing pumps for your business, it's vital to consider key features. The flow rate is crucial. You need an appropriate rate that suits your application. Different operations require varying flow rates. An adjustable rate allows for better flexibility.

Tip: Assess the maximum output of the pump. Too low, and you may struggle with your processes. Too high, and you risk wastage. Consider your specific needs before making a choice.

Another essential feature is accuracy. Dosing pumps should deliver the exact amount required. Inaccurate dosing can lead to product inconsistencies. You may face challenges in quality control. Look for pumps that offer precision.

Tip: Check if the pump has an adjustable dosing mechanism. This can help fine-tune outputs. It can also reduce errors during operations.

Durability is another aspect not to overlook. Pumps should withstand the demands of your business environment. A reliable pump reduces downtime. It may seem like an investment. However, it pays off in the long run.

Tip: Look for materials that resist corrosion. This is especially important in harsh environments. Keeping maintenance costs low is key, but don’t compromise on quality. Evaluate any potential pitfalls that can affect the lifespan of the pump.

This chart compares the flow rates (in liters per hour) of 10 different mini max dosing pumps, providing a visual representation to help businesses assess which pump may meet their operational needs effectively.

When choosing a mini max dosing pump, performance is key. These pumps cater to various industries, delivering precise measurements. Efficiency often hinges on flow rates and pressure ranges. Some models excel in high-pressure environments, while others perform better in lower ranges. It's important to analyze these factors based on your specific requirements.

Consider the user interface as well. Simplicity enhances operation during daily tasks. A pump with a complicated setup can lead to mistakes. Ease of calibration also matters; if it's tough, it may hinder accuracy. Look for features like automatic recalibration. This can save time and effort, but not all pumps offer it.

Tip: Always check reviews before buying. Real-world feedback reveals potential issues. Don't solely rely on specifications; user experiences often tell the real story. Test the pump if possible. Understanding its limitations is crucial. A pump that appears perfect may have flaws hidden behind flashy features. Stick to what suits your unique business needs. Explore each option thoroughly.

Dosing pumps play a vital role in various industrial applications. In manufacturing, they ensure precise chemical mixing, critical for product consistency. These pumps are essential in processes like wastewater treatment and food production. They regulate the flow rate to maintain quality standards. Each application requires specific dosing capabilities. This makes selecting the right pump essential.

In chemical processing, dosing pumps facilitate the safe handling of hazardous materials. They minimize the risk of spills and exposure. Accurate dosing is crucial for reactions. This enhances efficiency and safety. However, operators must regularly check pump calibration. An error can lead to significant production issues. Training staff on proper usage is often overlooked. It's an area deserving attention.

Some industries might shy away from investing heavily in dosing technology. They fear a steep learning curve or high maintenance. Yet, the benefits outweigh these concerns. When done correctly, dosing processes can greatly enhance productivity. Resolving these doubts is key for growth in manufacturing and chemical applications.

Mini Max dosing pumps are becoming essential for various industries. They provide precise fluid dispensing. This precision leads to increased efficiency. Reports show that energy-efficient systems can cut operational costs by up to 30%. Mini Max pumps are designed with this in mind. They help optimize resources while minimizing waste.

Cost-effectiveness is a major selling point. Many businesses face tight budgets and increasing energy prices. An efficient dosing pump can alleviate these pressures. According to industry data, investing in quality pumps often yields a return on investment within a year. However, initial costs might deter some companies. Selecting the right pump requires careful consideration of specific needs.

Energy savings can also vary greatly. Certain models may not perform as expected under specific conditions. Understanding flow rates and chemical compatibility is crucial. If not addressed, these factors can lead to increased maintenance costs. It's essential for businesses to reflect on their choices. Investing in poorly matched equipment may hinder long-term savings.