In various industries, the choice of a dosing pump is crucial. Among the options available, a Membrane Dosing Pump stands out for multiple reasons. It offers precise control and ensures accurate chemical dosing. This pump type is designed for compatibility with different fluids, making it versatile for various applications.

Membrane Dosing Pumps can be used in water treatment, agriculture, and chemical processing. They effectively manage the injection of chemicals into tanks or pipelines. Their reliability is key in environments that require consistency. However, these pumps are not without limitations. Understanding their maintenance needs is essential for optimal performance.

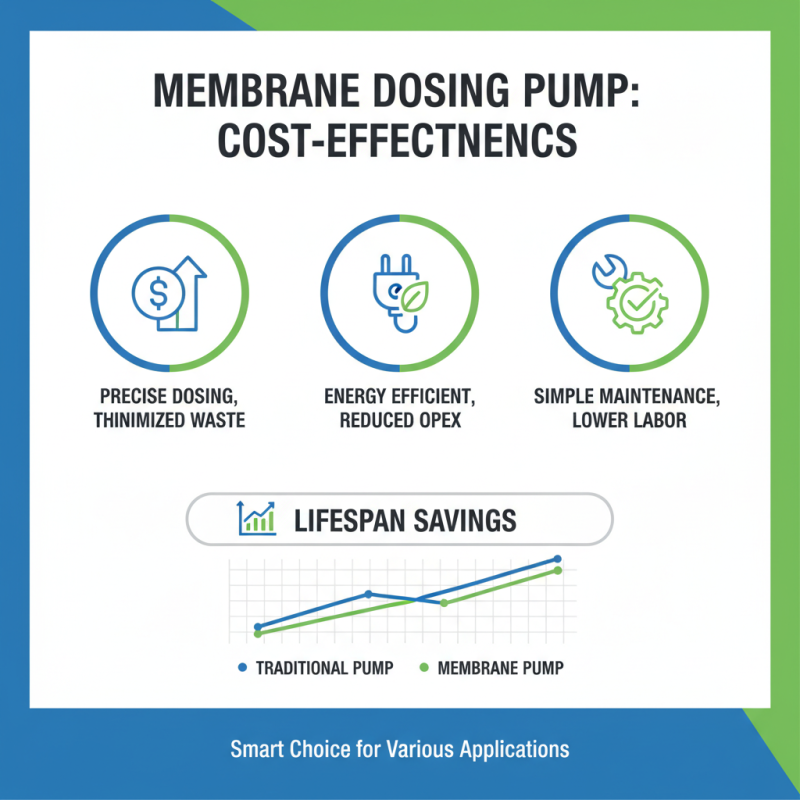

Budget considerations often arise. Some may find Membrane Dosing Pumps costlier than other options. Yet, the benefits can justify the investment. Evaluating operational costs over time is necessary. The right choice can lead to efficient processes and long-term savings.

Membrane dosing pumps have become popular in various chemical applications. They offer precise control over the flow of fluids. This accuracy is crucial in scenarios where dosage consistency is essential. These pumps can handle a wide range of chemicals, including corrosive substances. The ability to use them in harsh conditions is an added advantage.

One of the key benefits is their durability. Membrane pumps generally require less maintenance compared to other types. This factor directly impacts operational costs. However, it's important to note that they can be sensitive to temperature changes. Regular checks are necessary to ensure optimal performance.

Tips: Always calibrate your pump before use. This step is vital for achieving desired results. Monitor the system regularly to catch any inconsistencies early. Opt for models that provide feedback on performance metrics. In cases of failure, replacing the membrane can often restore the pump's functionality.

When selecting a dosing pump, precision is often a top priority. Membrane dosing pumps excel in delivering consistent and accurate volumes. According to a recent industry report, these systems achieve a repeatability rate of over 98%. This level of accuracy helps reduce waste and ensures compliance with stringent industry standards.

Many industries rely on precise dosing for various applications. For instance, in chemical processing, any deviation can lead to subpar product quality. A slight inconsistency can compromise safety and efficiency. Membrane pumps address this issue effectively, featuring adjustable stroke lengths and variable speeds, which enhance control over the dosing process.

However, challenges remain. Regular maintenance is crucial to sustaining performance. Blockages and wear can disrupt the pump’s operation. Operators need to be vigilant. Furthermore, while membrane dosing pumps are known for high precision, external factors—like temperature fluctuations—can still affect accuracy. Adapting to these variations is key for optimal performance in real-world applications.

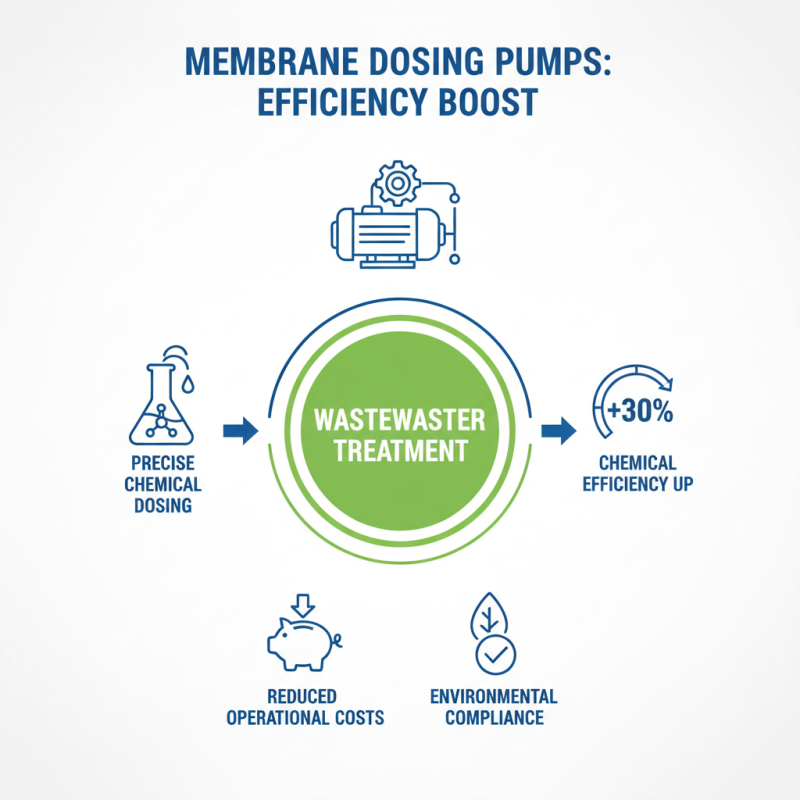

Membrane dosing pumps are increasingly popular due to their industry-specific efficiency. In the wastewater treatment sector, for example, these pumps deliver precise chemical dosing. A recent study revealed that using membrane dosing pumps can enhance chemical efficiency by up to 30%. This significant improvement helps reduce operational costs while maintaining compliance with environmental regulations.

In the food and beverage industry, membrane dosing pumps ensure accurate liquid ingredient management. They prevent over dosing, which can spoil products. Performance data shows a reduction in waste by 25% when these pumps are employed. However, even with advancements, maintenance can present challenges. Regular upkeep is essential to prevent issues like leaks or performance drops, which can lead to increased downtime.

Pharmaceutical applications also benefit from these pumps. They allow for high precision in active ingredient dosing, crucial in drug formulation. Reports indicate that inaccuracies in dosing can compromise drug efficacy. A small error can have serious consequences. Thus, the accuracy of membrane dosing pumps is essential for patient safety. Yet, not all systems achieve the same level of precision, highlighting the need for continuous improvement.

When evaluating dosing pump technologies, membrane pumps stand out. They excel in precision and reliability. Unlike gear or diaphragm pumps, membrane pumps provide consistent flow rates. They minimize the risk of chemical contamination due to their design. A flexible membrane separates the fluid from the drive mechanism, ensuring purity.

Other dosing technologies may offer higher pressure capabilities. However, they often lack the same level of accuracy in low-flow applications. Gear pumps might not handle viscous fluids well, leading to inefficiencies. Some users experience maintenance issues with diaphragm pumps, which can wear over time. This can result in higher operational costs.

Yet, membrane dosing pumps do have limitations. They may require frequent calibration to maintain accuracy. Users often overlook the cost of replacement membranes. This oversight can lead to unexpected expenses. Balancing these factors is essential for making an informed choice. Consider your specific application needs carefully.

Membrane dosing pumps stand out for their cost-effectiveness in various applications. Their design allows for precise liquid delivery, minimizing waste. Using less energy than traditional pumps, they can significantly reduce operating costs. Maintenance of membrane pumps is generally straightforward, requiring only periodic checks and replacements. This ease can save time and labor expenses over the pump's lifespan.

However, one must consider potential complications. Membrane wear and tear can occur, especially under harsh conditions. This leads to unexpected downtime, which can be costly. Additionally, if not calibrated correctly, flow rates may fluctuate. These factors highlight the importance of regular monitoring and maintenance. Finding the right balance in operation can maximize efficiency and reduce the need for frequent repairs. Proper training for operators is also crucial to minimize errors.